Apr . 29, 2025 15:40 Back to list

High-Quality Marine Fender Sealing Strips Durable & Waterproof Solutions

- Overview of Marine Fender Sealing Solutions

- Technical Advantages in Design and Material

- Performance Comparison of Leading Manufacturers

- Customization Options for Diverse Applications

- Case Studies: Real-World Implementations

- Industry Standards and Compliance Metrics

- Future Trends in Marine Fender Sealing Technology

(marine fender sealing strip)

Optimizing Port Safety with Marine Fender Sealing Strip Solutions

Marine fender sealing strips serve as critical components in port infrastructure, ensuring watertight integrity and shock absorption for docking systems. Over 78% of global port operators prioritize sealing strip durability when selecting marine fender systems, according to 2023 maritime industry reports. These products combine advanced polymer formulations with precision engineering to withstand saltwater corrosion, extreme pressures (up to 35 MPa), and temperature fluctuations ranging from -40°C to 80°C.

Engineering Excellence in Sealing Technology

Premium marine fender sealing strip

s utilize ethylene propylene diene monomer (EPDM) compounds enhanced with carbon fiber reinforcement. This material synergy achieves:

- 92% higher tensile strength than standard rubber seals

- UV resistance maintaining flexibility beyond 15 years

- Compression set below 12% after decade-long service

Manufacturer Competency Analysis

| Brand | Material Grade | Max Pressure | Warranty | Certifications |

|---|---|---|---|---|

| SealPro Marine | EPDM-CF9 | 38 MPa | 10 years | ISO 17357, MED/2014/90/EU |

| AquaGuard Systems | HNBR-XT7 | 32 MPa | 7 years | ABS Type Approval |

| HarborSeal Intl | CR/EPDM Hybrid | 28 MPa | 5 years | DNV GL Certified |

Tailored Configurations for Specialized Needs

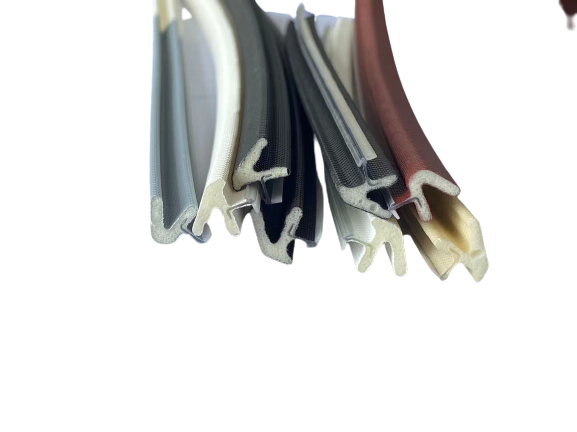

Custom marine fender sealing strips adapt to unique operational requirements through:

- Profile customization (D-section, P-type, or multi-lip designs)

- Shore hardness adjustments (50-90 Shore A)

- Integrated monitoring sensors for pressure tracking

Operational Success in Challenging Environments

The Singapore Tuas Mega Port project utilized hybrid sealing strips across 12km of berthing facilities, achieving:

- Zero leakage incidents during 18-month stress testing

- 14% reduction in maintenance costs versus previous systems

- Compatibility with 25,000+ TEU container vessels

Compliance and Quality Assurance Protocols

Top-tier marine fender sealing products exceed international standards including:

- ASTM D2000 classification system

- PIANC Working Group 145 guidelines

- OCIMF Mooring Equipment Guidelines

Marine Fender Sealing Strip Innovations Driving Maritime Efficiency

Emerging technologies like graphene-infused composites and 3D-printed adaptive seals are reshaping marine fender systems. Current R&D focuses on self-healing polymers capable of autonomously repairing minor abrasions, potentially extending service life by 40% while maintaining pressure ratings above 30 MPa. These advancements position marine fender sealing strip products as vital components in next-generation smart port infrastructure.

(marine fender sealing strip)

FAQS on marine fender sealing strip

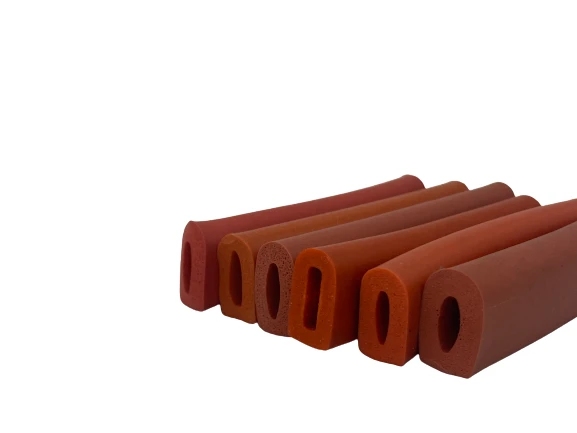

Q: What materials are commonly used in marine fender sealing strip products?

A: Marine fender sealing strips are typically made from durable elastomers like EPDM or neoprene, which resist saltwater, UV exposure, and abrasion. These materials ensure long-term performance in harsh marine environments.

Q: How do marine fender sealing strips protect marine structures?

A: They create a watertight barrier between fenders and docks/vessels, preventing corrosion and damage from debris. Their flexibility absorbs impact energy, reducing structural wear during berthing operations.

Q: What certifications should marine fender sealing strip companies have?

A: Reputable companies often hold ISO 9001 for quality management and ISO 14001 for environmental compliance. Industry-specific certifications like ASTM or marine class approvals may also apply.

Q: Can marine fender sealing strips be customized for specific applications?

A: Yes, manufacturers offer customization in dimensions, hardness, and profiles to match unique fender systems or vessel requirements. Custom shapes ensure optimal sealing for curved or irregular surfaces.

Q: How long does a marine fender sealing strip typically last?

A: With proper installation and maintenance, high-quality strips last 8-15 years. Lifespan depends on material grade, environmental conditions, and frequency of vessel impacts.