Dec . 14, 2024 14:48 Back to list

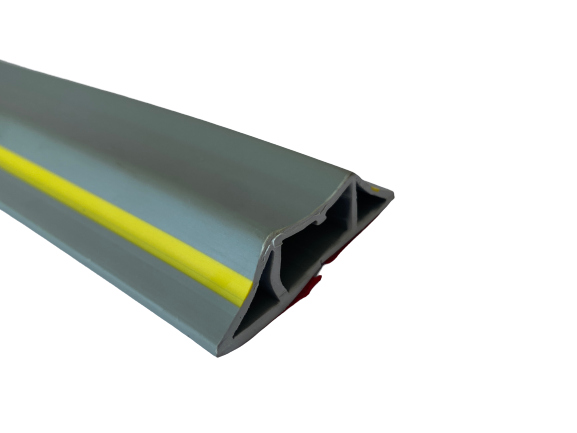

rubber seals for plastic steel doors and windows factory

Understanding Rubber Seals for Plastic and Steel Doors and Windows

In the modern construction and manufacturing industry, the focus on energy efficiency and durability has led to a surge in the use of rubber seals in various applications. Particularly, rubber seals have become essential components for plastic and steel doors and windows. This article explores the significance, types, and benefits of rubber seals, the materials used in their production, and their role in enhancing the functionality and longevity of entryways and fenestration systems.

The Importance of Rubber Seals

Rubber seals serve as a barrier against environmental elements, ensuring that indoor spaces remain insulated from external conditions. They prevent air leaks, moisture intrusion, and dust, significantly improving energy efficiency within buildings. With rising energy costs and increased emphasis on sustainability, the role of rubber seals is more critical than ever.

In doors and windows, rubber seals are engineered to provide a tight fit, minimizing gaps that can lead to drafts and energy loss. This not only helps in maintaining a comfortable indoor temperature but also reduces the workload on heating, ventilation, and air conditioning (HVAC) systems. Consequently, buildings equipped with effective sealing systems can experience substantial energy savings over time.

Types of Rubber Seals

There are several types of rubber seals used for plastic and steel doors and windows, each designed for specific applications

1. Gasket Seals Often used around windows and doors, these seals are designed to compress and fill gaps when the door or window is closed, ensuring a secure fit.

2. Weatherstripping This flexible material can be applied to the edges of doors and windows, providing an additional layer of protection against the elements.

3. EPDM Seals Ethylene Propylene Diene Monomer (EPDM) rubber is common for those applications that require high durability and resistance to UV rays, ozone, and temperature extremes.

4. Silicone Seals These seals offer excellent flexibility and resistance to extreme temperatures, making them suitable for high-performance windows and doors.

5. PVC Seals While not rubber, PVC seals are utilized for their cost-effectiveness and resistance to certain environmental factors, thereby extending the lifespan of plastic doors and windows.

Materials Used in Rubber Seal Production

rubber seals for plastic steel doors and windows factory

The manufacturing of rubber seals often involves various synthetic and natural rubber compounds. Common materials include neoprene, nitrile, and silicone, each presenting unique properties that dictate their suitability for specific applications.

- Neoprene is known for its excellent resilience and durability, making it ideal for weatherproofing applications. - Nitrile Rubber is praised for its resistance to oils and fuels, making it suitable for industrial applications in doors and windows used in such environments.

- Silicone Rubber offers high-performance attributes in extreme temperatures and is often utilized in climates with significant temperature variations.

The Benefits of Using Rubber Seals

Using rubber seals in plastic and steel doors and windows comes with numerous advantages

1. Energy Efficiency By reducing air leaks and preventing temperature fluctuations, rubber seals can lower energy bills significantly.

2. Improved Comfort A well-sealed door or window maintains a consistent indoor climate, enhancing the comfort of occupants.

3. Noise Reduction Rubber seals can effectively dampen sound, contributing to quieter indoor environments, particularly in urban areas.

4. Extended Lifespan of Doors and Windows By preventing moisture intrusion, rubber seals help reduce the risk of rot and degradation, thus prolonging the life of both plastic and steel frames.

5. Cost-Effectiveness The initial investment in quality rubber seals is offset by long-term savings in energy costs and property maintenance.

Conclusion

In conclusion, rubber seals are indispensable components in the construction and design of plastic and steel doors and windows. They provide critical benefits that enhance the energy efficiency, comfort, and durability of buildings. As the demand for energy-efficient solutions continues to grow, the importance of rubber seals will likely increase, leading to ongoing innovation in their design and application. For manufacturers and builders, investing in high-quality rubber seals is not just a recommendation; it is an essential strategy for meeting contemporary construction standards and homeowner expectations.

Next:

Prev: