Dez . 06, 2024 21:14 Back to list

epdm rubber spec sheet

Understanding EPDM Rubber Specifications

EPDM (Ethylene Propylene Diene Monomer) rubber is a popular synthetic elastomer known for its excellent weather resistance, ozone resistance, and overall durability. It's widely used across various industries including automotive, construction, and consumer products due to its versatile properties. This article provides a comprehensive overview of EPDM rubber specifications and highlights its applications and advantages.

Chemical Composition and Structure

EPDM rubber is composed of ethylene, propylene, and a diene component. The unique combination of these materials results in a rubber that exhibits superior properties compared to other elastomers. The diene component, often a small fraction of the overall composition, is critical as it allows for cross-linking during the vulcanization process, enhancing the rubber's strength and elasticity.

Key Properties

1. Weather Resistance EPDM is renowned for its ability to withstand extreme weather conditions, including sunlight, rain, and temperature fluctuations. This makes it an ideal choice for outdoor applications where exposure to the elements is a concern.

2. Ozone Resistance One of the most significant advantages of EPDM rubber is its outstanding ozone resistance. Ozone can cause many types of rubber to deteriorate over time, leading to cracking and loss of functionality. EPDM remains stable in the presence of ozone, ensuring longevity in various applications.

3. Temperature Range EPDM rubber can perform effectively in a wide temperature range—from approximately -40°F to 300°F (-40°C to 150°C). This thermal stability makes it suitable for high- and low-temperature applications alike.

4. Chemical Resistance EPDM rubber exhibits good resistance to many chemicals, including alkalis and acids. However, it is not recommended for use with petroleum-based oils and solvents, giving it a niche role in environments where such substances are not present.

epdm rubber spec sheet

5. Electrical Insulation EPDM is also an excellent electrical insulator, making it suitable for applications in the electrical industry, including cables and wires.

Applications

EPDM rubber is utilized in a plethora of applications due to its advantageous properties. Common uses include

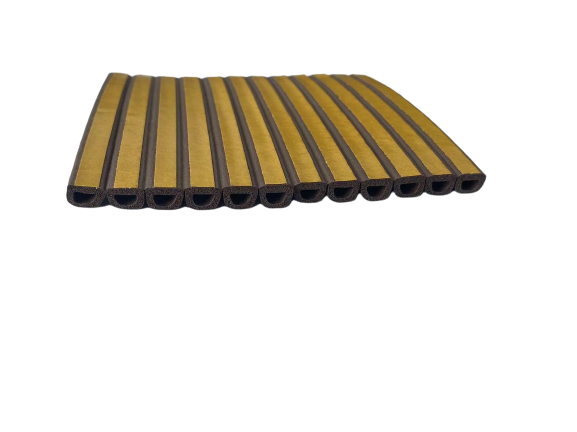

- Automotive Seals and Gaskets EPDM is widely used for weather stripping, seals, and gaskets in vehicles. Its resistance to weathering and ozone ensures that these automotive components maintain their integrity over time.

- Roofing Membranes In the construction industry, EPDM is frequently employed in roofing systems due to its waterproof characteristics and UV resistance. It helps in maintaining energy efficiency while providing a durable protective layer.

- Hoses and Belts EPDM's flexibility and elasticity make it ideal for manufacturing hoses, belts, and tubing used in various machinery and vehicles.

- Consumer Products Various consumer products, including toys and home goods, incorporate EPDM due to its non-toxic nature and resistance to aging.

Conclusion

In summary, EPDM rubber is a robust and versatile material that offers exceptional performance across a wide array of applications. Its resistance to weather, ozone, and temperature extremes, combined with good chemical stability, makes it a preferred choice in many industries. When looking for rubber solutions that endure the test of time and environmental factors, EPDM stands out as a top contender. Understanding the specifications and properties of EPDM can significantly enhance the design and longevity of products in which it is utilized. Whether in automotive, construction, or consumer goods, EPDM rubber continues to play a crucial role in delivering performance and reliability.