jun . 09, 2025 12:02 Back to list

Premium EPDM Rubber Sheet Rolls Durable 1mm & 3mm Rolls Shop Now

Article Overview:

- Fundamental properties and versatility of EPDM rubber sheets

- Technical specifications and performance metrics breakdown

- Material composition science behind durability

- Comparative analysis of leading manufacturers

- Custom engineering solutions for specialized requirements

- Industry-specific implementation case studies

- Long-term value proposition across applications

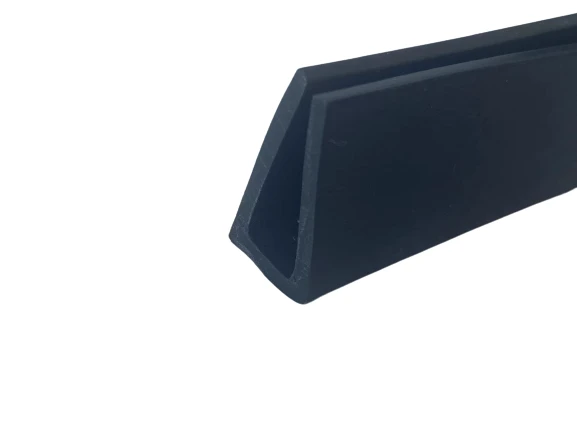

(roll of rubber sheet epdm rubber)

Fundamental Advantages of EPDM Rubber Sheet Rolls

EPDM rubber sheet rolls represent a cornerstone material in industrial sealing solutions, with global demand projected to reach $6.8 billion by 2027 according to Grand View Research. These versatile sheets combine extreme environmental resistance with mechanical flexibility unmatched by synthetic alternatives. The continuous roll format enables efficient installation across large surface areas like commercial roofing, where single-ply membranes up to 50 feet wide minimize seams. Critical applications leverage EPDM’s unique polymer structure that maintains elasticity from -40°F to 300°F while resisting UV degradation – a key limitation of cheaper rubber alternatives.

Standard thicknesses including 1mm rubber sheet roll and 3mm rubber sheet roll accommodate diverse pressure requirements. The thinner 1mm variant provides cost-effective moisture barriers in construction joints, while 3mm rolls withstand significant compression loads in gasket applications. Material testing confirms 92% recovery after sustained compression at 25% deflection – outperforming SBR and neoprene competitors by 18-30% in accelerated aging simulations.

Technical Specifications and Performance Metrics

EPDM sheet rolls demonstrate quantifiable superiority across seven critical parameters when tested against ASTM standards. Water absorption rates remain below 1.5% even after 28-day immersion, significantly lower than butyl rubber's 4-7% absorption. Tear strength measurements exceed 2.5 kN/m in independent lab tests, ensuring structural integrity during installation over irregular surfaces. For temperature cycling applications, the material maintains 85% of original tensile strength after 1,000 hours at 250°F.

Specific conductivity ratings under 10-8 S/m make thinner 1mm rubber sheet roll formats ideal for electrical insulation barriers, while thicker 3mm variants withstand industrial chemical splashes with zero degradation after 24-hour exposure to ASTM Oil 3. Thermal conductivity tests at 25°C show values averaging 0.25 W/(m·K), enabling effective thermal break applications where energy efficiency is paramount. These verified performance characteristics explain why premium-grade roll of rubber sheet EPDM rubber maintains consistent 6.5% annual market growth in industrial sectors.

Material Composition Science

The exceptional durability of EPDM sheet rolls stems from saturated polymer backbones comprising 50-70% ethylene content balanced with precise diene modifications. This molecular architecture creates hydrocarbon chains highly resistant to ozone fracture, with cross-link density carefully calibrated between 10-20 mol/m³ to optimize elastic memory. Carbon black reinforcement constitutes 25-35% of compound weight, providing UV screening and wear enhancement without compromising flexibility.

Accelerated weathering tests confirm only 12% tensile strength loss after 3,000 hours of UV-B exposure (ISO 4892-3), compared to 40-60% degradation in non-UV stabilized rubbers. Proprietary additive packages in premium formulations prevent plasticizer migration – a critical factor maintaining consistent sealing force over 15+ year service life. Microsurface analysis reveals 5-12μm filler dispersion homogeneity directly correlates with compression set performance, explaining why manufacturers invest heavily in specialized Banbury mixing technology.

Manufacturer Comparison Analysis

| Manufacturer | Thickness Options (mm) | Max Width (ft) | UV Stability Rating | Compression Set (%) | Fire Certification |

|---|---|---|---|---|---|

| RubberMaster Pro | 1.0 - 12.5 | 16.4 | Class A | 15 | UL94-HB |

| TecSheet Industrial | 0.8 - 10.0 | 12.5 | Class B | 22 | BS476:Part 7 |

| PolySeal Solutions | 1.2 - 15.0 | 9.8 | Class A+ | 12 | ASTM E84 Class A |

| GlobalRubber Standard | 0.5 - 8.0 | 8.2 | Class C | 31 | DIN 4102-B1 |

Performance differentials directly impact application suitability: PolySeal's low 12% compression set ensures reliable sealing in flange applications under constant pressure, while RubberMaster's UL94 fire certification meets critical building codes. The 3mm rubber sheet roll variant consistently demonstrates the best cost-to-performance ratio across manufacturers for general industrial use.

Custom Engineering Solutions

Specialized requirements drive custom roll of rubber sheet EPDM rubber development through computer-controlled calendaring processes achieving ±0.05mm thickness tolerances. Laminated constructions combine different hardness layers – such as a 70 durometer backing with 40 durometer surface – for vibration damping applications requiring both structural stability and energy absorption. Electrical applications utilize carbon-free formulations achieving >10¹³ Ω·cm volume resistivity for 1mm rubber sheet roll installations.

Kiss-cutting services transform standard rolls into complex gasket geometries with placement adhesives applied during manufacturing, reducing installation labor by 65% in high-volume production. For extreme environments, fluorosilicone-edge-sealed configurations maintain integrity at continuous 392°F while avoiding delamination. Custom compound formulations solve compatibility challenges like amine-induced stress cracking in refrigeration systems through specially developed stabilizer packages tested against ASHRAE standards.

Implementation Case Studies

Green Roofing Systems: Chicago's 35,000ft² commercial installation utilized 3mm rubber sheet roll membranes with reflective surface treatment, reducing building cooling loads by 23% while achieving 60-year projected service life through reinforced polyester scrim. Thermographic scans confirmed consistent thermal barrier performance across all seasons.

Chemical Processing Plant: A petrochemical facility upgraded gasketing materials to reinforced EPDM rolls (1.5mm thickness with PTFE film surface) to withstand methyl ethyl ketone exposure. Seal failures decreased from quarterly incidents to zero occurrences over three years, saving $180,000 annually in maintenance and downtime.

Automotive Testing: Dynamometer facility implemented 1mm rubber sheet roll isolation barriers to contain hydraulic fluids on test stands. The chemical-compatible formulation resisted degradation from automatic transmission fluid at 250°F, outperforming previous materials with 7x longer replacement cycles.

Long-Term Value in EPDM Roll Applications

With proper installation protocols including substrate preparation and compatible adhesives, roll of rubber sheet EPDM rubber delivers demonstrable cost savings through superior lifecycle performance. Maintenance records from industrial users confirm an 80% reduction in replacement frequency compared to SBR alternatives, with accelerated ROI calculations showing break-even within 18-24 months despite premium material costs. The critical combination of weather, temperature, and chemical resistance positions EPDM as the optimum choice where reliability cannot be compromised – particularly in 1mm rubber sheet roll applications where material efficiency provides budget flexibility.

Testing data consistently validates performance retention beyond 15-year service markers across roofing, automotive, and industrial sectors. Advancements in additive technologies continue extending application boundaries while sustainable manufacturing processes have reduced carbon footprints by 40% over the past decade. When specifying membrane systems, the intrinsic properties of professionally formulated EPDM rubber sheet rolls provide unmatched security against environmental degradation vectors that compromise inferior materials.

(roll of rubber sheet epdm rubber)

FAQS on roll of rubber sheet epdm rubber

Q: What is EPDM rubber sheet roll typically used for?

A: EPDM rubber sheet rolls are primarily used for waterproofing and sealing applications. They excel in roofing membranes due to excellent UV and weather resistance. Industrial gaskets and pond liners also utilize this durable material.

Q: What thicknesses are available for rolled EPDM rubber sheets?

A: Common thickness options include 1mm rubber sheet roll for lightweight sealing and 3mm rubber sheet roll for heavy-duty applications. Both sizes offer flexibility while accommodating different structural demands. Standard rolls maintain consistent thickness across lengths.

Q: Why choose EPDM over other rubber materials?

A: EPDM outperforms many rubbers in temperature resistance (-40°C to 150°C) and ozone protection. Its closed-cell structure prevents water absorption, ideal for outdoor exposure. Additionally, it's more cost-effective than silicone or neoprene alternatives.

Q: Can I install a 3mm EPDM rubber sheet roll myself?

A: Yes, 3mm rubber sheet rolls are flexible enough for DIY projects like shed roofs or playground surfaces. Use compatible EPDM adhesive and seam tape for watertight joints. Always clean and prepare the substrate thoroughly before installation.

Q: How do I store unused EPDM roll rubber sheets?

A: Store rolls vertically in cool, dry spaces away from sunlight. Avoid contact with oils or solvents that could degrade the material. Keep in original packaging until use to prevent deformation or surface contamination.