ნოე . 04, 2024 10:23 Back to list

Factories for Waterproof and Soundproof Rubber Sealing Strips for Car Windows

The Importance of Waterproof and Soundproof Car Window Rubber Sealing Strips

In today's automotive industry, the demand for enhanced vehicle performance and comfort has led manufacturers to focus on various components that ensure a superior driving experience. Among these components, waterproof and soundproof car window rubber sealing strips have become essential. These seals play a critical role in maintaining the structural integrity of vehicles while significantly improving passenger comfort.

The Function of Rubber Sealing Strips

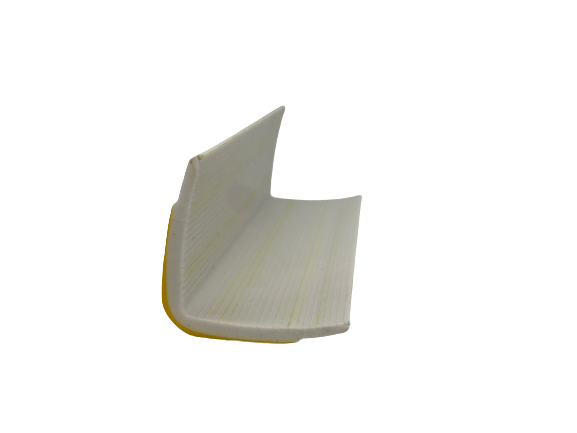

Rubber sealing strips are designed to fill the gaps between car windows and the body of the vehicle. Their primary functions include preventing water leaks, keeping out dust and dirt, and minimizing noise intrusion from the outside environment. This not only enhances the aesthetics of the vehicle but also protects its interior from potential damage caused by water or debris.

1. Waterproofing One of the most crucial features of rubber sealing strips is their ability to create a watertight barrier. This is particularly important in regions with heavy rainfall or snowy conditions, where water can easily seep into the vehicle. High-quality waterproof sealing strips ensure that rainwater drains away without entering the cabin, thus preventing mold growth and other moisture-related issues.

2. Soundproofing In addition to waterproofing, these seals also contribute significantly to soundproofing. Noise pollution from the external environment can distract drivers and make journeys less enjoyable. Effective soundproof rubber strips can muffle sounds from traffic, construction, and nature, allowing for a quieter ride. This is especially important for luxury vehicles where a serene atmosphere is a hallmark of the brand.

Manufacturing Processes

The production of waterproof and soundproof rubber sealing strips involves advanced manufacturing techniques to ensure quality and durability

. Factories specializing in these components utilize high-grade materials, often synthetic rubber or thermoplastic elastomers, which offer resilience against wear and tear.1. Material Selection The choice of materials is paramount. Manufacturers typically use compounds that combine flexibility with strength, allowing for easy installation while ensuring long-term effectiveness. Specialty additives are also incorporated to enhance properties like UV resistance and temperature stability.

waterproof and soundproof car window rubber sealing strip factories

2. Extrusion and Molding The rubber is usually shaped through processes like extrusion and molding. In extrusion, heated rubber is forced through a die to create strips of desired dimensions. Molding allows for the creation of more complex shapes that may be necessary for specific vehicle designs.

3. Quality Control Factories implement stringent quality control measures throughout the production process. Sample tests are conducted to measure the performance of the sealing strips under various conditions, including exposure to water and sound waves. This ensures that only the best products reach the automotive manufacturers.

Market Trends and Demand

With growing public awareness of sustainability and energy efficiency, there is an increasing demand for vehicles that minimize environmental impact. Rubber sealing strips contribute to this trend by helping vehicles achieve better thermal insulation and aerodynamics, which in turn may lead to reduced fuel consumption.

According to industry research, the global market for automotive rubber seals is expected to grow as more manufacturers recognize the benefits of investing in high-quality sealing solutions. This growth is propelled by the rising production rates of electric vehicles, which often feature advanced sealing technologies to enhance battery efficiency and overall performance.

Conclusion

Waterproof and soundproof car window rubber sealing strips are an integral part of modern vehicle design, ensuring that vehicles are not only functional but also comfortable for passengers. As the automotive industry continues to evolve, the importance of these seemingly simple components cannot be overstated. With advancements in materials and manufacturing processes, the future looks promising for the development of even more effective sealing solutions that cater to consumer demands for quality, comfort, and sustainability.

Investing in high-quality rubber sealing strips is not just an operational necessity for car manufacturers but also a commitment to enhancing the overall driving experience. As consumers become more discerning, the expectation for quieter rides and moisture-free environments will drive further innovations in this crucial automotive segment.