Dec . 01, 2024 18:28 Back to list

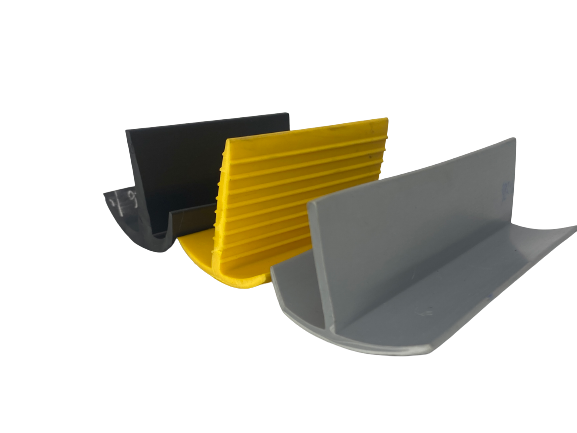

tank strap rubber

The Versatile World of Tank Strap Rubber A Comprehensive Overview

In the realm of industrial and automotive applications, tank strap rubber plays a pivotal role that often goes unnoticed. This essential component serves as a high-performance material designed to provide durability, flexibility, and resilience in various environments. A tank strap typically secures large containers such as fuel tanks, coolant tanks, and hydraulic tanks in vehicles and machinery. In this article, we will delve into the importance, applications, and benefits of tank strap rubber.

Understanding Tank Strap Rubber

Tank strap rubber is a specialized material made from synthetic or natural rubber composites. These materials are tailored to withstand harsh conditions, including extreme temperatures, vibrations, and exposure to various chemicals. The composition of tank strap rubber typically includes a mix of natural rubber, neoprene, and other protective additives to enhance performance and longevity.

One of the core functions of tank strap rubber is to provide a cushion between the tank and its mounting surface. This cushioning effect not only minimizes movement and potential damage during operation but also absorbs shock and reduces noise, making it crucial for vehicles and equipment in motion.

Applications of Tank Strap Rubber

The versatility of tank strap rubber allows it to be employed across a wide range of industries

1. Automotive Sector In the automotive industry, tank strap rubber is extensively used in securing fuel tanks and coolant reservoirs. The properties of the rubber ensure that these critical components remain stable, secure, and protected from environmental factors that could lead to leaks or failures.

2. Industrial Equipment Many types of industrial equipment rely on tank strap rubber for securing hydraulic fluid tanks and lubrication tanks. The resilient nature of the rubber helps accommodate the vibrations and movements associated with machinery, preventing undue wear and tear.

3. Marine Applications Boats and ships use tank strap rubber to secure various fluid tanks, including fuel and water tanks. Given the marine environment's exposure to saltwater and moisture, using high-quality rubber that resists corrosion and degradation is vital.

tank strap rubber

4. Agricultural Machinery Farm equipment, such as tractors and harvesters, depend on tank strap rubber to secure fluid tanks in place, ensuring efficiency and safety during operations that often involve bumpy terrains.

Benefits of Using Tank Strap Rubber

1. Durability The primary advantage of tank strap rubber is its ability to withstand harsh operating conditions. It is designed to endure temperature changes, chemical exposure, and physical stress, which translates to a longer lifespan for both the strap and the tank it secures.

2. Flexibility The inherent flexibility of rubber allows tank straps to adjust to the tank's shape and positioning without compromising the security of the installation. This flexibility is essential for applications where equipment must move but remain safely anchored.

3. Shock Absorption Effective shock absorption minimizes the impact of unexpected bumps and jolts on the tank and its mounted system. This capability is crucial in maintaining the integrity of both the tank and the fluid it contains.

4. Cost-Effectiveness While investing in high-quality tank strap rubber may seem costly initially, its durability and performance contribute to reduced maintenance costs and fewer replacements in the long run. A reliable tank strap can protect valuable components from damage, preventing costly repairs or replacements.

5. Safety Ensuring that tanks are securely fastened with reliable materials like rubber enhances overall safety in operations, particularly in vehicles and machinery that handle flammable or hazardous substances.

Conclusion

Tank strap rubber might not be the most glamorous component in automotive or industrial design, but its importance cannot be overstated. Providing security, protection, and durability, it plays a vital role in ensuring the effective operation of various systems. Understanding the material’s applications and benefits can lead to better choices in manufacturing and maintenance, ultimately contributing to enhanced efficiency and safety across multiple industries. As technology advances, the development of even more robust and specialized rubber compositions is likely to evolve, meeting the ever-increasing demands of modern applications.