Dec . 18, 2024 18:48 Back to list

marine fender sealing strip factory

Marine Fender Sealing Strip Factory A Crucial Component in Marine Safety

In today's maritime industry, the safety and integrity of vessels are paramount. One critical component that often goes unnoticed yet plays a vital role in ensuring safe docking operations is the marine fender sealing strip. These strips, designed to absorb the impact of a vessel as it docks, protect both the ship and the berthing structure. In this article, we will explore the significance of marine fender sealing strips and the factories that produce them.

What is a Marine Fender Sealing Strip?

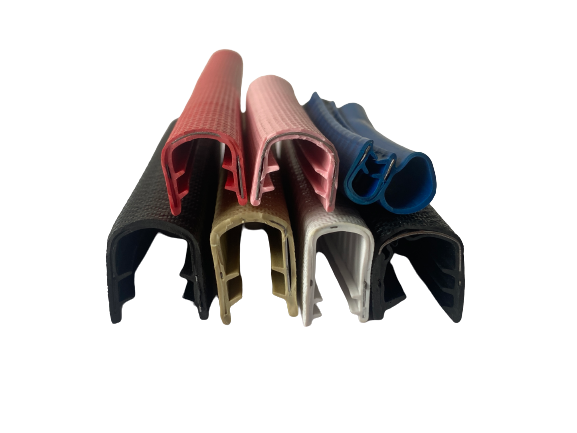

A marine fender sealing strip is a specialized product made from high-quality materials, typically rubber or polyurethane, designed to enhance the functionality of marine fender systems. These sealing strips act as a protective barrier, preventing water ingress and minimizing damage to the vessel and the docking structure. The design of these strips allows them to absorb shocks while also providing a snug fit around the fender, thus minimizing potential wear and extending the life of the fender system.

Importance of High-Quality Manufacturing

The quality of marine fender sealing strips is crucial for ensuring safety and performance in demanding marine environments. Therefore, factories that specialize in the production of these strips must adhere to stringent quality control standards. Such manufacturers utilize advanced technologies and high-grade materials to ensure that their products can withstand the challenges posed by harsh marine conditions, including saltwater, extreme temperatures, and heavy impact from vessels.

Key Features of Marine Fender Sealing Strips

Marine fender sealing strips are characterized by several key features that make them highly effective

1. Durability Made from resilient materials, these strips are engineered to resist wear and tear over time while maintaining their structural integrity.

marine fender sealing strip factory

3. Resistance to Marine Environment High-quality sealing strips are resistant to seawater, UV radiation, and temperature fluctuations, ensuring longevity and reliability in various conditions.

4. Ease of Installation Many manufacturers design their sealing strips for quick and easy installation, reducing downtime during docking operations.

The Role of Factories in Production

Factories specializing in marine fender sealing strips play a crucial role in the supply chain of marine safety equipment. These factories are equipped with state-of-the-art machinery and skilled labor that specialize in the production of high-performance sealing strips. The manufacturing process typically involves several key stages, including material selection, molding, curing, and quality testing.

1. Material Selection The choice of materials is fundamental; manufacturers often source premium-grade rubbers and polymers to ensure their products meet industry standards.

2. Molding and Curing Modern factories utilize advanced molding techniques to shape the sealing strips accurately. Curing processes such as vulcanization enhance the materials' toughness and durability.

3. Quality Control After production, sealing strips undergo rigorous testing to ensure they meet safety and performance benchmarks. This quality assurance process is critical to minimizing failures in marine applications.

Conclusion

Marine fender sealing strips may seem like a minor component in the larger context of maritime operations, but their importance cannot be overstated. They contribute significantly to the safety of vessels, protect docking structures, and enhance overall operational efficiency. The factories that produce these essential components are committed to delivering high-quality and reliable products that meet the demands of the marine industry. As the maritime sector continues to evolve, the role of advanced manufacturing in producing marine fender sealing strips will remain a cornerstone in ensuring maritime safety and operational success. Investing in high-quality sealing strips is not just a choice; it’s an imperative for every stakeholder in the maritime industry who prioritizes safety and durability.

Next:

Prev: