Nov . 11, 2024 05:41 Back to list

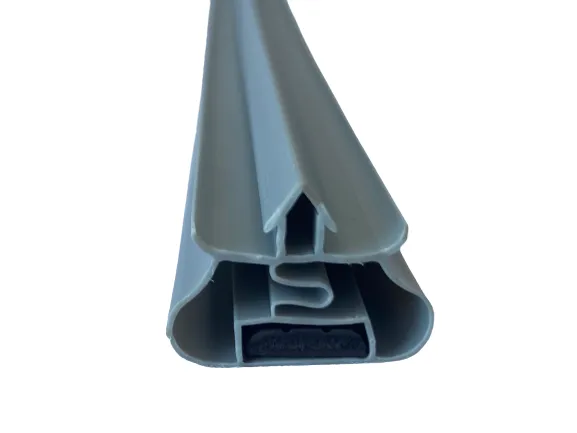

Customizable ODM Marine Fender Seals for Various Applications and Specifications

Customizable ODM Marine Fender Seals Ensuring Safety and Reliability for Marine Applications

In the ever-evolving marine industry, safety and precision are paramount. One critical component that significantly contributes to marine safety is the marine fender seal. These durable structures protect vessels during docking and berthing, absorbing the energy of the impact and preventing damage to both the vessel and the dock. With the increasing demand for specialized marine solutions, customizable Ocean Dynamic Marine (ODM) fender seals have emerged as a preferred choice for many operators in the maritime sector.

Marine fender seals are designed to cushion the impact between a ship and the berth. They play an essential role in minimizing the risk of damage to both ships and docks. ODM offers a range of customizable solutions that cater to the diverse requirements of different marine applications. This customization ensures that every client can obtain fender seals tailored to their specific needs, taking into account factors such as vessel size, berth structure, and environmental conditions.

One of the main advantages of ODM marine fender seals is their flexibility in design. Depending on the nature of the marine environment, it is possible to modify the size, shape, and material of the fender seals to ensure optimal performance. For instance, harsher climates may require materials with enhanced durability and resistance to abrasion, while smaller vessels may benefit from compact fender designs that ensure efficient use of space without compromising safety.

Moreover, the customization option allows for the integration of advanced features that can further enhance the functionality of marine fender seals. For example, the incorporation of reflective surfaces can improve visibility at night or in low-light conditions, aiding in safe maneuvering. Additionally, ODM can equip fender seals with built-in sensors that monitor wear and tear, providing real-time data to operators and allowing for proactive maintenance.

odm marine fender seals can be customized

The manufacturing process of ODM marine fender seals employs cutting-edge technology and adheres to stringent quality control measures. Each product undergoes rigorous testing to ensure it meets industry standards while maintaining the flexibility needed for customization. This not only guarantees the reliability of the marine fender seals but also fosters confidence among operators who rely on these critical components for the safety of their vessels.

Furthermore, the availability of customizable solutions underscores ODM's commitment to understanding and responding to client needs. By working closely with customers, ODM can develop fender seals that not only meet technical specifications but also align with the economic goals of the vessel operators. This collaborative approach ensures that solutions are sustainable and cost-effective, making it a win-win for all parties involved.

As the maritime industry continues to grow, so does the complexity of the environments in which vessels operate. In this context, the demand for customizable marine fender seals is expected to rise. Operators are looking for solutions that can adapt to their unique requirements, enhancing safety while minimizing operational disruptions. ODM stands at the forefront of this trend, ready to provide bespoke solutions that combine innovation with practicality.

In conclusion, ODM marine fender seals represent a significant advancement in the field of marine safety solutions. Their customizable nature, combined with robust manufacturing processes and advanced features, makes them an ideal choice for operators seeking reliability and efficiency in marine operations. By choosing ODM, companies can ensure that their vessels are equipped with the best protective measures, safeguarding investments and ensuring safe engagements in various maritime environments. With customizable marine fender seals, the future of maritime safety looks promising.