ოქტ . 01, 2024 21:54 Back to list

EPDM Oil Tank Gaskets for ODM Applications and Their Benefits

Understanding ODM EPDM Oil Tank Gaskets

In the petroleum industry, maintaining the integrity of storage tanks is crucial for safety, environmental protection, and operational efficiency. One of the critical components that contribute to this integrity is the gasket, specifically oil tank gaskets made from Ethylene-Propylene-Diene Monomer (EPDM) rubber. This article aims to explore the features, benefits, and applications of ODM EPDM oil tank gaskets.

What is EPDM?

EPDM is a type of synthetic rubber known for its excellent resistance to heat, oxidation, and ozone, making it an ideal material for outdoor applications. Its durability and flexibility make it suitable for use in environments where temperature fluctuations occur. EPDM gaskets are widely recognized for their ability to withstand harsh conditions, including exposure to petroleum products, which is particularly important in oil storage applications.

Significance of Oil Tank Gaskets

Oil tank gaskets play an essential role in ensuring that tanks remain leak-proof, thereby preventing spills and reducing the risk of contamination. A well-fitted gasket creates a reliable seal between the tank and other components, such as the lid or access hatch, ensuring that no harmful substances escape into the environment. This is crucial for compliance with environmental regulations and for protecting public health.

Features of ODM EPDM Oil Tank Gaskets

1. Chemical Resistance One of the main advantages of ODM EPDM oil tank gaskets is their excellent resistance to a wide range of oils and fuels. This property helps prevent degradation that can lead to leaks or failures, ensuring long-lasting performance.

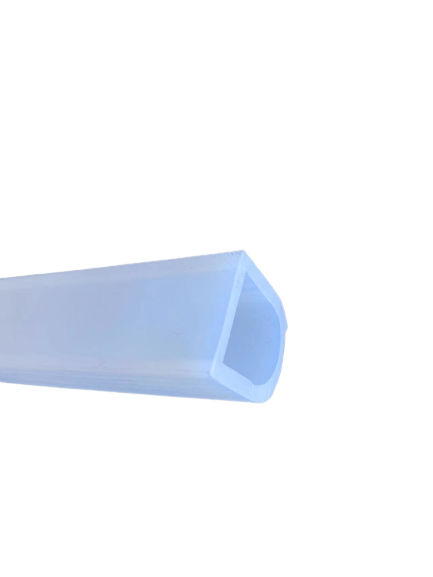

odm epdm oil tank gasket

2. Temperature Tolerance EPDM gaskets can typically withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C). This temperature resilience makes them suitable for various geographic locations and climates.

3. Flexibility and Compression Set Resistance EPDM maintains its flexibility even after prolonged use, which is vital for achieving a tight seal. Moreover, it exhibits low compression set, meaning it retains its shape after being compressed, which further enhances its sealing capabilities.

4. Durability EPDM is resistant to wear and tear from environmental stressors such as UV rays and moisture. This durability means that gaskets can last longer with minimal maintenance, reducing downtime and replacement costs.

Applications

ODM EPDM oil tank gaskets are extensively used in several applications within the oil and gas industry. They are employed in

- Storage Tanks Sealing joints to prevent leaks and protect stored oil. - Refineries Ensuring process integrity in various stages of oil refining. - Transport Tanks Providing secure seals during the transportation of fuel and other petrochemical substances.

Conclusion

In summary, ODM EPDM oil tank gaskets are a vital component in the oil industry, providing essential sealing solutions that ensure safety and compliance with environmental standards. Their remarkable properties—chemical resistance, durability, and flexibility—make them an ideal choice for oil storage and transportation applications. As the industry continues to grow, investing in quality gaskets will be pivotal in maintaining operational efficiency and protecting our environment. For anyone involved in petroleum storage or distribution, selecting high-quality EPDM gaskets is not merely a choice; it’s a necessity for a sustainable future.