Nov . 23, 2024 16:10 Back to list

famous anti-collision rubber seal for ship type d

The Importance of Anti-Collision Rubber Seals for Ships A Focus on Type D

In the maritime industry, safety and efficiency are paramount. One of the critical components that contribute to the safety of vessels is the anti-collision rubber seal, specifically the Type D design. These seals play a pivotal role in protecting ships from impacts, thus ensuring the integrity of both the vessel and the cargo it carries.

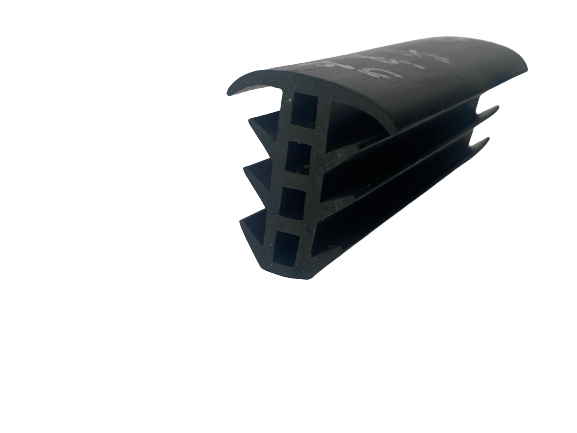

Anti-collision rubber seals are designed to absorb and dissipate the energy generated during a collision, reducing the risk of structural damage to the ship. The Type D seal is particularly renowned for its robustness and effectiveness. Made from high-quality rubber compounds, these seals are engineered to withstand the harsh marine environment, including extreme temperatures, saltwater exposure, and UV radiation. This durability ensures that they maintain their performance over time, safeguarding vessels from potential damage.

The design of Type D anti-collision seals features a unique configuration that allows for optimal impact absorption. They are often installed along the hull of the ship or around protruding parts like fenders and loading bays. The ability of these seals to deform upon impact helps in minimizing the force transmitted to the structure of the ship, thereby protecting critical components from damage. This is especially crucial in busy ports where the risk of collision with other vessels or dock structures is heightened.

In addition to physical protection, Type D anti-collision seals also contribute to operational efficiency. By reducing the likelihood of damage during docking and mooring operations, vessels can maintain tighter schedules and avoid costly delays associated with repairs. This efficiency is vital in a fiercely competitive industry where timely deliveries are essential for customer satisfaction and profitability.

famous anti-collision rubber seal for ship type d

Moreover, implementing high-quality anti-collision seals can lead to long-term cost savings for shipping companies. While the initial investment in quality Type D seals may be higher than subpar alternatives, the reduced risk of damage and maintenance provides a significant return on investment. Companies can also benefit from lower insurance premiums due to the enhanced safety measures these seals provide.

The adoption of Type D anti-collision rubber seals is not merely a best practice; it is becoming a standard requirement in the design and maintenance of modern vessels. With stricter safety regulations and heightened environmental awareness, the use of advanced sealing solutions reflects the industry's commitment to safety and sustainability.

As the maritime industry continues to evolve, so does the technology behind anti-collision seals. Manufacturers are continually researching and developing new materials and designs to enhance the performance of these essential components. Innovations in this field promise to lead to even safer and more efficient maritime operations in the future.

In conclusion, the Type D anti-collision rubber seal serves as a vital protective measure for vessels, playing an indispensable role in ensuring maritime safety. Its combination of durability, efficiency, and cost-effectiveness makes it a preferred choice for shipbuilders and operators worldwide. As the industry faces ongoing challenges related to safety and efficiency, the importance of high-quality anti-collision solutions like the Type D seal cannot be understated.