Déc . 10, 2024 05:06 Back to list

oem sealing strip for doors, windows, curtain walls

OEM Sealing Strips for Doors, Windows, and Curtain Walls Ensuring Quality and Efficiency

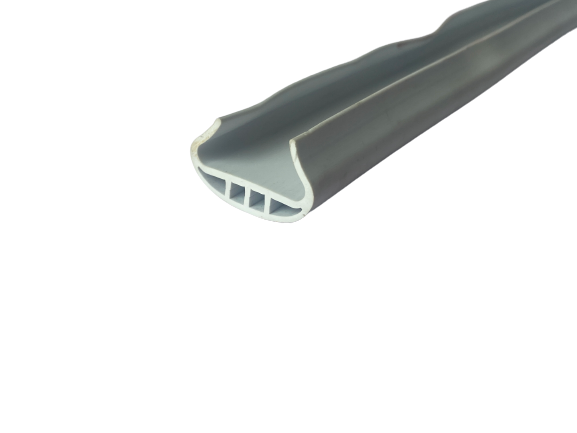

In today's competitive construction and manufacturing industries, the demand for high-quality sealing solutions has seen a significant rise. Among these, OEM (Original Equipment Manufacturer) sealing strips have gained prominence as essential components for doors, windows, and curtain walls. These sealing strips not only enhance the functionality of architectural elements but also contribute to energy efficiency and overall structural integrity.

Understanding OEM Sealing Strips

OEM sealing strips serve as critical interfaces that prevent air, water, dust, and noise infiltration. They are designed to fit specific dimensions provided by original equipment manufacturers, ensuring precision and compatibility with various door and window models. The customization options available with OEM sealing strips mean that manufacturers can meet the exact specifications required for different applications, ranging from residential buildings to commercial structures.

Materials Used in OEM Sealing Strips

The efficacy of sealing strips largely depends on the materials used in their construction. Common materials include

1. EPDM (Ethylene Propylene Diene Monomer) Rubber Known for its excellent weather resistance and durability, EPDM is widely used in outdoor applications. Its ability to withstand extreme temperatures makes it suitable for a variety of climates.

2. PVC (Polyvinyl Chloride) PVC sealing strips are versatile and economical. They offer good sealing capabilities and are resistant to chemicals and UV exposure, making them a popular choice for numerous building applications.

3. Silicone Known for its superior flexibility and high-temperature resistance, silicone sealing strips are ideal for environments with temperature fluctuations. They provide excellent sealing performance and longevity.

4. Foam Materials Soft foam sealing strips are beneficial for acoustic insulation and thermal barriers. They are often used in applications where soundproofing is crucial, such as in residential apartments or office buildings.

Application of OEM Sealing Strips

oem sealing strip for doors, windows, curtain walls

1. Doors Whether for entry doors, interior doors, or patio doors, sealing strips play a vital role in enhancing security and comfort. By preventing drafts and moisture ingress, they contribute to a more stable indoor environment and protect the integrity of the door structure.

2. Windows Windows represent a significant area for heat loss in buildings. OEM sealing strips are used around window frames to create tight seals, increasing energy efficiency and reducing heating and cooling costs. Furthermore, they help in minimizing noise pollution from the outside.

3. Curtain Walls In modern architecture, curtain walls have become a popular choice due to their aesthetic appeal and functionality. Sealing strips are used to ensure that these large panels are watertight and air-tight, providing building occupants with a comfortable interior while preserving the exterior's sleek design.

Benefits of Using OEM Sealing Strips

The advantages of incorporating OEM sealing strips into construction processes are manifold

- Improved Energy Efficiency By minimizing air and water leaks, OEM sealing strips contribute significantly to energy saving in buildings, making them an essential component for sustainable construction.

- Enhanced Comfort Well-sealed doors and windows help maintain a stable indoor temperature, leading to increased comfort for residents and employees alike.

- Longevity and Durability Properly installed sealing strips protect against the elements, ensuring that doors and windows have a longer lifespan and reducing maintenance costs.

- Customizable Solutions OEM sealing strips can be tailored to meet specific requirements, allowing manufacturers to offer a variety of designs and functionalities for diverse applications.

Conclusion

In conclusion, OEM sealing strips for doors, windows, and curtain walls are critical components that enhance the performance of architectural structures. By choosing the right materials and ensuring proper installation, builders and manufacturers can significantly improve energy efficiency, comfort, and durability in their projects. As the demand for sustainable building solutions continues to grow, the importance of high-quality OEM sealing strips cannot be overstated. Their role in modern architecture is vital, making them indispensable in achieving both aesthetic appeal and functional excellence in building design.

Next:

Prev: