Des . 24, 2024 18:26 Back to list

Factory for Photovoltaic Solar Panel Sealing Strip Manufacturing and Development

The Importance of Photovoltaic Solar Panel Slit Seal Strips

As the world shifts towards more sustainable energy solutions, photovoltaic (PV) solar panels have emerged as a key player in harnessing renewable energy. With their ability to convert sunlight into electricity, they offer an effective solution to the growing demand for energy while reducing carbon emissions. However, to ensure the efficiency and longevity of solar panels, the role of various components, such as slit seal strips, cannot be overlooked. In this article, we will explore the significance of slit seal strips in the manufacturing of photovoltaic solar panels and the operation of factories that produce these essential components.

Understanding Slit Seal Strips

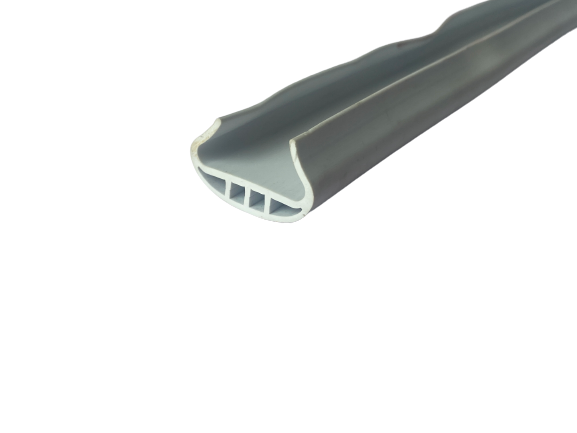

Slit seal strips are specialized components used in the assembly of photovoltaic solar panels. These strips are inserted into the gaps or slits between the layers of the solar panel. They serve multiple purposes, primarily protecting the internal components from external elements such as moisture, dust, and dirt, which can severely hinder the performance of solar cells. Additionally, slit seal strips help to maintain the structural integrity of the panels, ensuring that they remain durable and efficient over their intended lifespan.

Factors Driving the Demand for Slit Seal Strips

The demand for slit seal strips has significantly increased due to the growing popularity of solar energy. Globally, many governments are investing in renewable energy solutions, promoting solar energy through incentives and subsidies. As more companies and homeowners opt for solar installations, the need for high-quality, reliable components has become paramount. Furthermore, advancements in technology and materials have led to improvements in the performance of solar panels, thereby increasing the need for effective sealing solutions.

The Manufacturing Process of Slit Seal Strips

photovoltaic solar panel slit seal strip factory

The production of slit seal strips occurs in specialized factories equipped with advanced machinery and skilled labor. The manufacturing process typically involves several stages

1. Material Selection High-quality materials are essential for producing durable slit seal strips. Commonly used materials include EPDM (ethylene propylene diene monomer) rubber, silicone, and various thermoplastics, each chosen for their unique properties such as weather resistance, flexibility, and longevity.

2. Extrusion Once the appropriate materials are selected, they undergo the extrusion process, where they are heated and forced through a die to create strips of the desired shape and size. This process ensures uniformity and precision, which are critical for the effective sealing of solar panels.

3. Quality Control After extrusion, the strips undergo rigorous quality control tests. Inspections are conducted to ensure that the dimensions, flexibility, and sealing properties meet industry standards. Any defective strips are discarded to maintain high quality in the final product.

4. Packaging and Distribution Once approved, the slit seal strips are carefully packaged and distributed to solar panel manufacturers. Timely delivery and reliability in supply chains are essential factors to ensure that solar panel production remains uninterrupted.

Conclusion

In conclusion, slit seal strips play a vital role in the manufacturing and performance of photovoltaic solar panels. As the renewable energy market continues to grow, the importance of high-quality components cannot be overstated. Factories specializing in the production of slit seal strips are crucial to this industry, providing the necessary parts that ensure the efficiency and longevity of solar panels. By investing in innovative technologies and high-quality manufacturing processes, these factories not only contribute to the sustainability of energy but also support the broader goal of combating climate change. As solar energy continues to gain traction, the role of components like slit seal strips will become increasingly significant, highlighting the importance of quality in every aspect of solar panel production.