Sep . 19, 2024 20:29 Back to list

waterproof and soundproof car window rubber sealing strip factory

The Importance of Waterproof and Soundproof Car Window Rubber Sealing Strips

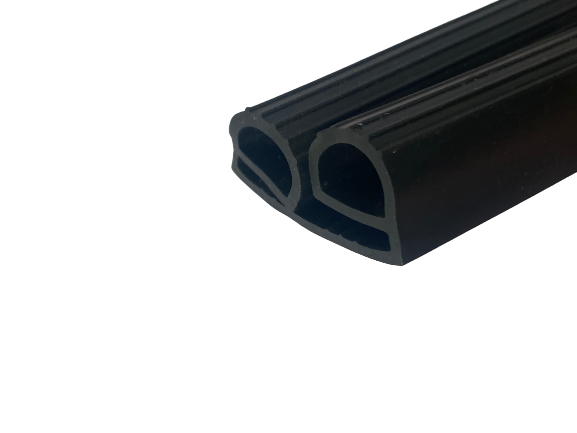

In the automotive industry, the significance of car window rubber sealing strips cannot be understated. These unassuming components play a crucial role in ensuring vehicle integrity by providing both waterproof and soundproof barriers. As consumers become increasingly aware of quality and comfort in their vehicles, the demand for high-performance sealing strips has surged, prompting advancements in manufacturing and material technology.

Waterproof Features

One of the primary functions of rubber sealing strips is to prevent water from entering the vehicle, which can lead to a multitude of problems including rust, mold, and electrical issues. Waterproof sealing strips are designed to form a tight seal around the window edges, safeguarding the interior from rain and splashes.

With advancements in manufacturing processes, modern sealing strips are produced using high-quality materials that exhibit excellent resistance to water penetration. Factories specializing in these products utilize precision molding techniques to ensure that each strip fits snugly into the window frame. This meticulous approach not only enhances the waterproof capabilities but also improves the overall durability of the sealing strips, prolonging their lifespan and reducing the need for frequent replacements.

Soundproof Capabilities

In addition to waterproof qualities, soundproofing is another essential function of rubber sealing strips. Noise from external sources can significantly affect the driving experience, making it less enjoyable and more stressful. High-quality sealing strips are engineered to minimize sound transmission, providing a quieter cabin environment.

waterproof and soundproof car window rubber sealing strip factory

The soundproofing effectiveness of rubber sealing strips stems from their ability to absorb and dampen vibrations. Through the use of advanced materials such as EPDM (Ethylene Propylene Diene Monomer), manufacturers are able to create seals that not only block water but also significantly reduce noise pollution from traffic, wind, and construction. This is particularly important for luxury vehicles and electric cars, where an exceptionally quiet operation is often a key selling point.

Manufacturing Processes

The production of waterproof and soundproof car window rubber sealing strips involves several intricate processes. Leading factories employ a combination of extrusion and molding techniques to create strips that meet stringent quality standards.

The extrusion process allows for the continuous production of rubber strips in various lengths and shapes, while molding is used for more complex profiles. Additionally, rigorous quality control measures are implemented throughout the manufacturing process to ensure that the final products meet industry specifications regarding thickness, elasticity, and resistance to wear and environmental factors.

Conclusion

In conclusion, the role of waterproof and soundproof car window rubber sealing strips is vital to the overall performance and comfort of vehicles. As the automotive market continues to evolve, manufacturers are dedicated to improving these components to meet consumer demands for higher quality and better performance. Investing in top-notch sealing strips not only enhances the vehicle's durability but also elevates the driving experience, making it a worthy consideration for automotive manufacturers and consumers alike. Whether in the context of new vehicle production or aftermarket upgrades, the importance of reliable sealing solutions remains paramount.