Product Description:

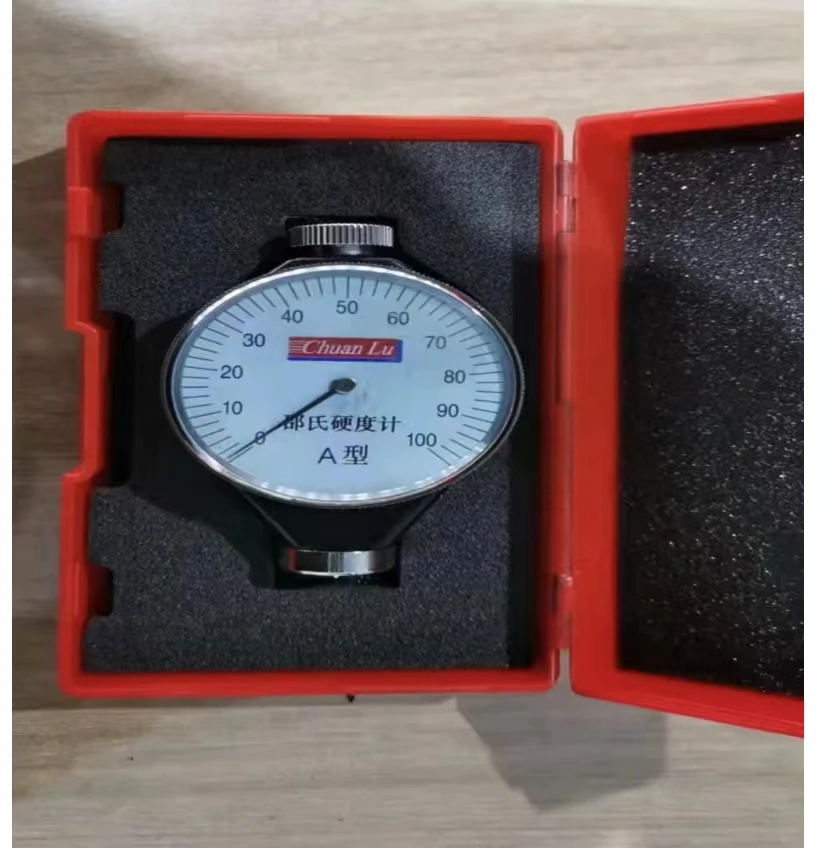

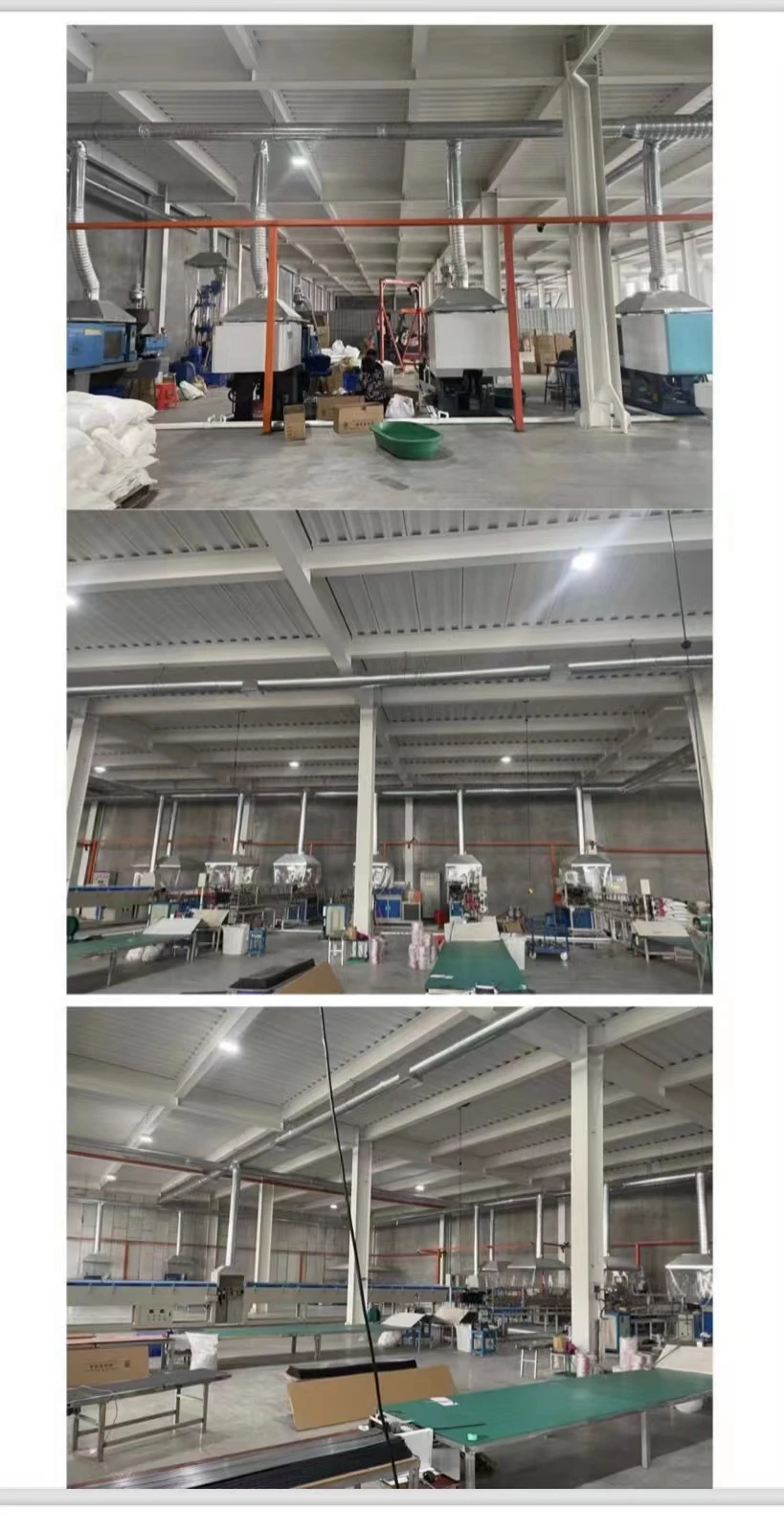

The rubber plate is made by rolling or extrusion molding, and is vulcanized by a flat vulcanizing machine or continuously vulcanized by a drum vulcanizing machine. To ensure a flat surface, the rubber plate is cut by an automatic machine.

EPDM rubber sheet has high tear resistance, good oil resistance, high temperature resistance, corrosion resistance, aging resistance and strong elasticity; Used for working in oil media in low and high temperature environments, capable of punching oil seals, washers, and seals, with good sealing performance, suitable for environments with high corrosion resistance requirements; Features: Green and environmentally friendly, drum vulcanization machines produce seamless, one-time molding, pollution-free, wear-resistant, corrosion-resistant, and high and low temperature resistant products.

In industrial occupations, rubber sheets are mainly used for anti-corrosion, wear-resistant, and impact resistant maintenance of equipment and equipment. In the mining industry, the rubber plate is mainly used for wear-resistant and impact resistant maintenance of its equipment and related pipeline equipment, which can extend the service life of its equipment. In the cultural and educational system, it is generally used for printing and plate making. With the innovative development of social technology, rubber sheets, as an emerging technological component, have been increasingly used by more and more professions, with a wide range of applications and uses. In industrial and mining enterprises, transportation departments, and construction industries, such as houses and floors, this material has played a unique role.

Hebei Zhouge Plastic Technology Co., Ltd. was established in 2014 and is committed to providing one-stop protection for fire prevention, smoke prevention, sound insulation, ventilation and sealing. By implementing this strategy, we have achieved a leading advantage. Firstly, provide cost-effective and reliable products for customers; Secondly, by integrating different product solutions to meet customer needs; Third, provide customers with one-stop, differentiated quality services, including detailed design, material solution consulting, supply chain management, quality control and financial support; Finally, always maintain innovation in technology and management.