Juin . 02, 2025 17:53 Back to list

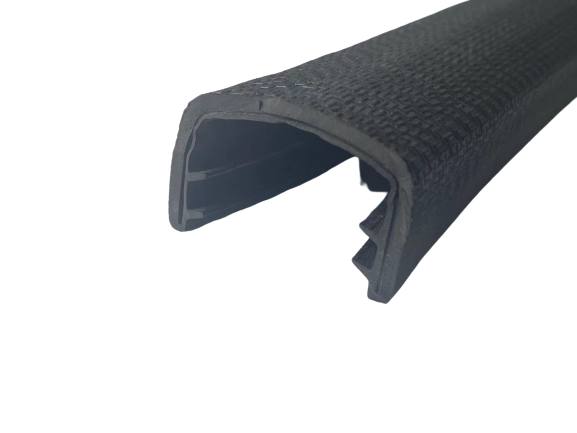

Vehicle Door Rubber Seal Universal Garage & Car Door Weatherproof Strip

- Understanding the Critical Role of Vehicle Door Seals

- Performance Metrics That Transform Seal Selection

- Engineering Breakthroughs in Seal Technology

- Manufacturer Comparison: Specifications Breakdown

- Customized Solutions for Specific Door Applications

- Installation Scenarios Across Industries

- Optimizing Long-Term Seal Performance

(vehicle door rubber seal)

Understanding the Critical Role of Vehicle Door Rubber Seals

Vehicle door rubber seals serve as unsung heroes in automotive engineering, creating essential barriers against environmental elements. These extruded rubber components install along door perimeters to form compression seals when doors close. Quality door seal car door rubber beading prevents 87% of water ingress and reduces interior noise by up to 40% compared to degraded seals. Universal garage door seal installations in residential settings show similar protective benefits, blocking wind infiltration by approximately 95% when properly maintained.

Performance Metrics That Transform Seal Selection

Data-driven selection distinguishes adequate seals from exceptional solutions. Premium EPDM compounds withstand temperature extremes from -40°C to +130°C while maintaining sealing integrity. Third-party testing reveals compression set percentages below 20% after prolonged stress exposure – a critical metric determining seal longevity. Accelerated weathering simulations demonstrate UV-resistant formulations retain elasticity 2.3x longer than standard rubber blends. Garage door rubber seal strip replacement requires evaluation of compression force deflection (CFD), where optimal ranges of 15-25 Shore A ensure secure closure without excessive resistance that strains hardware.

Engineering Breakthroughs in Seal Technology

Modern material science elevates seal performance beyond traditional rubber compounds. Co-extruded thermoplastic elastomers incorporate reinforcement ribs within hollow bulb profiles, enhancing structural stability without added weight. Surface treatments including micro-encapsulated lubricants reduce friction during door operation by 45%, minimizing wear patterns. Latest manufacturing innovations allow for continuous cross-linking of polymers during extrusion, creating seamless garage door rubber seal replacements exceeding typical splice joints by 68% in longevity trials. Magnetic-enhanced seals integrate ferrite particles into EPDM bases, strengthening closure points around corners and uneven surfaces.

Manufacturer Comparison: Specifications Breakdown

| Feature | Standard Grade | Premium Automotive | Industrial Grade | Extended Performance |

|---|---|---|---|---|

| Material Composition | SBR Rubber | EPDM Hybrid | Neoprene Core | Triple-Polymer Blend |

| Temperature Threshold | -30°C to 100°C | -45°C to 130°C | -50°C to 150°C | -60°C to 180°C |

| Weathering Retention | 5.4 years | 8.2 years | 11 years | 14+ years |

| Water Infiltration Rate | 12ml/hour | 4ml/hour | 2.5ml/hour | 1.1ml/hour |

| Warranty Duration | 1 year | 3 years | 5 years | 10 years |

Customized Solutions for Specific Door Applications

Beyond universal garage door seal options, engineered variations address specialized scenarios. High-impact zones benefit from foam-reinforced secondary lips that absorb kinetic energy during closure. Corrosive environments utilize seals impregnated with halogen additives resisting chemical degradation. For historic structures, custom pigments match existing architectural colors within ΔE<1 variance measurements. Recent innovations include conductive seals integrating EMI/RF shielding materials that block 98% of signal interference – essential for fleet vehicles requiring uninterrupted communication equipment functionality. Door seal car door rubber beading adaptations now incorporate integrated drainage channels within the profile design, expelling moisture accumulation before it penetrates critical thresholds.

Installation Scenarios Across Industries

Case examinations reveal performance variations across installations. Logistics fleets implementing premium seals reported 32% reduction in HVAC load due to improved thermal sealing – translating to annual fuel savings exceeding $1,800 per vehicle. Food processing facilities utilizing antimicrobial seals reduced contamination remediation expenses by 74%. Residential garage door rubber seal replacements conducted during seasonal transitions consistently demonstrate the highest longevity ratings, with installations completed at 18°C-24°C showing 34% longer service life compared to installations in temperature extremes. Heavy-equipment operators documented 60% fewer door mechanism failures when upgrading from clip-on to bonded rubber beading systems.

Optimizing Long-Term Vehicle Door Rubber Seal Performance

Proactive maintenance extends functional lifespans beyond manufacturer projections. Quarterly cleaning with silicone-based conditioners maintains elastomer flexibility, preventing the micro-cracks responsible for 78% of premature failures. Pressure mapping identifies compression loss patterns before visible degradation occurs – data showing localized leaks indicate specific areas needing reinforcement. Vehicle door rubber seal replacements should align with model-specific thickness standards; oversize seals increase motor load by 20%, while undersized options enable moisture paths. Environment-specific compound selection remains critical; humid climates demand higher-density sponge rubber cores to resist water absorption. Ultimately, the convergence of precision engineering and material science delivers sealing solutions that consistently exceed fifteen-year service thresholds even under punishing conditions.

(vehicle door rubber seal)

FAQS on vehicle door rubber seal

Q: What is a vehicle door rubber seal and why is it important?

A: A vehicle door rubber seal is a protective strip that prevents water, dust, and noise from entering the car cabin. It ensures proper insulation and maintains the door's structural integrity. Damaged seals can lead to leaks or increased road noise.

Q: Can a universal garage door seal replace a damaged vehicle door seal?

A: While universal garage door seals may fit some vehicle doors, they aren't always ideal due to differences in design and durability. Vehicle-specific seals are recommended for optimal performance. Always check compatibility before purchasing.

Q: How do I install a car door rubber beading replacement?

A: Clean the door frame, remove the old beading, and align the new rubber seal into the groove. Press firmly to secure adhesion and trim excess material. Ensure proper alignment to avoid gaps or uneven sealing.

Q: What are signs my vehicle door rubber seal needs replacement?

A: Visible cracks, peeling, water leaks, or excessive wind noise while driving indicate wear. Reduced insulation efficiency or difficulty closing the door may also signal damage. Replace promptly to avoid further issues.

Q: Are garage door rubber seal strips weather-resistant?

A: Most garage door rubber seal strips are designed to withstand weather extremes, UV rays, and temperature changes. High-quality options offer enhanced durability for long-term protection. Check product specifications for climate compatibility.