dec . 03, 2024 17:11 Back to list

Leading EPDM Rubber Sheet Suppliers for Quality and Durability in Industrial Applications

Understanding EPDM Rubber Sheet Manufacturers

Ethylene Propylene Diene Monomer (EPDM) rubber is a type of synthetic rubber that has gained significant traction across various industries due to its remarkable properties and versatility. This compound is known for its excellent weather resistance, high elasticity, durability, and thermal stability. EPDM rubber sheets are widely used in applications such as roofing, automotive parts, electrical insulation, and various forms of industrial applications. As demand grows, so does the number of EPDM rubber sheet manufacturers, each vying to provide quality products that cater to diverse customer needs.

Importance of Choosing the Right Manufacturer

Selecting the right EPDM rubber sheet manufacturer is crucial for ensuring that the products meet specific requirements in terms of quality and performance. A reliable manufacturer should have a proven track record in producing high-grade EPDM rubber sheets that conform to industry standards. High-quality sheets must withstand harsh weather conditions, resist UV rays, and maintain their flexibility over a broad temperature range.

Moreover, a reputable manufacturer should have state-of-the-art facilities equipped with advanced technology for mixing, molding, and curing rubber. This not only ensures the quality of the products but also allows manufacturers to innovate and improve their offerings continuously. Additionally, companies that prioritize research and development can adapt to changing requirements and customer needs more effectively.

Key Features and Benefits of EPDM Rubber Sheets

EPDM rubber sheets are favored for several reasons. For starters, their excellent weather resistance makes them ideal for outdoor applications, such as roofing membranes and seals, which require longevity and minimal maintenance. They are also resistant to ozone, UV light, and oxidation, ensuring that they can endure long exposure to the elements without degrading.

Furthermore, EPDM rubber sheets exhibit exceptional thermal properties. They can handle a wide temperature range, typically from -40°F (-40°C) to 212°F (100°C), making them suitable for both hot and cold environments. This thermal stability translates to lower costs incurred from maintenance and replacement.

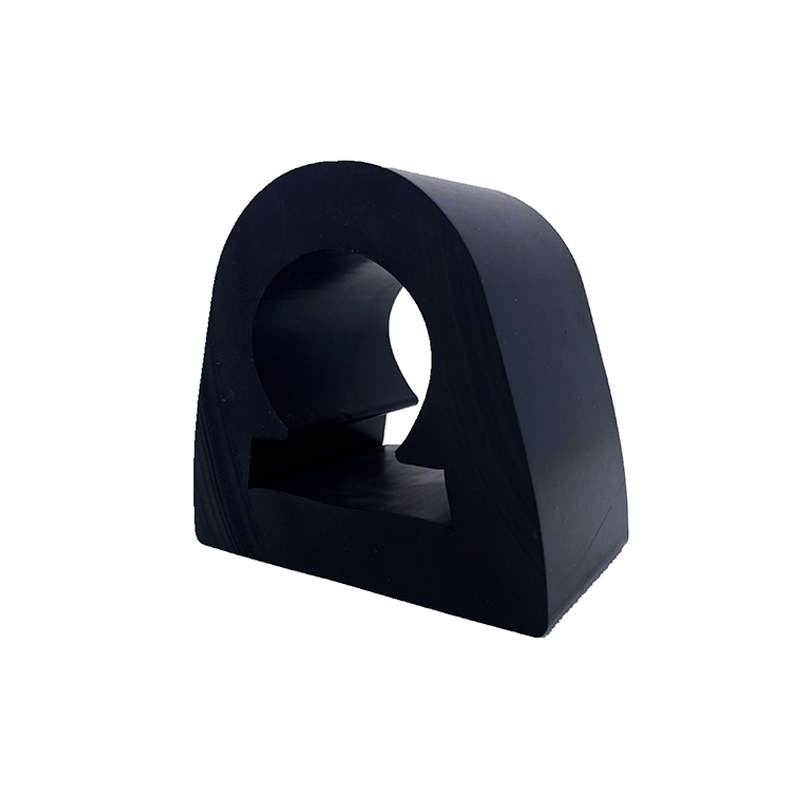

epdm rubber sheet manufacturers

Another significant benefit is EPDM's inherent waterproofing properties, making it an ideal material for sealing applications. It is often used in diverse scenarios, from sealing windows and doors to automotive weather stripping. Furthermore, EPDM rubber is compatible with many materials and surfaces, enhancing its usability in various industrial processes.

Manufacturing Process and Quality Control

The manufacturing process of EPDM rubber sheets involves several key stages, including compounding, curing, and testing. First, the rubber is compounded with various additives to enhance its properties. These additives can include fillers, accelerators, and stabilizers tailored to meet specific demands.

Following compounding, the rubber undergoes molding or calendaring to form sheets of desired dimensions. The curing process, also known as vulcanization, cross-links the rubber molecules, endowing the final product with strong structural integrity and elastic properties.

Quality control is paramount in the manufacturing process. Reputable manufacturers conduct rigorous testing on the finished sheets to ensure they meet predefined specifications and perform optimally in intended applications. Testing may include assessments of tensile strength, elongation, hardness, and resistance to chemicals and environmental factors.

Conclusion

The growth of EPDM rubber sheet manufacturers signifies the increasing recognition of the material's advantages across various industries. By focusing on quality, innovation, and customer satisfaction, manufacturers play a vital role in making EPDM rubber an essential component in numerous applications. When selecting an EPDM rubber sheet manufacturer, it is crucial to evaluate their experience, technological capabilities, and product offerings to ensure that you receive the highest quality materials tailored to your specific needs. As industries continue to evolve and adopt advanced materials, EPDM rubber sheets will remain an integral part of sustainable and efficient solutions for a variety of applications.