დეკ . 23, 2024 22:44 Back to list

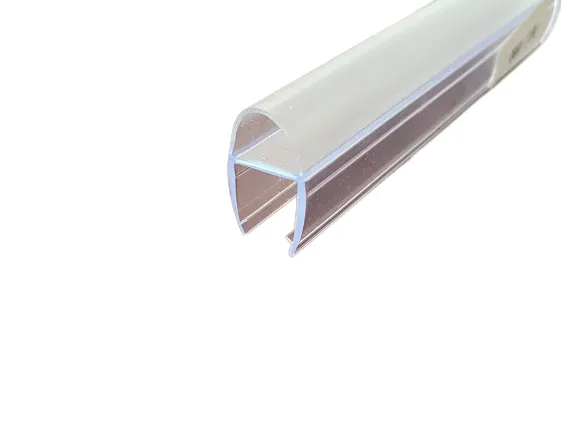

marine fender rubber sealing strip product

Marine Fender Rubber Sealing Strip An Essential Component for Marine Safety

Marine environments present unique challenges, particularly when it comes to ensuring the safety and integrity of vessels during docking and mooring operations. One critical component that plays a vital role in these scenarios is the marine fender rubber sealing strip. These strips are specifically engineered to absorb impacts, reduce wear and tear on both the fender and the docked vessels, and provide an added layer of protection against water ingress.

Understanding Marine Fender Systems

Fender systems are crucial for protecting boats, barges, and ships from potential damage when they come into contact with docks or other vessels. They are typically made from high-quality rubber, which has excellent resilience and energy-absorbing properties. However, the effectiveness of these fender systems can be significantly enhanced by incorporating rubber sealing strips.

The Role of Rubber Sealing Strips

Rubber sealing strips serve several essential functions within marine fender systems

1. Impact Absorption As vessels dock, they generate significant force upon contact with the fender. Rubber sealing strips help to absorb this impact, reducing the risk of damage to both the fender itself and the vessel.

2. Water Protection One of the most critical aspects of marine operations is preventing water from entering compartments of ships or docks. The rubber sealing strip provides a tight seal that minimizes the risk of water ingress, crucial for maintaining the integrity of vessel structures.

marine fender rubber sealing strip product

3. Enhancing Durability The harsh marine environment can be unforgiving. Rubber sealing strips are designed to withstand extreme weather conditions, UV radiation, and saltwater corrosion. This durability extends the lifespan of the fender and ensures reliable performance in all conditions.

4. Noise Reduction The cushioning effect of rubber sealing strips also plays a role in noise reduction. When vessels collide with fenders, the impact can create substantial noise pollution. Sealing strips help to dampen these sounds, making for a more pleasant harbor environment.

Selecting the Right Material

The choice of material for marine fender rubber sealing strips is crucial. Typically, high-quality elastomers with excellent tensile strength, flexibility, and resistance to degradation from environmental factors are used. Commonly used materials include EPDM (Ethylene Propylene Diene Monomer) and NR (Natural Rubber), both of which offer excellent performance in marine applications.

Installation and Maintenance

Proper installation and maintenance of rubber sealing strips are essential for their effectiveness. It is important to ensure that the sealing strips are fitted correctly to create a watertight seal and that they are regularly inspected for wear and damage. Over time, exposure to marine conditions and physical impacts can lead to wear and degradation, so timely replacement is critical to maintaining safety and functionality.

Conclusion

In summary, marine fender rubber sealing strips are an indispensable part of marine safety systems. By providing impact absorption, preventing water ingress, improving durability, and reducing noise, these seals contribute significantly to the operational effectiveness of marine vessels. As maritime industries continue to evolve, the importance of investing in quality marine fender systems and their components cannot be overstated. Ensuring that these rubber sealing strips are designed, installed, and maintained properly is key to protecting both vessels and docks, ultimately safeguarding the safety and efficiency of maritime operations. As maritime activities expand, the demand for reliable marine fender systems—including rubber sealing strips—will continue to grow, underscoring their importance in the industry.