Oct . 22, 2024 09:43 Back to list

EPDM Rubber Sheets for Versatile Applications in Construction and Manufacturing

Understanding EPDM Rubber and Its Applications

EPDM rubber, or ethylene propylene diene monomer rubber, is a versatile synthetic rubber that is widely used in various industries due to its unique properties. Initially developed in the mid-20th century, EPDM has gained popularity for its excellent resistance to heat, ozone, and weathering, making it particularly suitable for outdoor applications. This article aims to provide a comprehensive overview of EPDM rubber and its common uses, specifically focusing on EPDM rubber sheets.

Properties of EPDM Rubber

EPDM rubber is known for its outstanding durability and flexibility, which stem from its unique molecular structure. Its composition allows it to withstand extreme temperature variations, ranging from -40°F to 212°F (-40°C to 100°C), without compromising its physical integrity. Furthermore, EPDM exhibits remarkable resistance to UV radiation, oxidation, and various chemicals, making it a reliable choice for applications where exposure to harsh environmental conditions is a concern.

Another notable characteristic of EPDM is its excellent electrical insulation properties, making it a popular material for electrical and automotive applications. Additionally, it is non-toxic and has good tensile strength, enhancing its versatility further.

EPDM Rubber Sheets

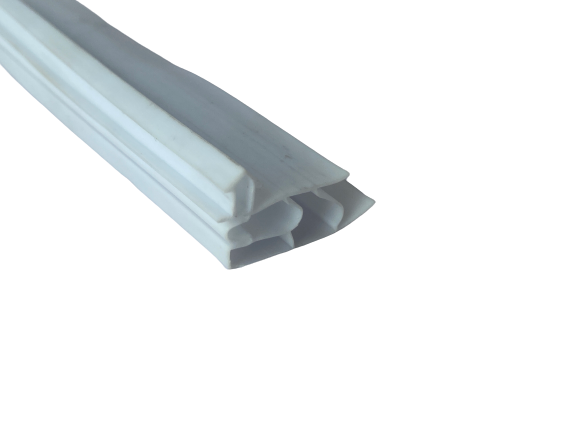

One of the most common forms of EPDM rubber is the rubber sheet. EPDM rubber sheets are manufactured in various thicknesses and sizes, making them suitable for a wide range of applications. These sheets can be easily cut, shaped, and bonded, which adds to their utility in different environments.

Applications of EPDM Rubber Sheets

epdm rubber epdm rubber sheet

1. Roofing Systems EPDM rubber sheets are extensively used in the construction industry, particularly for roofing membranes. Their weather-resistant properties make them ideal for flat or low-slope roofs, providing water-resistant barriers while allowing for easy installation and maintenance.

2. Automotive Industry In the automotive sector, EPDM sheets are utilized for gaskets, seals, and trim. Their ability to endure harsh conditions, along with their non-toxic nature, ensures that they can effectively prevent leaks and protect vehicle components from environmental damage.

3. Industrial Applications EPDM rubber sheets find their place in various industrial applications, including manufacturing conveyor belts, protective covers, and mats. Their resilience enhances safety and durability in environments that demand heavy-duty materials.

4. Electrical Insulation The electrical insulation properties of EPDM make it suitable for applications in the electrical industry. Rubber sheets are often used to manufacture protective coverings for wires and cables, ensuring safety in electrical installations.

5. HVAC Systems Furthermore, EPDM rubber sheets are commonly used in heating, ventilation, and air conditioning (HVAC) systems. They can be employed in ductwork for their thermal resistance and ability to minimize noise transmission.

Conclusion

In summary, EPDM rubber is a remarkably durable and versatile material with a wide range of applications across various industries. The ability to form EPDM rubber into sheets further enhances its usability, making it an essential component in roofing, automotive, industrial, and electrical applications. As the demand for reliable and long-lasting materials continues to rise, EPDM rubber sheets will undoubtedly play a significant role in ensuring the efficiency and safety of numerous products and structures. Understanding the properties and applications of EPDM rubber can aid those in relevant industries in making informed decisions regarding material selection. As a result, the future of EPDM rubber remains bright, backed by ongoing innovations and advancements in material science.