დეკ . 12, 2024 10:46 Back to list

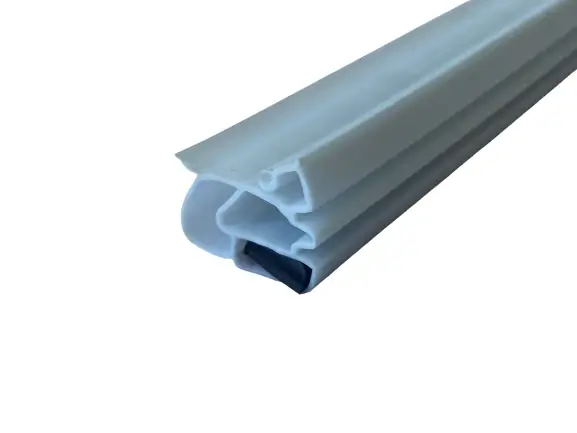

extruded rubber sealing strip

Extruded Rubber Sealing Strips A Comprehensive Overview

In the world of manufacturing and construction, the significance of sealing strips cannot be overstated. Among the various types available, extruded rubber sealing strips stand out due to their versatility, durability, and impressive sealing properties. This article delves into the characteristics, applications, benefits, and considerations of extruded rubber sealing strips, providing a comprehensive understanding of this essential component.

What are Extruded Rubber Sealing Strips?

Extruded rubber sealing strips are continuous lengths of rubber material formed through a process known as extrusion. In this process, rubber compounds are heated and then forced through a die to create a specific shape or profile. The resulting strip is characterized by its uniform cross-section, making it ideal for a wide range of applications where effective sealing is crucial.

Characteristics of Extruded Rubber Sealing Strips

1. Material Composition Extruded sealing strips can be made from various rubber materials such as EPDM (Ethylene Propylene Diene Monomer), neoprene, silicone, and nitrile rubber. Each material offers unique properties like resistance to weathering, chemicals, and extreme temperatures.

2. Customization One of the primary advantages of extruded rubber sealing strips is their ability to be customized according to specific requirements. Manufacturers can produce strips of different shapes, sizes, and lengths to fit various applications seamlessly.

3. Durability Extruded rubber sealing strips are known for their robustness. They can withstand a range of environmental conditions, including UV radiation, ozone, and moisture, making them suitable for both indoor and outdoor use.

4. Flexibility These sealing strips are designed to be flexible, enabling them to conform to different surfaces and creating an effective seal even in irregular joints or gaps.

Applications of Extruded Rubber Sealing Strips

Extruded rubber sealing strips are utilized across various industries, including

1. Automotive In the automotive sector, these sealing strips are essential for preventing water and air leaks in doors, windows, and trunk lids. They enhance the vehicle's insulation, contributing to passenger comfort and safety.

2. Construction In buildings, extruded rubber sealing strips are widely used in window and door frames to provide thermal insulation and prevent drafts. They also play a crucial role in waterproofing and soundproofing applications.

extruded rubber sealing strip

3. Electronics The electronics industry employs these sealing strips to protect sensitive components from dust, moisture, and electromagnetic interference.

4. Industrial Equipment In machinery and equipment, extruded rubber sealing strips are used to prevent the escape of fluids and gases, ensuring efficient operation and safety.

Benefits of Using Extruded Rubber Sealing Strips

1. Cost-Effectiveness While the initial investment in extruded rubber sealing strips may seem significant, their durability and effectiveness lead to reduced maintenance and replacement costs in the long run.

2. Energy Efficiency Effective sealing can significantly enhance energy efficiency by minimizing heat loss or gain within buildings and vehicles. This not only leads to lower energy bills but also contributes to environmental sustainability.

3. Improved Aesthetics Beyond functionality, extruded rubber sealing strips can improve the overall aesthetic appeal of products or structures by providing a neat finishing touch.

Considerations When Choosing Extruded Rubber Sealing Strips

1. Temperature Resistance Depending on where the sealing strips will be used, it is essential to choose a material that can tolerate the expected temperature ranges.

2. Application Environment Consider the environmental conditions, such as exposure to chemicals, oils, or UV light, which may impact the longevity and effectiveness of the sealing strip.

3. Installation Requirements Evaluate the installation process and compatibility with existing structures to ensure optimal performance.

Conclusion

Extruded rubber sealing strips are invaluable components in numerous applications, providing effective sealing solutions that enhance performance, durability, and efficiency. Their customizable nature and robust characteristics make them suitable for a broad spectrum of industries. As businesses and manufacturers continue to prioritize quality and sustainability, investing in high-quality extruded rubber sealing strips is a wise choice that can lead to long-term benefits and improved product performance. Whether in construction, automotive, or industrial applications, these sealing strips play a crucial role in ensuring operational excellence and reliability.