Nov . 24, 2024 18:59 Back to list

High-Performance EPDM Rubber Sheets for Diverse Industrial Applications

Understanding EPDM Rubber Sheets Properties and Applications

EPDM (Ethylene Propylene Diene Monomer) rubber sheets have become increasingly popular across various industries due to their unique properties and versatility. This synthetic rubber is characterized by excellent resistance to temperature fluctuations, ozone, UV radiation, and aging, making it an ideal choice for outdoor applications.

Composition and Physical Properties

EPDM is made from a combination of ethylene, propylene, and a diene component, which contributes to its elasticity and strength. The material's molecular structure provides it with excellent tensile strength and flexibility, enabling it to withstand dynamic loads and maintain its shape over time. EPDM rubber sheets typically come in a variety of thicknesses and widths, making them suitable for a range of applications.

One of the standout features of EPDM rubber is its ability to perform well in extreme weather conditions. It can endure temperatures as low as -40°F (-40°C) and as high as 250°F (121°C), which is crucial for applications that require durability in both hot and cold climates. Additionally, its resistance to UV rays and ozone means that EPDM sheets will not degrade or lose their mechanical properties when exposed to sunlight, making them an excellent option for outdoor use.

Applications

Understanding EPDM Rubber Sheets Properties and Applications

1. Roofing EPDM roofing systems are widely used in commercial and residential buildings. The material's weather resistance and longevity make it an efficient choice for flat or low-sloped roofs, helping to prevent leaks and water damage.

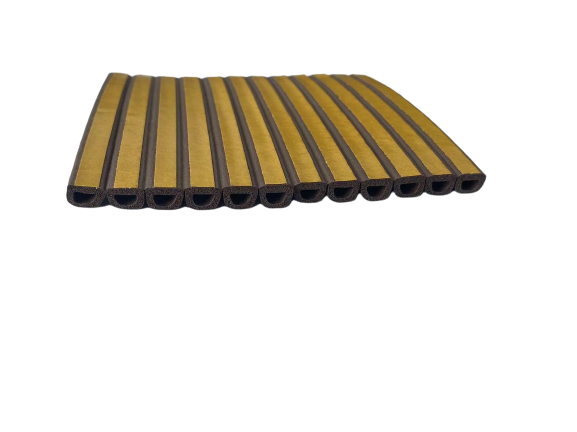

rubber epdm sheet

2. Automotive Components EPDM rubber is often used in automotive weather stripping, seals, and gaskets. Its ability to withstand temperature extremes and chemical exposure allows it to maintain effective sealing properties over time, ensuring vehicle longevity and efficiency.

3. Industrial Uses EPDM sheets are used in various industrial applications, including conveyor belts, protective coverings, and vibration dampening. Their strength and resilience make them suitable for high-impact environments.

4. HVAC Systems The insulating properties of EPDM are beneficial in HVAC systems, helping to reduce energy loss and improve efficiency. EPDM sheets can also be employed as liners and seals within air conditioning units and ductwork.

5. Electrical Insulation The high dielectric strength of EPDM makes it an excellent choice for electrical insulation applications, protecting components against moisture and environmental factors.

Installation and Maintenance

Installing EPDM rubber sheets typically involves adhesive bonding, mechanical fastening, or both. The seams must be appropriately handled to ensure a watertight seal, especially in roofing applications. Regular maintenance, such as cleaning and inspection for wear and tear, will help extend the life of EPDM products and maintain their performance.

Conclusion

In summary, EPDM rubber sheets are an exceptional material choice for a wide range of applications due to their superior weather resistance, flexibility, and durability. Whether in roofing, automotive parts, or industrial settings, the properties of EPDM make it a reliable option for engineers and designers seeking long-lasting solutions. As industries continue to look for materials that can withstand environmental challenges, EPDM rubber sheets remain a frontrunner in providing effective and efficient results.