Dec . 14, 2024 04:50 Back to list

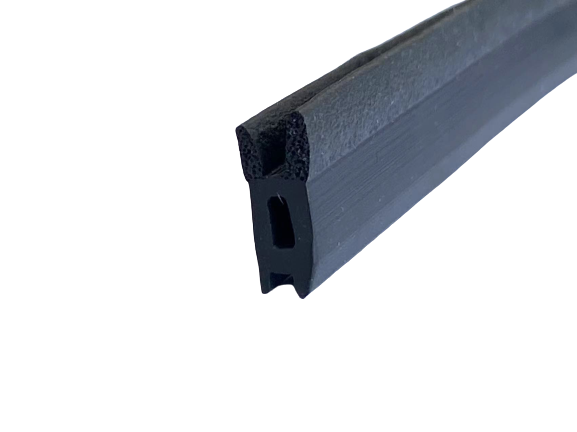

High-Quality Neoprene Foam Rubber Sheets for Versatile Applications and Durability

Understanding Neoprene Foam Rubber Sheets A Versatile Material for Various Applications

Neoprene foam rubber sheets have gained significant popularity in various industries due to their exceptional properties and versatility. This synthetic rubber material, developed in the 1930s, offers incredible resistance to heat, weather, and chemicals, making it an essential component in several applications, from industrial uses to consumer products. In this article, we will explore the characteristics of neoprene foam rubber sheets, their benefits, and the diverse applications where they are commonly used.

What is Neoprene Foam Rubber?

Neoprene, also known as polychloroprene, is a type of synthetic rubber that is created through the polymerization of chloroprene. When combined with foam, it results in a material that possesses outstanding durability and flexibility. The foam structure of neoprene rubber sheets allows for excellent insulation properties, making them an ideal choice for applications requiring thermal regulation and cushioning.

Key Characteristics of Neoprene Foam Rubber Sheets

1. Chemical Resistance Neoprene has remarkable resistance to a wide range of chemicals, including oils, greases, and solvents. This feature makes it suitable for use in environments where exposure to such substances is commonplace.

2. Weather Resistance The material can withstand extreme weather conditions, including sun exposure, rain, and humidity. This quality makes neoprene foam rubber sheets particularly useful in outdoor applications or locations with fluctuating temperatures.

3. Flexible and Stretchable Neoprene is inherently flexible, which allows it to be used in products that require movement, such as body-protective gear and insulation applications.

4. Excellent Thermal Insulation Neoprene foam sheets provide effective thermal insulation, making them popular in applications requiring temperature regulation.

5. Sound Absorption The foam structure of neoprene enhances sound-dampening properties, providing an effective barrier against noise.

6. Compressibility These sheets can be easily compressed and return to their original shape, making them suitable for cushioning applications.

Benefits of Neoprene Foam Rubber Sheets

The unique properties of neoprene foam rubber sheets offer numerous advantages for specific applications

neoprene foam rubber sheet

- Durability The long-lasting nature of neoprene makes it an economical choice for many industries, as products made from this material do not require frequent replacement.

- Safety Neoprene does not support the growth of mold, bacteria, or fungi, ensuring a safer environment in applications like medical products.

- Versatility Available in various thicknesses and densities, neoprene foam sheets can be tailored to meet specific needs for different products.

- Ease of Processing Neoprene can be cut, glued, and shaped easily, which simplifies the manufacturing process for end products.

Applications of Neoprene Foam Rubber Sheets

1. Industrial Use Neoprene foam sheets are widely used in the automotive and aerospace industries for gaskets, seals, and insulation components. Their chemical resistance is crucial for ensuring the longevity of these parts.

2. Consumer Goods Many sporting goods, such as knee pads, wrist braces, and wetsuits, are made from neoprene foam due to its flexible and insulating properties. Additionally, neoprene is often used in laptop sleeves and cases for its protective capabilities.

3. Construction In the construction field, neoprene sheets are used for roofing, providing waterproofing and insulation benefits, as well as in flooring products for sound deadening.

4. Medical Applications Many medical supplies, such as orthopedic braces, use neoprene foam for its ability to provide support and compression while remaining comfortable against the skin.

5. Marine Applications Neoprene is popular in marine environments for manufacturing products like life jackets and wetsuits due to its water resistance and thermal properties.

Conclusion

Neoprene foam rubber sheets stand out as an important material across numerous industries. Their unique combination of flexibility, durability, weather resistance, and insulation properties make them a perfect fit for a wide variety of applications. As industries continue to evolve, the demand for such versatile materials is likely to increase, solidifying neoprene foam rubber sheets' place as a cornerstone in both industrial manufacturing and consumer product design. Whether in automobiles, sports gear, or medical equipment, neoprene continues to demonstrate its worth as a reliable material solution.