Jan . 25, 2025 02:26 Back to list

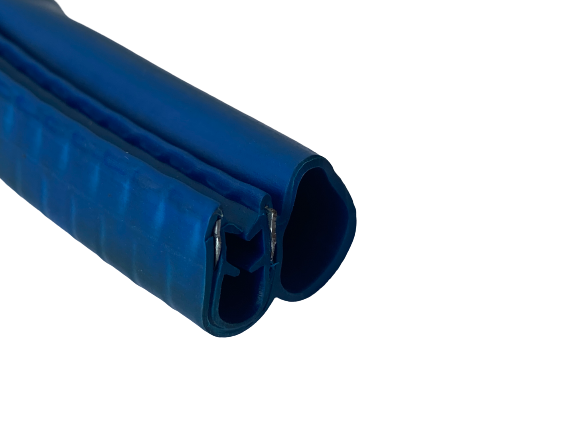

custom marine fender rubber sealing strip

Custom marine fender rubber sealing strips are an essential component for maritime applications, renowned for their durability, adaptability, and efficacy in protecting vessels and structures. These sealing strips are particularly crucial when considering the harsh marine environment, where exposure to saltwater, ultraviolet rays, and temperature fluctuations can be relentless. They not only ensure the longevity of marine fenders but also enhance the safety and performance of maritime operations.

Authoritativeness in this field is supported by industry standards and certifications that these products often adhere to. Compliance with regulations such as the International Maritime Organization (IMO) guidelines further reinforces their credibility. Manufacturers who pursue and maintain such certifications underscore their commitment to quality and safety, assuring customers that their products meet or exceed international standards for marine applications. Trust in these products is built over years of reliable service and is buttressed by testimonials from satisfied clients. Shipowners, port authorities, and maritime engineers alike have praised the performance and resilience of custom marine fender rubber sealing strips. Case studies highlighting successful deployments offer potential customers insights into the advantages these products bring, helping them make informed decisions. In conclusion, custom marine fender rubber sealing strips offer robust protection and performance in challenging maritime environments. With their superior material properties, expert engineering, and adherence to strict standards, they are a trusted choice for ensuring safety and efficiency in maritime operations. Whether protecting the hull of a supertanker or the docks of a busy harbor, these sealing strips offer unmatched reliability and longevity, making them an indispensable asset in the marine industry. The investment in quality custom strips pays dividends through reduced maintenance costs, increased safety, and the sustained integrity of marine infrastructure, illustrating why they are trusted around the globe.

Authoritativeness in this field is supported by industry standards and certifications that these products often adhere to. Compliance with regulations such as the International Maritime Organization (IMO) guidelines further reinforces their credibility. Manufacturers who pursue and maintain such certifications underscore their commitment to quality and safety, assuring customers that their products meet or exceed international standards for marine applications. Trust in these products is built over years of reliable service and is buttressed by testimonials from satisfied clients. Shipowners, port authorities, and maritime engineers alike have praised the performance and resilience of custom marine fender rubber sealing strips. Case studies highlighting successful deployments offer potential customers insights into the advantages these products bring, helping them make informed decisions. In conclusion, custom marine fender rubber sealing strips offer robust protection and performance in challenging maritime environments. With their superior material properties, expert engineering, and adherence to strict standards, they are a trusted choice for ensuring safety and efficiency in maritime operations. Whether protecting the hull of a supertanker or the docks of a busy harbor, these sealing strips offer unmatched reliability and longevity, making them an indispensable asset in the marine industry. The investment in quality custom strips pays dividends through reduced maintenance costs, increased safety, and the sustained integrity of marine infrastructure, illustrating why they are trusted around the globe.

Next:

Prev: