Sep . 25, 2024 19:03 Back to list

ce certification epdm oil tank gasket

EPDM Oil Tank Gaskets and CE Certification A Comprehensive Overview

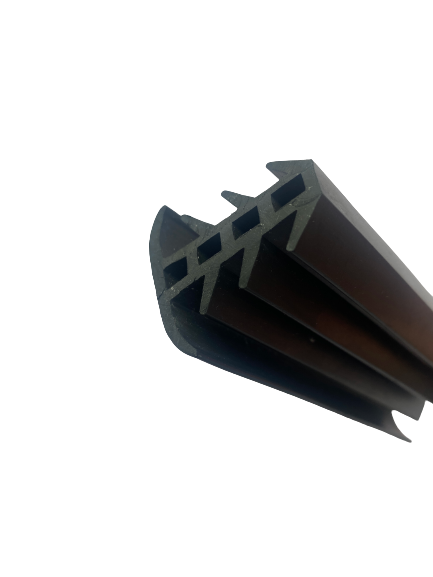

In the world of industrial applications, the materials used to manufacture gaskets must meet strict standards to ensure safety, durability, and efficiency. One of the most commonly used materials for gaskets in oil tanks is Ethylene Propylene Diene Monomer (EPDM). This synthetic rubber is renowned for its excellent resistance to heat, oxidation, and various chemicals, making it an ideal choice for sealing applications in the oil and gas industry. An essential aspect of using EPDM gaskets effectively lies in ensuring they are certified according to relevant regulations, including CE certification.

Understanding EPDM and Its Benefits

EPDM is a type of elastomer that possesses impressive mechanical properties and can be utilized across a wide range of temperatures, often between -40°C to 120°C. This thermal stability is crucial for applications such as oil tanks, where fluctuations in temperature can lead to material failure if the wrong type of gasket is used. In addition to temperature resistance, EPDM exhibits outstanding resistance to aging and environmental factors, such as UV radiation and ozone, which can corrode or degrade other materials.

Furthermore, EPDM is impermeable to various fluids and gases, making it effective in preventing leaks and ensuring the integrity of oil storage tanks. Its flexibility allows for a better seal, accommodating slight changes in the tank's dimensions over time. This adaptability not only prolongs the lifespan of the gasket but also enhances safety by minimizing the risk of leaks that could lead to catastrophic spills.

The Importance of CE Certification

CE certification is a mandatory conformity marking for products sold within the European Economic Area (EEA). It indicates that the product meets health, safety, and environmental protection standards set by the European Union. For EPDM oil tank gaskets, obtaining CE certification signifies that the product has been rigorously tested and complies with the EU's stringent regulations, which is crucial for maintaining the integrity of oil storage systems.

ce certification epdm oil tank gasket

Manufacturers must conduct comprehensive evaluations, including testing for mechanical strength, chemical resistance, and durability under stress. By achieving CE certification, manufacturers not only enhance their credibility in the market but also gain access to a broader customer base, as companies seeking compliant products often prioritize those with recognized certifications.

The Certification Process

The certification process involves several steps, beginning with initial product assessments. Manufacturers must ensure that their gaskets are manufactured from high-quality EPDM that meets the established specifications. Secondly, comprehensive testing must be carried out by authorized laboratories. This testing may evaluate various factors including resilience, resistance to different oils and chemicals, and performance under extreme conditions.

Once testing is complete, manufacturers must prepare technical documentation that includes details about the gasket’s composition, production processes, and test results. This documentation is submitted to a Notified Body, which reviews the material to determine compliance with relevant directives. Upon successful examination, the Notified Body issues the CE marking, allowing the gaskets to be marketed within the EEA.

Conclusion

The use of EPDM oil tank gaskets plays a vital role in ensuring the safety and efficiency of oil storage systems. Their unique properties combined with the assurance of CE certification provide confidence to manufacturers and end-users alike. In an industry where safety and reliability are paramount, utilizing properly certified EPDM gaskets is not just a regulatory requirement but a commitment to excellence. As the oil and gas industry continues to evolve, the demand for high-quality, certified sealing solutions will only grow, underscoring the importance of materials like EPDM in maintaining operational integrity.