Dic . 13, 2024 20:57 Back to list

Automotive Door Seal Solutions for Enhanced Vehicle Performance and Weather Resistance

The Importance of Automotive Door Seals in Vehicle Design

Automotive door seals are a crucial yet often overlooked component in vehicle design. They play a vital role in ensuring the overall functionality and comfort of a vehicle. As manufacturers strive to enhance the driving experience, the significance of high-quality door seals cannot be overstated. This article explores the various functions, materials, manufacturing processes, and innovations related to automotive door seals.

Functions of Automotive Door Seals

Automotive door seals primarily serve three critical functions sealing, insulation, and aesthetic enhancement. The sealing capability is essential to prevent water, dust, and air from entering the cabin, which contributes significantly to passenger comfort. A well-sealed door can protect the interior from the elements, ensuring that drivers and passengers remain dry and comfortable in inclement weather.

Insulation is another critical function of door seals, as they help reduce noise levels within the vehicle. Road noise, wind noise, and external sounds can be distracting and uncomfortable for occupants. High-quality door seals minimize these disturbances, providing a quieter and more serene driving experience. Furthermore, seals also contribute to energy efficiency by keeping the cabin temperature stable, thereby reducing the load on the heating and cooling systems.

Aesthetically, door seals contribute to the overall design of the vehicle. They ensure that doors align perfectly with the body of the car, providing a sleek, finished look. This alignment is not only crucial for appearance but also vital for aerodynamic performance.

Materials Used in Automotive Door Seals

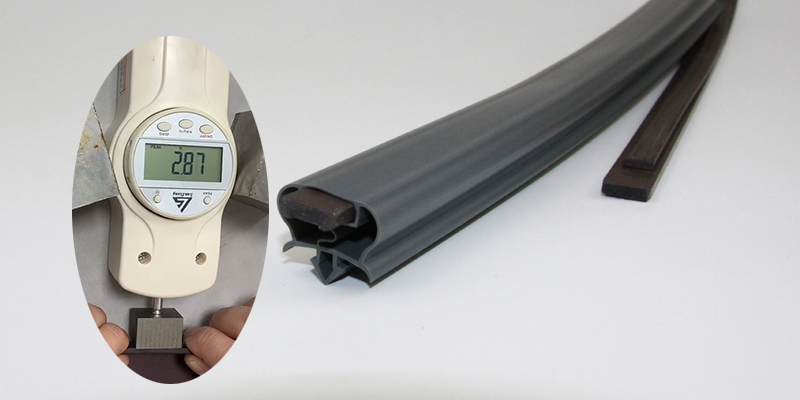

Automotive door seals are typically made from a variety of materials, each chosen for specific performance characteristics. Common materials include rubber, thermoplastic elastomers (TPE), and polyurethane foams. Rubber is widely used due to its excellent resilience and durability. It can withstand the stresses of opening and closing doors and is resistant to various environmental factors such as UV radiation, ozone, and temperature fluctuations.

Thermoplastic elastomers (TPE) have gained popularity due to their flexibility and ease of manufacturing. TPEs can be molded into complex shapes, allowing for more efficient design features and easier integration into vehicle production. Additionally, they can offer non-toxic, recyclable options, appealing to environmentally conscious manufacturers and consumers alike.

automotive door seal

Polyurethane foams, on the other hand, are often used in conjunction with rubber or TPE to provide enhanced insulation properties. By combining these materials, manufacturers can create composite seals that optimize both sealing and insulating performance.

Manufacturing Processes

The manufacturing of automotive door seals involves several sophisticated processes, including extrusion, molding, and assembly. Extrusion is a key method wherein raw material is forced through a die to create a continuous seal of a specific profile. This process allows for rapid production and is highly efficient.

Molding is another essential process, particularly for producing complex shapes or specific features within the door seal. Techniques such as injection molding and compression molding are commonly employed, depending on the material properties and design requirements.

The assembly involves integrating the door seals into the vehicle's door assembly during manufacturing. Proper alignment and installation are crucial to ensure the seals perform as intended, providing optimal sealing, insulation, and durability over the life of the vehicle.

Innovations in Door Seal Technology

As the automotive industry evolves, so do the technologies surrounding door seals. Advancements in materials science, automation, and design software are paving the way for innovative solutions. For instance, some manufacturers are exploring the use of smart materials that can adjust their properties in response to environmental changes, enhancing the sealing performance dynamically.

Moreover, the push towards electric vehicles (EVs) has led to new considerations in door seal design. The unique requirements of EVs, including increased battery safety and insulation needs, have inspired the development of specialized seals that cater specifically to these vehicles.

In conclusion, automotive door seals are a fundamental element that impacts a vehicle’s performance, comfort, and aesthetic appeal. As technology continues to advance, the materials and manufacturing processes used to create these vital components will only improve, leading to better vehicles and enhanced driving experiences. Investing in high-quality door seals is an investment in quality and comfort, underscoring their critical role in vehicle design.