Nov . 06, 2024 06:08 Back to list

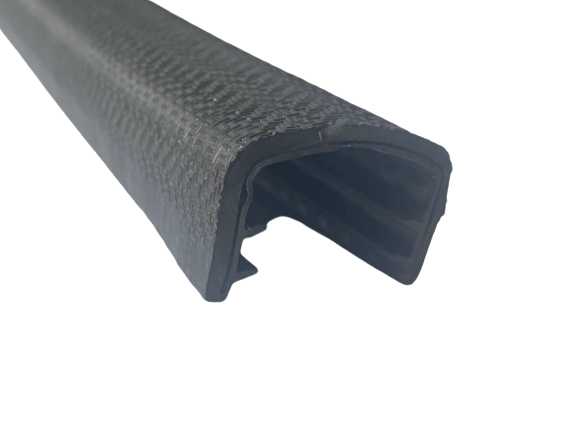

Custom Marine Fender Seals for Unique Applications and Maximum Performance

Customizable Marine Fender Seals Tailoring Solutions for Maritime Needs

In the maritime world, protection and durability are paramount. Whether it’s for ship docking facilities, offshore platforms, or mooring systems, the importance of marine fender seals cannot be overstated. These seals serve as crucial components, absorbing the impact of vessels during docking maneuvers, thereby protecting both the ship and the docking infrastructure. However, not all marine environments are the same, and that’s where the customization of marine fender seals comes into play.

Understanding Marine Fender Seals

Marine fender seals are designed to mitigate the risk of damage caused by the constant motion and forces generated by moored vessels. They are typically made from high-quality materials that resist corrosion, wear, and harsh marine conditions. The primary function of these seals is to absorb energy during impact, ensuring that both boats and infrastructure remain undamaged.

Why Customization Matters

Every marine environment presents unique challenges. Factors such as tidal movements, wave action, weather conditions, and vessel sizes can significantly influence the design and specification of marine fender seals. Here are a few reasons why customization is essential

1. Specific Vessels' Requirements Different vessels have varying sizes, weights, and docking speeds. A one-size-fits-all approach fails to address the specific requirements of each type of vessel. Custom fender seals can be designed to accommodate the unique characteristics of individual vessels or fleets.

2. Environmental Considerations Marine environments can be harsh and unpredictable. Customization allows for the selection of materials that are specifically chosen for their ability to withstand local environmental conditions, such as salinity, temperature fluctuations, and biological growth.

3. Impact Absorption The level of impact absorption required can vary dramatically. Custom fender seals can be engineered to deliver the necessary compression and rebound characteristics required for different docking scenarios, ensuring optimal protection.

marine fender seals can be customized quotes

4. Integration with Existing Infrastructure Ports and docking facilities often have unique physical layouts. Custom seals can be designed to fit seamlessly into existing infrastructure, enhancing functionality while maintaining aesthetic considerations.

5. Cost Efficiency By customizing marine fender seals to meet specific needs, organizations can avoid the costs associated with over-engineered solutions or frequent repairs due to inadequate protection.

The Customization Process

The process of customizing marine fender seals typically involves collaboration between manufacturers and clients. It begins with an assessment of the specific needs of the client, including

- Analysis of the types of vessels that will be using the docking facility. - Evaluation of environmental conditions and potential hazards. - Assessment of the existing facilities and necessary integration points.

Once these factors are assessed, manufacturers can design fender seals with the appropriate dimensions, material properties, and technical specifications. Prototyping and testing are crucial steps in this process to ensure that the final product meets all performance expectations.

Conclusion

In the dynamic and demanding field of maritime operations, customizable marine fender seals are a vital component for ensuring safety and efficiency. By tailoring solutions to the unique needs of individual vessels and environmental conditions, businesses can protect their assets and prolong the lifespan of their docking facilities. Investing in custom fender seals is not merely a matter of preference; it is a strategic decision that contributes to the long-term sustainability and viability of maritime operations. With the right customization, marine fender seals can offer unparalleled protection, making them an indispensable component of modern maritime safety.

Next: