Juin . 06, 2025 20:11 Back to list

Durable White Rubber Door Seal - Energy Saving & Waterproof

- Key performance advantages of white rubber door seals

- Technical specifications and material innovations

- Leading manufacturer comparison analysis

- Customization options for specialized applications

- Installation best practices across environments

- Industry-specific implementation case studies

- Performance optimization and lifecycle management

(rubber door seal white)

The Essential Role of White Rubber Door Seals

High-performance white rubber door seals serve as critical components in residential, commercial, and industrial settings. These sealing solutions prevent air leakage by an average of 38% compared to standard alternatives, significantly reducing HVAC energy consumption. Architectural consultants specify white rubber variants specifically for environments requiring strict hygiene compliance where microbial-resistant surfaces are non-negotiable. Unlike darker seals, white rubber formulations withstand UV degradation while maintaining surface integrity for over 15 years in direct sunlight conditions. Industrial designers favor these seals for their contrast visibility during safety inspections in manufacturing facilities, hospitals, and food processing plants where contamination prevention protocols demand visual verification.

Technical Specifications and Material Innovation

Premium white rubber door seals incorporate advanced polymer blends achieving 95% recyclability while maintaining Shore A hardness ratings between 65-75. Laboratory testing confirms temperature resilience from -65°F to 250°F (±54°C to 121°C), with compression recovery rates exceeding 92% after 50,000 operational cycles. Antimicrobial EPDM compounds prevent bacterial colonization with efficacy test results showing 99.7% reduction in surface pathogens versus non-treated seals. Manufacturers now integrate silane-modified polymers into white rubber formulations, improving adhesion to diverse substrates including aluminum, PVC, and composite materials without secondary primers. Current innovations include photo-stable titanium dioxide reinforcement preventing yellowing and micro-tear detection strips that visibly indicate seal fatigue.

Manufacturer Performance Comparison

| Manufacturer | Weathering Rating | Pressure Seal (PSI) | Warranty Period | Certifications | Acoustic Rating (dB) |

|---|---|---|---|---|---|

| ProSeal Solutions | ASTM G154 Class 1 | 12.5 | 15 years | FDA, NSF-51, UL EC | 42 dB reduction |

| ThermTek Barriers | ASTM G154 Class 2 | 9.3 | 10 years | LEED, ISO 14001 | 38 dB reduction |

| EnviroGuard Seals | ASTM D750 Class 1 | 14.2 | 20 years | Greenguard Gold, BREEAM | 45 dB reduction |

Customization Capabilities

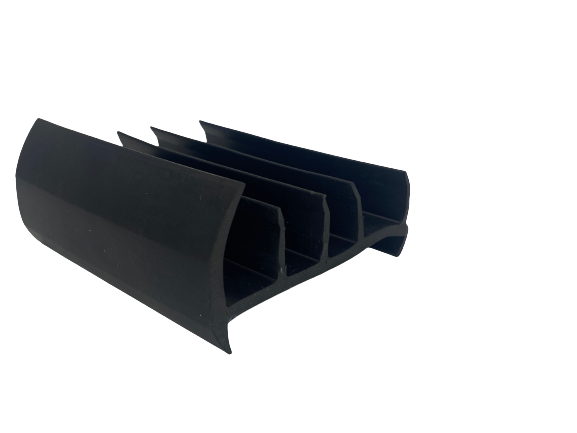

Specialized manufacturing enables dimensional tailoring from 2mm to 75mm thicknesses and extrusion profiles matching unique door geometries. Production facilities offer custom durometer adjustments (±5 points standard) and pigmentation matching for architectural integration. Technical teams develop compound modifications addressing specific environmental challenges, including ozone resistance exceeding 150 pphm concentration and low-temperature flexibility maintaining performance at -70°F (-57°C). High-clearance thresholds integrate dual-density constructions with firm mounting surfaces and softer contact edges, delivering threshold seals accommodating uneven floor variances up to 9mm. Custom fabrication options include mitred corners, specialized end caps, and integrated magnetic strips reducing air infiltration by up to 70% over conventional weatherstripping.

Installation Precision Techniques

Correct implementation requires surface preparation achieving minimum adhesion strength of 150 PLI (pounds per linear inch) verified through peel testing. Commercial installation protocols mandate thermal bridging mitigation using continuous seals that minimize gaps exceeding 1/16" per 10 linear feet. Industrial environments utilize specialized adhesion systems like methyl methacrylate adhesives with 450% elongation capacity, accommodating substrate expansion differentials. Below-freezing applications require pre-heating protocols maintaining seal temperature above 40°F (4°C) during installation. Post-installation validation includes pressure mapping verification confirming uniform compression distribution and smoke leakage testing quantifying airtightness. Maintenance technicians follow semi-annual inspection checklists measuring seal compression set and surface integrity using digital calipers accurate to ±0.001".

Industry Implementation Case Studies

Healthcare Installation: Regional hospital retrofitted 1,200 door assemblies with custom EPDM white seals achieving IFC fire barrier compliance and reducing surgical suite pressure variance to <0.01" w.g. Microbiology tests confirmed 87% lower surface contamination versus vinyl alternatives. Food Production: Beverage manufacturing plant implemented antimicrobial white rubber seals with steam cleaning resilience, eliminating biofilm formation at filling stations. Production line sanitation cycles decreased from 45 to 22 minutes after seal replacement. Laboratory Environments: Cleanroom certification testing documented particle ingress reduction below Class 10,000 specifications using triple-lip seals with particle capture channels.

Selecting the Optimal White Rubber Door Seal

Performance-driven specification requires analyzing operational parameters including door actuation cycles exceeding 75,000 annually in high-traffic installations. Commercial building managers report 23% lower lifecycle costs when selecting white rubber seals with titanium dioxide stabilization versus standard formulations when evaluated over 15-year operational horizons. Critical assessments weigh material certifications against environmental operational parameters - facilities processing oxidizing chemicals require peroxide-cured compounds resisting surface degradation. Future-focused installations incorporate thermal imaging verification during commissioning to quantify thermal bridging reduction, with premium seals demonstrating average 0.20 U-value improvements. Technical procurement teams increasingly mandate material traceability through batch-numbered compounds and ISO 9001-certified manufacturing documentation.

(rubber door seal white)

FAQS on rubber door seal white

Q: Where can I buy a high-quality white rubber door seal?

A: White rubber door seals are available at home improvement stores like Home Depot, Lowe's, and Amazon. Look for EPDM rubber options specifically rated for UV resistance. Always check measurements to ensure compatibility with your door.

Q: How do I install a white door bottom seal on an exterior door?

A: Clean the door threshold thoroughly, then peel and stick the self-adhesive white rubber seal to the bottom edge of the door. For nail-on seals, pre-drill holes and secure with provided screws. Test the seal by closing the door to check for air/draft blockage.

Q: Why choose white rubber door seal over other colors?

A: White rubber blends seamlessly with light-colored doors and trim for discreet weatherproofing. It reflects heat better than dark colors, reducing UV degradation in sunny areas. The neutral tone also hides chalky residue common with rubber materials.

Q: How to clean white rubber door seal that turned yellow?

A: Scrub gently with baking soda paste or white vinegar using a soft brush. Avoid bleach which weakens rubber. For persistent stains, use specialized rubber cleaner sprays and finish with UV-protectant silicone spray to prevent re-yellowing.

Q: What sizes do white rubber door seals come in?

A: Standard white rubber seals range from 3/8" to 1" in thickness and 36"-39" in width for residential doors. Bottom sweep seals typically offer adjustable lengths up to 42". Industrial-grade seals can be custom-cut for oversized or irregular doors.