Dic . 04, 2024 08:15 Back to list

High-Quality ODM EPDM Rubber Sheets for Versatile Applications and Durability

Understanding ODM EPDM Rubber Sheets Applications and Benefits

EPDM (Ethylene Propylene Diene Monomer) rubber sheets have gained significant popularity in various industries due to their exceptional properties. When it comes to custom manufacturing, Original Design Manufacturer (ODM) services provide tailored solutions to meet specific demands, making ODM EPDM rubber sheets an ideal choice for businesses seeking high-quality materials.

What is EPDM Rubber?

EPDM is a type of synthetic rubber known for its outstanding resistance to weathering, ozone, and UV radiation. Its unique molecular structure offers excellent durability and resilience, making it suitable for a wide range of applications. EPDM is commonly used in roofing membranes, automotive parts, seals, gaskets, and more, thanks to its ability to maintain performance in extreme temperatures, from -40°F (-40°C) to 212°F (100°C).

Features of ODM EPDM Rubber Sheets

1. Customization One of the primary benefits of ODM services is the ability to customize EPDM rubber sheets to meet specific requirements. Whether businesses need different thicknesses, sizes, or colors, ODM manufacturers can produce sheets tailored to precise specifications. This level of customization can enhance product compatibility and performance in various applications.

2. Durability EPDM rubber sheets are renowned for their durability. They can withstand harsh environmental conditions, making them perfect for outdoor applications. The resistance to environmental stress cracks, aging, and weathering ensures that these sheets maintain their integrity and functionality over time.

3. Flexibility The high elasticity of EPDM allows it to stretch and adapt to various shapes and surfaces. This characteristic is particularly beneficial in applications where movement or vibrations occur, such as in automotive and industrial settings.

4. Chemical Resistance EPDM rubber exhibits excellent resistance to a wide range of chemicals, including acids and alkalis. This resistance is crucial for industries dealing with harsh substances, ensuring the longevity and reliability of essential components.

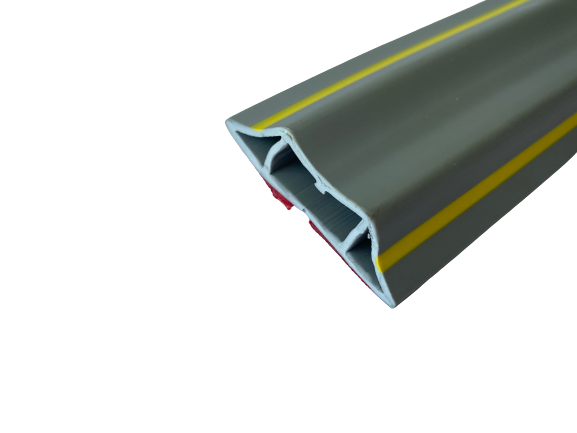

odm epdm rubber sheet

5. Thermal Stability With a remarkable ability to perform in extreme temperatures, ODM EPDM rubber sheets are often used in situations where thermal fluctuations are prevalent. This stability ensures that they can continue to function effectively regardless of temperature changes.

Applications of ODM EPDM Rubber Sheets

1. Construction In the construction industry, EPDM rubber sheets are popularly used as roofing membranes due to their water resistance and durability. They provide effective insulation, contributing to energy efficiency and protecting structures from water infiltration.

2. Automotive In vehicles, EPDM rubber is employed for various seals and gaskets, ensuring airtight and watertight closures. This usage helps in enhancing the overall efficiency of vehicles while extending the life of critical components.

3. Industrial Various industries utilize EPDM rubber sheets for manufacturing conveyor belts, protective coverings, and hoses. The versatility of EPDM allows it to be used across different sectors, from manufacturing to food processing.

4. HVAC Systems EPDM rubber sheets play a vital role in heating, ventilation, and air conditioning (HVAC) systems by providing flexible and durable seals that help maintain system efficiency.

Conclusion

In conclusion, ODM EPDM rubber sheets offer a blend of customization, durability, and versatility that meets the demands of various industries. Their ability to withstand harsh conditions, resist chemicals, and maintain performance in extreme temperatures makes them a valuable asset for any business looking to enhance its operational efficiency and product quality. Whether it’s in construction, automotive, or industrial applications, the adoption of ODM EPDM rubber sheets can lead to significant long-term benefits. As technology progresses, the potential for even more innovative applications of EPDM rubber sheets continues to expand, proving that this material is here to stay.