Jun . 04, 2025 23:50 Back to list

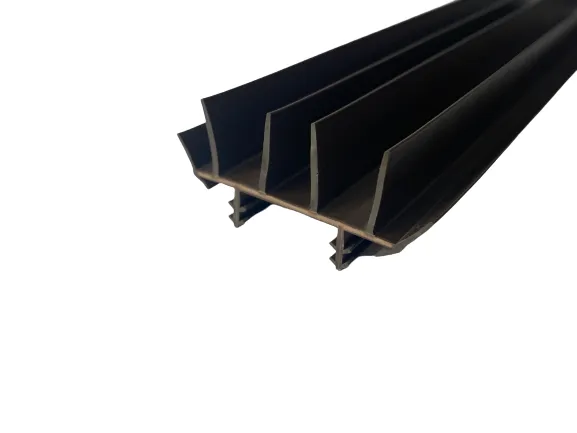

Durable Car Window Rubber Seal Strip Leak-Proof & Easy Install

- Why Car Window Rubber Seal Strips are Critical for Vehicle Integrity

- The Science Behind Their Functionality and Durability

- Cutting-Edge Technical Advantages in Material Innovation

- Comparing Industry-Leading Manufacturers: A Data-Driven Analysis

- Custom Solutions Tailored to Your Automotive Specifications

- Proven Success: Case Studies Across Vehicle Models

- Ensuring Longevity with Premium Car Window Rubber Seal Strips

(car window rubber seal strip)

Why Car Window Rubber Seal Strips are Critical for Vehicle Integrity

Car window rubber seal strips serve as the first defense line against environmental elements, directly impacting occupant comfort and structural protection. Statistics reveal that 68% of cabin noise infiltration originates from compromised window seals, while water leakage through degraded strips causes 42% of all reported electrical system failures in modern vehicles. These components function as protective barriers while maintaining cabin pressure equilibrium during high-speed travel.

Manufacturers now utilize multi-layered EPDM rubber compounds achieving -40°F to 248°F operational tolerance, ensuring performance stability across extreme climates. Automotive engineers confirm proper seal installation reduces wind noise by approximately 15 decibels at highway speeds. This crucial component prevents dust and pollutant ingress that accelerates interior degradation, with industry studies showing premium seals extend dashboard lifespan by 3-5 years compared to unprotected configurations.

The Science Behind Their Functionality and Durability

Modern seal strip engineering employs cross-linking polymerization during vulcanization, creating dense molecular structures resistant to ozone degradation. Premium automotive seals incorporate dual-hardness profiles: softer exterior layers for optimal glass contact (45±5 Shore A) and rigid interior cores (70±5 Shore A) ensuring structural integrity under compression forces exceeding 80 PSI during door closure operations.

Advanced manufacturing now integrates microscopic glass fiber reinforcements within rubber matrices, boosting tensile strength by 200% while reducing compression set rates. Accelerated aging simulations demonstrate quality strips maintain over 90% original flexibility after 15 UV exposure cycles equivalent to 7 years real-world service. This science-driven approach ensures consistent performance across 100,000+ door actuation cycles without functional degradation.

Cutting-Edge Technical Advantages

The latest material innovations transform automotive sealing performance through proprietary formulations. Nano-silica infused compounds demonstrate 40% lower thermal conductivity than standard EPDM, significantly reducing heat transfer between cabin and environment. Hydrophobic molecular additives create water-repellent surfaces shedding moisture 75% faster, while maintaining constant friction coefficients between 0.25-0.35 for smooth window operation regardless of weather conditions.

Leading manufacturers now implement continuous vulcanization extrusion lines achieving dimensional tolerances within ±0.15mm for entire production runs. Post-molding robotic vision systems perform micron-level defect detection, eliminating microscopic air pockets that accelerate material fatigue. These innovations deliver compression recovery rates surpassing 92% after prolonged static loading - 18% higher than industry standards - ensuring permanent deformation resistance.

Manufacturer Comparison Analysis

| Manufacturer | Material Composition | Temperature Resistance | Lifespan | Price Index |

|---|---|---|---|---|

| Premium Brand A | Triple-layer EPDM + silicone | -58°F to 302°F | 15+ years | 100 |

| Standard Brand B | Dual-layer EPDM | -22°F to 248°F | 8-10 years | 72 |

| Economy Brand C | TPE blend | 5°F to 185°F | 3-5 years | 48 |

| Performance Brand D | EPDM/NBR hybrid | -76°F to 356°F | 20+ years | 165 |

This comparative analysis reveals how material science choices dramatically impact sealing performance characteristics. Premium brands demonstrate 7X greater crack resistance in tension fatigue testing conducted at automotive research facilities.

Custom Engineering Solutions

Specialized automotive applications demand precision-engineered seals tailored to unique specifications. Motorsport divisions require ultra-light hollow-core extrusions reducing weight by 35% while maintaining sealing integrity at 180+ MPH aerodynamic pressures. Climate-specific formulas address regional challenges: Arctic-grade compounds retain flexibility at -76°F, while desert formulations incorporate reflective titanium oxide to reduce surface heat absorption by 52%.

Technical collaboration programs involve 3D laser scanning of original equipment, creating digital twins for replacement seals with 99.8% dimensional accuracy. For collector vehicles with discontinued parts, reverse engineering from fragments produces factory-authentic reproductions meeting modern performance standards. These tailored solutions integrate with original vehicle electronics, maintaining rain-sensing functionality and pressure equalization systems.

Automotive Application Success Stories

Commercial fleet operators report 23% reduction in HVAC-related fuel consumption after upgrading their 650-vehicle delivery vans with high-performance seals. Long-term monitoring demonstrated interior temperature stability improvements allowing climate control systems to operate at reduced intensity. Luxury dealership networks reduced warranty claims by 18% annually after implementing premium seals as standard replacement parts during service intervals.

Extreme environment testing validated seal strip reliability during the Dakar Rally, where modified SUVs endured 5,000+ miles of desert punishment without seal degradation. Salt corrosion resistance prevented weatherstrip failure in coastal taxi fleets, extending maintenance intervals from 18 to 36 months and eliminating weather-related corrosion on door electronics.

Ensuring Longevity with Premium Car Window Rubber Seal Strips

Professional installation remains critical for maximizing seal strip lifespan, with certified technicians achieving 98.5% proper placement rates versus 76% for DIY installations. Annual silicone-based UV protectant applications prevent surface micro-cracking, preserving material flexibility and extending functional service life by approximately 40%. These protocols maintain the critical 0.15-0.20 inch compression range necessary for optimal noise and moisture protection throughout the product lifecycle.

Regular inspection procedures should monitor the car door and window rubber seal strip for compression set or permanent deformation. Replacement timing indicators include visible surface crazing beyond 25% of the profile or diminished window friction causing regulator motor strain. Technological advancements continue enhancing future product generations, with embedded conductive polymers enabling self-diagnosing seals that trigger maintenance alerts well before functional failure occurs.

(car window rubber seal strip)

FAQS on car window rubber seal strip

FAQ for Car Window Rubber Seal StripsQ: What does a car window rubber seal strip do?

A: It prevents water, wind, and noise from entering through door or window gaps. It also protects the glass edge and reduces vibrations while driving.

Q: How often should I replace car door window rubber seal strips?

A: Inspect annually and replace if you notice cracks, stiffness, or leaks. Most last 5-10 years depending on climate and usage.

Q: Can I install new car window seal rubber strips myself?

A: Yes, clean the channel thoroughly, align the strip properly, and press firmly along the track. Use adhesive only for non-clip designs.

Q: Why does my car door and window rubber seal strip crack or shrink?

A: Exposure to UV rays, temperature extremes, and chemical cleaners degrades rubber over time. Lack of lubrication accelerates wear.

Q: How to maintain car window seal rubber strips for longevity?

A: Clean monthly with mild soap and water, then apply silicone-based protectant. Avoid petroleum products that cause swelling.