dec . 05, 2024 14:36 Back to list

Reinforced Neoprene Rubber Sheet for Durable and Versatile Applications

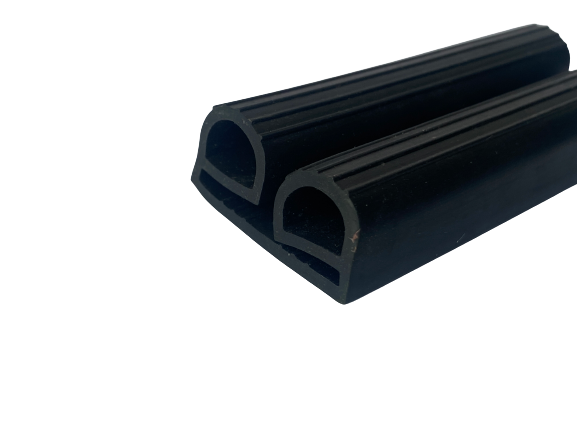

Reinforced Neoprene Rubber Sheet A Versatile Material for Diverse Applications

In the modern manufacturing and construction industries, material selection plays a pivotal role in determining the effectiveness and longevity of products. One such versatile material that has gained acclaim in various applications is the reinforced neoprene rubber sheet. Known for its exceptional resilience, flexibility, and durability, reinforced neoprene rubber provides an ideal solution for many industries, ranging from automotive to aerospace, construction, and even medical.

What is Reinforced Neoprene Rubber?

Neoprene, also known as polychloroprene, is a synthetic rubber that was first developed in the 1930s. It stands out for its resistance to oils, chemicals, and temperature variations, making it suitable for demanding environments. Reinforced neoprene rubber sheets incorporate a reinforcing agent—often made of fabric or other materials—into the rubber matrix to enhance strength, toughness, and overall performance. This reinforcement allows the rubber to withstand heavy loads, resist tearing, and provide extended service life.

Key Properties

1. Durability One of the most significant qualities of reinforced neoprene rubber sheets is their durability. They can withstand wear and tear, making them ideal for applications where materials are exposed to rough conditions.

2. Chemical Resistance Neoprene offers excellent resistance to a wide range of chemicals, making reinforced neoprene rubber sheets suitable for applications in chemical processing or environments where exposure to harmful substances is common.

3. Temperature Stability Neoprene can perform well in various temperature conditions, from extreme cold to moderate heat. This attribute makes it a popular choice for seals and gaskets in heavy machinery or automotive components.

4. Flexibility Despite its toughness, reinforced neoprene retains the flexibility needed for applications that require movement or bending. This feature is particularly crucial for components such as hoses, belts, and expansion joints.

5. Water Resistance The closed-cell structure of neoprene makes it water-resistant, which is pivotal in applications that are exposed to moisture or underwater environments, such as marine applications.

reinforced neoprene rubber sheet

Applications

Reinforced neoprene rubber sheets have a broad range of applications across multiple industries

- Automotive In the automotive sector, these sheets are used for gaskets, seals, and vibration dampening components. The durability and temperature resistance of neoprene make it suitable for engine components and other critical applications where reliability is essential.

- Construction In construction, reinforced neoprene rubber sheets can be used as expansion joints in structures, providing flexibility and movement accommodation. They are also employed in roofing membranes and sealants due to their waterproof characteristics.

- Aerospace The aerospace industry benefits from reinforced neoprene rubber sheets due to their lightweight and strength. They are utilized in insulation materials, seals, and cushioning applications where reducing weight while maintaining performance is crucial.

- Medical In the medical field, these rubber sheets can be found in protective gear, mats, and various devices that require durable and hygienic materials. The chemical resistance of neoprene also makes it suitable for applications involving medical fluids.

- Industrial Various industrial applications, including conveyor belts, protective gear, and machine components, utilize reinforced neoprene sheets due to their robustness and ability to handle heavy-duty tasks.

Conclusion

Reinforced neoprene rubber sheets are a prime example of how advanced material science can yield products with remarkable properties suitable for a diverse range of applications. Their combination of durability, flexibility, and resistance to a variety of harmful substances has made them indispensable in multiple industries. As manufacturing processes evolve and new challenges arise, the adaptability and reliability of reinforced neoprene will continue to play a significant role in enhancing product performance and longevity. Furthermore, ongoing research and development in materials science suggest that the applications for reinforced neoprene rubber sheets will only expand, paving the way for innovative uses well into the future. Whether it is in the automotive industry, construction sites, or high-tech aerospace applications, reinforced neoprene rubber sheets embody versatility and resilience, meeting the demands of the modern world.