Nov . 15, 2024 22:03 Back to list

ce certification marine fender seals can be customized

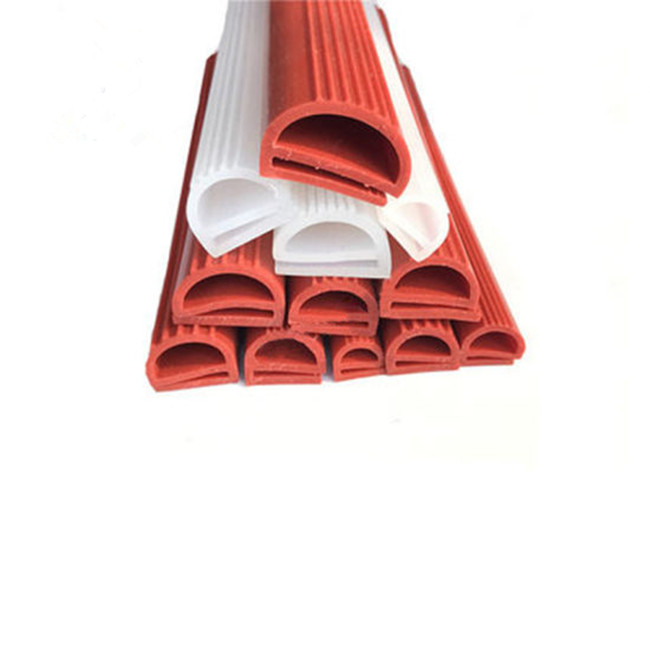

Customized CE Certification Marine Fender Seals Ensuring Safety and Efficiency in Maritime Operations

In the maritime industry, safety is paramount, especially when it comes to docking and berthing operations. One crucial component that plays a vital role in these processes is the marine fender system. Marine fenders are engineered to absorb the energy of incoming vessels, protecting both the ships and the docking infrastructure. Among the various components of marine fender systems, seals are fundamental to enhancing performance and durability. Today, the focus is on CE certification marine fender seals, which can be customized to meet specific requirements.

Understanding CE Certification

CE marking is a certification mark indicating that a product meets European Union (EU) safety, health, and environmental protection standards. In the context of marine fender seals, CE certification assures clients that these products comply with stringent quality and safety standards. This certification is essential for companies operating in European waters or those exporting marine products to Europe, as it signifies that the products are fit for their intended use and will not pose a hazard to users or the environment.

Importance of Customized Marine Fender Seals

Not all marine operations are the same, and the unique characteristics of different docking facilities, vessel types, and environmental conditions necessitate tailored solutions. Customized marine fender seals offer several advantages

1. Fit for Purpose Every port and docking facility has its own layout, vessel specifications, and operational demands. Customized seals ensure a perfect fit, providing optimal performance and safety.

2. Material Selection The choice of materials impacts the durability and functionality of marine fender seals. Customization allows for the selection of materials resistant to harsh marine environments, ensuring longevity and reliability.

3. Performance Optimization Different vessels exert varying amounts of force during docking. Customized seals can be designed to withstand specific impact energies, thus enhancing the overall efficiency of the fender system.

4. Aesthetic Considerations In some cases, aesthetic considerations can also play a role in the design of marine fender seals. Custom solutions can align with the branding or visual requirements of a particular port facility.

ce certification marine fender seals can be customized

The Customization Process

The process of customizing marine fender seals typically involves several key steps

1. Assessment of Requirements A comprehensive evaluation of the docking environment, vessel specifics, and operational conditions is conducted. This assessment helps in identifying the precise needs for the fender seals.

2. Design and Engineering Using advanced technology such as Computer-Aided Design (CAD), engineers develop detailed designs that incorporate the required specifications. This stage includes considerations for geometry, material selection, and performance metrics.

3. Prototyping Before full-scale production, prototypes of the seals are created and tested. This ensures that the final product meets all expectations in terms of performance and safety.

4. Testing and Certification All customized seals are subjected to rigorous testing to ensure compliance with CE certification standards. This testing includes impact resistance, durability assessments, and environmental exposure trials.

5. Production and Delivery Once the prototypes are approved, the seals move into production. High-quality manufacturing processes ensure that each seal meets the specified design criteria.

Conclusion

Customized CE certification marine fender seals are vital for enhancing the safety and efficiency of maritime operations. By ensuring that these seals meet rigorous quality standards and are tailored to specific operational needs, ports and shipping companies can significantly reduce the risks associated with docking activities. The flexibility in customization not only optimizes performance but also aligns with the unique requirements of various maritime environments, ensuring that every vessel docking is met with the utmost safety and care. Investing in such tailored solutions is a crucial step towards a safer and more efficient maritime industry.

Next:

Prev: