Oct . 21, 2024 02:18 Back to list

High-Quality 4% Neoprene Rubber Sheet for Versatile Applications and Durability

The Versatility and Applications of 1% 204% Neoprene Rubber Sheet

Neoprene rubber, also known as polychloroprene, is a synthetic rubber that has gained popularity due to its excellent properties and wide range of applications. Among the various grades and formulations of neoprene, the 1% 204% neoprene rubber sheet stands out for its unique characteristics. This article explores the features, benefits, and diverse applications of this specific neoprene rubber sheet.

Understanding Neoprene Rubber

Neoprene was first developed in the 1930s and has since become a staple material in various industries. It is renowned for its durability, flexibility, and resistance to temperature fluctuations, chemicals, and UV radiation. These traits make neoprene an ideal choice for applications that require resilience in challenging environments. The specific formulation of 1% 204% neoprene rubber implies a unique blend of tensile strength and elasticity, making it suitable for numerous applications.

Unique Characteristics of 1% 204% Neoprene Rubber Sheet

The 1% 204% neoprene rubber sheet is characterized by its blend of properties that ensure both durability and performance. The 1% typically indicates additive compounds that enhance certain physical properties without compromising the rubber's inherent qualities. On the other hand, 204% suggests the level of elasticity and strength, indicating that the material can be stretched significantly while maintaining its shape and integrity.

1. Chemical Resistance One of the notable features of neoprene rubber is its resistance to a variety of chemicals, including oils, solvents, and other hazardous materials. This characteristic is particularly important in industrial applications where exposure to such substances is common.

2. Temperature Stability Neoprene can withstand a broad range of temperatures, making the 1% 204% sheets suitable for both hot and cold environments. This property is essential in industries such as automotive, aerospace, and construction.

3. Water Resistance The rubber is inherently resistant to water and moisture, which adds to its versatility. As a result, it is often used in applications involving waterproofing and sealing.

4. Excellent Insulation Properties Neoprene offers good thermal and electrical insulation, making it a preferred choice in applications that require protection against temperature fluctuations or electrical conductivity.

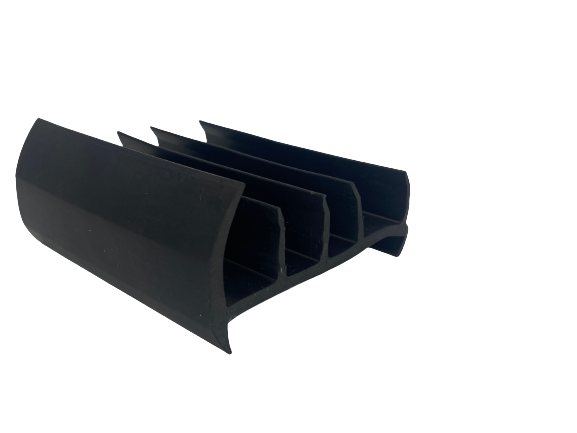

1 4 neoprene rubber sheet

Applications of 1% 204% Neoprene Rubber Sheet

The applications of 1% 204% neoprene rubber sheets are extensive and span multiple industries. Here are some of the most common applications

1. Industrial Seals and Gaskets Due to its chemical resistance and durability, neoprene rubber sheets are widely used to manufacture seals and gaskets. These components are crucial in preventing leaks in pipes, tanks, and machinery.

2. Automotive Parts In the automotive industry, neoprene is often utilized for components like belts, hoses, and insulators, where durability and resistance to oils are paramount.

3. Marine Applications The water-resistant properties of neoprene make it an excellent choice for marine applications, including boat fenders, seals, and components that require both flexibility and protection against harsh marine environments.

4. Sports Gear The elasticity and comfort of neoprene rubber sheets have led to their widespread use in sports accessories, including wetsuits, knee braces, and padding for protective gear.

5. Construction Materials Neoprene is used in building materials such as roofing membranes, tiles, and pads designed to absorb shock and vibrations.

6. Medical Equipment In the medical field, neoprene is utilized for elastic bandages, braces, and other equipment that require both flexibility and support.

Conclusion

The 1% 204% neoprene rubber sheet offers a remarkable blend of durability, flexibility, and resistance to environmental challenges, making it a vital component in numerous industries. Its unique properties cater to a wide range of applications, from automotive and marine to medical and construction. As industries continue to evolve and demand materials that can withstand harsh conditions while providing reliability, the versatility of 1% 204% neoprene rubber sheets will undoubtedly play a critical role in future innovations.