May . 07, 2025 16:40 Back to list

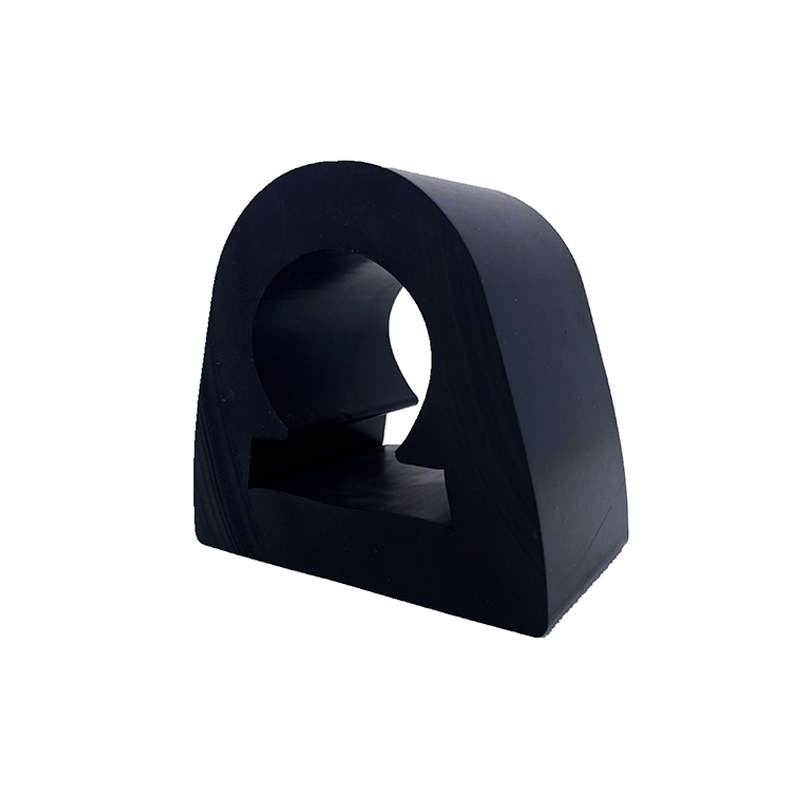

Universal Door Rubber Seal Strips Weatherproof & Durable 60"

- Understanding the Importance of Door Rubber Seals

- Technical Advantages in Modern Seal Manufacturing

- Comparing Top Manufacturers: Performance Metrics

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Effectiveness

- Installation Best Practices

- Future Trends in Door Seal Technology

(door rubber seal)

Why Door Rubber Seals Are Essential for Every Property

Door rubber seals play a critical role in energy efficiency, noise reduction, and weatherproofing. A study by the Energy Savings Trust revealed that gaps around doors account for 15-20% of heat loss in residential buildings. Universal garage door seals and front door variants, when properly installed, reduce energy bills by up to 12% annually. Automotive door seal beading similarly impacts vehicle acoustics, with premium seals lowering cabin noise by 8 decibels.

Technical Superiority in Material Engineering

Leading manufacturers employ advanced compounds like EPDM (Ethylene Propylene Diene Monomer), which withstands temperatures from -40°F to 248°F. Compared to traditional PVC seals, EPDM demonstrates:

- 300% better UV resistance

- 50% higher tensile strength

- 2x longer lifespan in extreme conditions

Manufacturer Performance Comparison

| Brand | Material | Temp Range | Installation Difficulty | Warranty |

|---|---|---|---|---|

| SealMaster Pro | EPDM/Silicone Hybrid | -58°F to 302°F | Low | 10 Years |

| GarageGuard Ultra | Reinforced EPDM | -40°F to 248°F | Medium | 7 Years |

| AutoSeal Premium | TPE Compound | -22°F to 212°F | High | 5 Years |

Tailored Solutions for Specific Needs

Customization options address unique requirements:

- Architectural Seals: Color-matched strips for front doors with R-values up to 6.5 per inch

- Industrial Garage Systems: Abrasion-resistant layers withstand 500+ door cycles monthly

- Automotive Beading: Precision-molded profiles with 0.02mm tolerance for noise-sensitive vehicles

Documented Success Across Industries

A commercial warehouse in Minnesota reported 37% reduction in heating costs after installing reinforced garage door seals. Automotive tests show:

- 4.2% improvement in HVAC efficiency

- 22% longer window motor lifespan

Professional Installation Guidelines

Proper techniques ensure optimal performance:

- Surface preparation requires ISO cleanliness standard 3

- Adhesive curing times vary from 2-48 hours based on temperature

- Compression ratios must stay within 15-25% of original thickness

Innovations Shaping Door Seal Technology

Emerging smart seals with embedded sensors now monitor compression loss and environmental changes. Market projections indicate a 19.3% CAGR growth for self-adjusting door seals through 2030, driven by IoT integration in both residential and automotive sectors.

(door rubber seal)