Dec . 07, 2024 11:32 Back to list

shipping container door rubber seals

Understanding Shipping Container Door Rubber Seals Importance, Types, and Maintenance

Shipping containers have revolutionized global trade, providing a robust and efficient means of transporting goods across oceans and continents. One critical component of these containers is the door rubber seals, an often-overlooked feature that plays a vital role in maintaining the integrity of the cargo. This article delves into the importance of these seals, the various types available, and best practices for maintenance.

Importance of Door Rubber Seals

The primary function of shipping container door rubber seals is to ensure that the doors of the container close tightly. This tight seal is crucial for several reasons

1. Protection Against Elements Shipping containers are often exposed to harsh environmental conditions, including rain, wind, and extreme temperatures. Rubber seals prevent water from leaking into the container, protecting the cargo from moisture damage and corrosion.

2. Security A tight seal also helps secure the contents of the container. This minimization of gaps not only deters theft but also prevents unauthorized access, ensuring that the goods inside remain safe throughout their journey.

3. Temperature Control For temperature-sensitive cargo, maintaining a stable environment is essential. Rubber seals help in insulating the container, reducing the fluctuation in temperature and keeping the goods in optimal condition.

4. Air Quality Maintenance Certain products, such as food and pharmaceuticals, require specific air quality standards. Seals help maintain the internal atmosphere of the container, preventing contamination and preserving the quality of the goods.

Types of Rubber Seals

Shipping container door rubber seals come in various types, each designed for specific applications and requirements

1. Flat Seals These are the most common type of rubber seals, designed to fit into the grooves around the container doors. They provide a straightforward and efficient sealing solution that is both durable and reliable.

shipping container door rubber seals

2. D-shaped Seals Shaped like the letter D, these seals offer a larger surface area for better compression against the door frames. This design is especially useful for containers requiring enhanced weatherproofing.

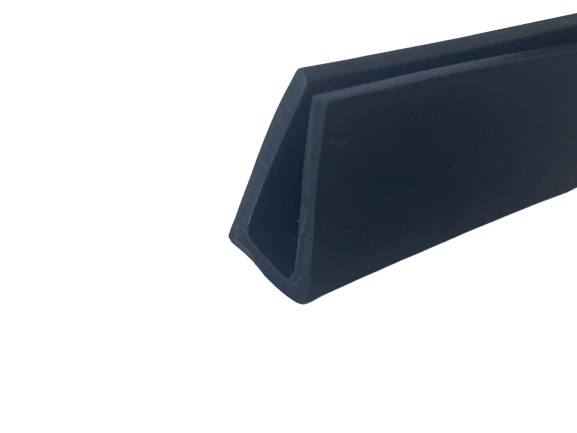

3. U-shaped Seals Similar to D-shaped seals, the U-shape allows for a significant amount of compression, providing excellent protection against leaks and enhancing security.

4. Custom-Made Seals For specialized containers or those with unique requirements, custom-made rubber seals can be manufactured. These seals can be tailored to fit specific dimensions and conditions, ensuring maximum effectiveness.

Maintenance of Door Rubber Seals

Maintaining rubber seals is essential for ensuring their longevity and effectiveness. Here are some tips for proper maintenance

1. Regular Inspections Regularly check the seals for signs of wear, such as cracks, tears, or deformities. Early detection of damage can prevent larger issues down the road.

2. Cleaning Keep the seals clean and free from dirt and debris, as buildup can compromise their sealing ability. Use mild soap and water for cleaning; avoid harsh chemicals that could degrade the rubber.

3. Lubrication Applying a silicone-based lubricant can help maintain the flexibility of rubber seals, preventing cracking and drying out, especially in extreme weather conditions.

4. Replacement Over time, even the best-maintained rubber seals will wear out. Be prepared to replace seals at regular intervals or as soon as significant damage is observed to ensure continued protection for your cargo.

Conclusion

Shipping container door rubber seals might seem like small components, but they play a vital role in safeguarding the integrity of cargo during transport. Understanding their importance, recognizing the different types, and implementing effective maintenance practices can enhance the performance and longevity of these seals. By ensuring that rubber seals are in optimal condition, shippers can protect their goods against the elements, maintain security, and uphold the quality of their products throughout the transport journey.