Dec . 19, 2024 19:01 Back to list

sealing strip for gaps in photovoltaic solar panels factories

Sealing Strips for Gaps in Photovoltaic Solar Panels Enhancing Efficiency and Longevity

In recent years, the renewable energy sector has witnessed a remarkable surge in popularity, with photovoltaic (PV) solar panels leading the charge. As countries strive to harness solar energy to meet growing energy demands and combat climate change, the need for reliable and efficient solar panel manufacturing has never been more pressing. One crucial aspect of this production process is the implementation of sealing strips for gaps in photovoltaic solar panels. These seemingly minor components play a significant role in ensuring the longevity and efficiency of solar energy systems.

Understanding the Need for Sealing Strips

Photovoltaic solar panels are comprised of multiple layers designed to capture and convert sunlight into electricity. However, during manufacturing and installation, small gaps may occur between these layers or the junctions of solar panels, which can lead to significant issues if left unaddressed. Unsealed gaps can allow moisture, dust, and debris to enter, posing threats to the integrity and performance of the solar panels. Over time, such intrusions can cause corrosion, mechanical failures, and reduced energy output.

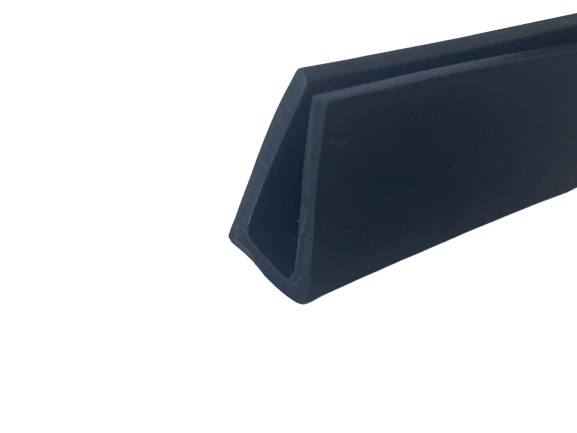

Sealing strips are designed to fill these gaps effectively, creating a barrier that protects the inner components from environmental factors. Made from materials that can withstand exposure to UV light, extreme temperatures, and moisture, these sealing strips are essential in maintaining the performance and durability of solar panels.

Types of Sealing Strips Used

The market offers a variety of sealing strips tailored for different types of photovoltaic panels and environmental conditions. Common materials include silicone, EPDM (ethylene propylene diene monomer), and polyurethane. Each of these materials has unique properties suited for specific applications

1. Silicone Sealing Strips Known for their flexibility and resistance to extreme temperatures, silicone sealing strips are ideal for areas prone to thermal expansion and contraction. They provide excellent adhesion and can maintain performance over a wide temperature range.

2. EPDM Sealing Strips EPDM is favored for its durability and resistance to UV rays and weathering. This material is particularly effective in outdoor applications, where exposure to the elements is inevitable.

sealing strip for gaps in photovoltaic solar panels factories

3. Polyurethane Sealing Strips Offering high elasticity and tensile strength, polyurethane strips can withstand significant wear and tear. They are often used in demanding environments where mechanical stress is a concern.

Benefits of Using Sealing Strips

Incorporating sealing strips into photovoltaic solar panel manufacturing and installation can lead to numerous benefits

1. Enhanced Efficiency By preventing the ingress of moisture and debris, sealing strips help maintain the optimal working condition of solar panels, ensuring that they operate at peak efficiency. This translates to higher energy output and better return on investment.

2. Increased Lifespan Sealing strips protect the internal components of solar panels from damage caused by environmental factors. This protection significantly extends the lifespan of the solar energy system, reducing the need for premature replacements.

3. Cost-Effectiveness While the initial investment in sealing strips may be seen as an added expense, the long-term savings associated with increased efficiency and reduced maintenance costs far outweigh this cost.

4. Environmental Protection By helping to prevent degradation, sealing strips contribute to the sustainability of solar panels. Longer-lasting solar panels reduce waste and the demand for new materials, promoting a more sustainable approach to energy production.

Conclusion

The role of sealing strips in photovoltaic solar panels cannot be overstated. As the demand for solar energy continues to grow, manufacturers must prioritize the incorporation of high-quality sealing solutions to protect the integrity, efficiency, and durability of solar panels. By addressing gaps effectively, sealing strips not only enhance the performance of individual solar installations but also contribute to the overarching goal of a sustainable energy future. As technology evolves, we expect further innovations in sealing materials and techniques, which will continue to bolster the renewable energy sector and help pave the way for a greener tomorrow.