Dic . 16, 2024 16:40 Back to list

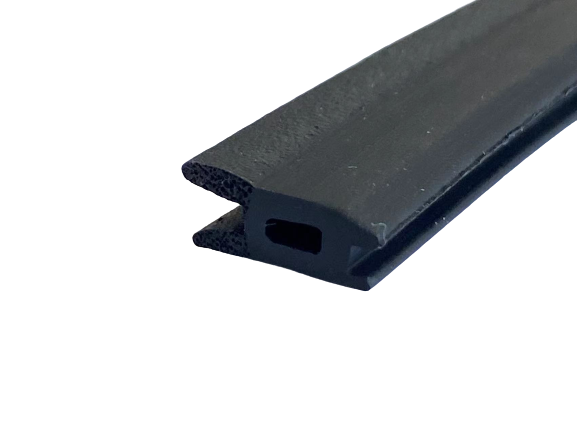

silicone rubber sealing strip

Silicone Rubber Sealing Strips Essential Components for a Leak-Free Environment

Silicone rubber sealing strips are versatile and highly effective components used in various applications, ranging from automotive industries to household products. Their unique properties, including flexibility, durability, and resistance to temperature fluctuations, make them ideal for sealing gaps and preventing leaks.

One of the most significant advantages of silicone rubber is its ability to withstand extreme temperatures. Silicone rubber sealing strips can function effectively in a broad temperature range, from -60°C to over 200°C. This makes them perfect for appliances and machinery that generate heat and require reliable sealing solutions. For example, in the automotive sector, silicone sealing strips are used around gaskets and in engine compartments, ensuring that fluids remain contained while allowing for thermal expansion.

Moreover, silicone rubber is also resistant to UV light, ozone, and harsh weather conditions. This resistance makes silicone sealing strips an excellent choice for outdoor applications, such as sealing windows and doors in homes, commercial buildings, and vehicles. By using silicone sealing strips, you can significantly enhance energy efficiency, reduce noise pollution, and maintain a comfortable indoor climate. The flexibility and compressibility of silicone allow for easy installation and adjustment, ensuring a snug fit that prevents drafts and leaks.

In addition to their practical benefits, silicone rubber sealing strips are also non-toxic and environmentally friendly. Unlike some other types of sealing materials that may release harmful chemicals over time, silicone is stable and does not off-gas, making it a safe choice for use in food storage and medical devices. Consequently, many manufacturers prefer silicone rubber sealing strips in applications that require a high level of safety and hygiene.

silicone rubber sealing strip

When it comes to installation, silicone sealing strips are incredibly user-friendly. They can be cut to size, allowing for customization based on specific needs. Many products come with adhesive backing, enabling quick and straightforward application without the need for specialized tools or heavy-duty equipment. This ease of use contributes to their growing popularity among DIY enthusiasts and professional contractors alike.

In industries where precision and reliability are paramount, such as aerospace and electronics, silicone rubber sealing strips are utilized to protect sensitive components from moisture, dust, and other contaminants. Ensuring that these materials are securely sealed is crucial in preventing failures that could result in costly repairs or dangerous situations. For this reason, many manufacturers have turned to silicone rubber due to its consistent performance under varying environmental conditions.

Moreover, the manufacturing process of silicone rubber sealing strips has advanced significantly in recent years, leading to better quality and effectiveness. With the use of advanced technology such as extrusion and molding, suppliers can produce sealing strips with specific profiles tailored to meet the unique demands of different industries. Whether it is a simple flat profile for household use or a complex custom design for industrial applications, there is likely a silicone sealing strip that fits the requirement perfectly.

In conclusion, silicone rubber sealing strips are essential components that provide reliable sealing solutions across various applications. Their impressive temperature resistance, flexibility, durability, and non-toxic nature make them an ideal choice for a wide range of industries. As technology continues to advance and the demand for quality sealing solutions grows, silicone rubber sealing strips will undoubtedly play a pivotal role in ensuring efficient and leak-free environments. Whether protecting sensitive machinery, enhancing energy efficiency in buildings, or ensuring safety in medical applications, these versatile strips are indispensable in modern manufacturing and construction.