Jan . 20, 2025 14:20 Back to list

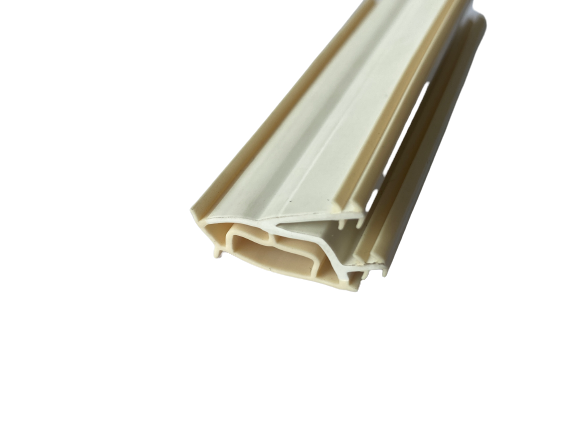

L-shapedanti-skid PVCrubberstrip staircase opening

The quest for the best EPDM automotive fuel tank gasket often leads discerning customers through a maze of technical specifications and industry claims, making the choice both critical and complex. EPDM, or Ethylene Propylene Diene Monomer, represents one of the most versatile and durable synthetic rubbers available today, particularly in automotive applications.

Experience from both the automotive industry and individual consumers shines a light on the significance of precision engineering in EPDM gaskets. The craftsmanship behind these products balances material flexibility with mechanical strength, ensuring they can endure the internal pressures of a fuel tank without compromising their sealing capabilities. Automotive engineers advocate for EPDM due to its ability to be custom-molded, allowing designers to replicate exact specifications required for each vehicle model, achieving optimal performance. In a marketplace flooded with options, the credibility of an EPDM gasket manufacturer is supported by certifications and adherence to stringent industry standards. Look for products meeting ISO/TS 16949 standards, a testament to quality management in the automotive supply chain, and confirming the gasket’s premium quality. Trustworthy vendors will offer warranties or guarantees, further underlining their confidence in the product’s longevity and performance. Conclusively, when seeking the best EPDM automotive fuel tank gasket, prioritize those with a proven track record of reliability and compliance with industry standards. This careful selection not only enhances vehicle efficiency but also ensures safety, providing peace of mind with every drive. Equip your vehicle with gaskets that industry experts trust, and experience firsthand the advantages of superior material technology. Embrace the power of EPDM and enjoy the assurances of a well-sealed, meticulously engineered automotive solution.

Experience from both the automotive industry and individual consumers shines a light on the significance of precision engineering in EPDM gaskets. The craftsmanship behind these products balances material flexibility with mechanical strength, ensuring they can endure the internal pressures of a fuel tank without compromising their sealing capabilities. Automotive engineers advocate for EPDM due to its ability to be custom-molded, allowing designers to replicate exact specifications required for each vehicle model, achieving optimal performance. In a marketplace flooded with options, the credibility of an EPDM gasket manufacturer is supported by certifications and adherence to stringent industry standards. Look for products meeting ISO/TS 16949 standards, a testament to quality management in the automotive supply chain, and confirming the gasket’s premium quality. Trustworthy vendors will offer warranties or guarantees, further underlining their confidence in the product’s longevity and performance. Conclusively, when seeking the best EPDM automotive fuel tank gasket, prioritize those with a proven track record of reliability and compliance with industry standards. This careful selection not only enhances vehicle efficiency but also ensures safety, providing peace of mind with every drive. Equip your vehicle with gaskets that industry experts trust, and experience firsthand the advantages of superior material technology. Embrace the power of EPDM and enjoy the assurances of a well-sealed, meticulously engineered automotive solution.