Déc . 05, 2024 04:31 Back to list

Customized Marine Fender Seals from Leading Manufacturers for Perfect Application Fit

Marine Fender Seals Customized Solutions for Enhanced Performance

Marine environments pose unique challenges for shipping and dock operations. One critical component ensuring the safety and efficiency of these operations is the marine fender system, particularly the seals that enhance their performance. Customized marine fender seals can provide tailored solutions that meet specific operational needs, ensuring durability, reliability, and enhanced safety across various maritime applications.

Understanding Marine Fender Systems

Marine fender systems are robust structures designed to absorb the kinetic energy of vessels during docking and berthing. They protect both the ships and the docks from impact damage. The seal component of these fender systems is crucial, as it directly affects the fender's ability to perform under varying conditions. Well-designed seals can minimize wear, reduce maintenance costs, and enhance the overall lifespan of the fender system.

The Importance of Customization

While standard marine fender seals might suffice for some applications, many maritime operations require customized solutions to address specific challenges. Factors such as environmental conditions, vessel size, weight, and docking frequency can significantly influence the choice of materials and designs for fender seals.

Customization begins with a thorough assessment of operational needs. Manufacturers often collaborate closely with clients to determine the unique requirements of their docking facilities. This process includes evaluating factors such as

1. Environmental Conditions Marine environments are harsh, often exposed to saltwater, waves, and extreme weather. Custom seals made from materials that resist corrosion and degradation will ensure longevity and reliability.

2. Vessel Characteristics Different vessels have varying sizes and weights. Custom seals can be designed to accommodate the specific dynamics of the vessels they will engage with, optimizing their performance during docking.

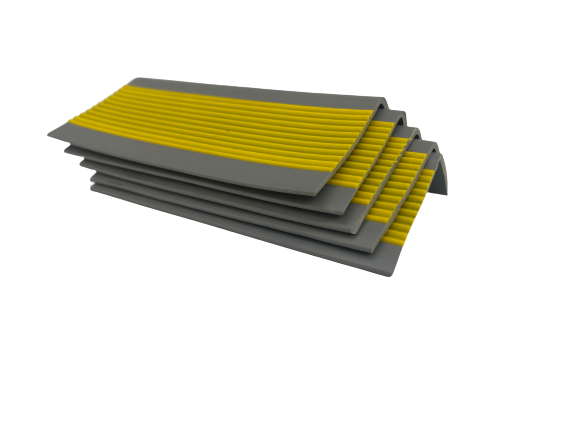

marine fender seals can be customized manufacturer

3. Frequency of Use Facilities that experience high traffic may require seals designed for heavier impact and increased durability. Customized solutions can cater to these high-demand operations, reducing maintenance and replacement costs.

Material Selection for Customized Seals

The material selection for marine fender seals is paramount. Manufacturers often utilize a combination of rubber compounds, polyurethane, and other resilient materials to create seals that withstand the rigors of marine environments. Each material offers distinct benefits

- Natural Rubber Known for its excellent elasticity and impact resistance, natural rubber is often used for seals that require flexibility and durability. - Polyurethane This material offers superior resistance to abrasion, tearing, and aging, making it ideal for high-impact applications.

- Neoprene With its resistance to oils and chemicals, neoprene is suitable for environments where oil spills or chemical exposure are concerns.

By precisely selecting the right materials based on the operational conditions, manufacturers can produce marine fender seals that meet all performance criteria and reduce the total cost of ownership.

Conclusion

Customized marine fender seals play a vital role in the safety and efficacy of maritime operations. By understanding the specific needs of docking environments and leveraging advanced materials, manufacturers can provide tailored solutions that enhance the performance of marine fender systems. In a world where shipping and maritime logistics are increasingly critical, investing in customized fender seals is an investment in safety, longevity, and operational efficiency. Choosing the right manufacturer with expertise in custom solutions ensures that maritime operations can navigate the challenges of the sea with confidence.

Next: