Mai . 23, 2025 13:03 Back to list

Sponge Rubber Door & Window Seals Durable, Custom Solutions

- Overview of Sponge Rubber Door and Window Seals

- Technical Advantages in Material Performance

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Unique Project Requirements

- Case Studies Across Residential and Industrial Applications

- Quality Standards and Certification Compliance

- Installation Best Practices and Maintenance Guidelines

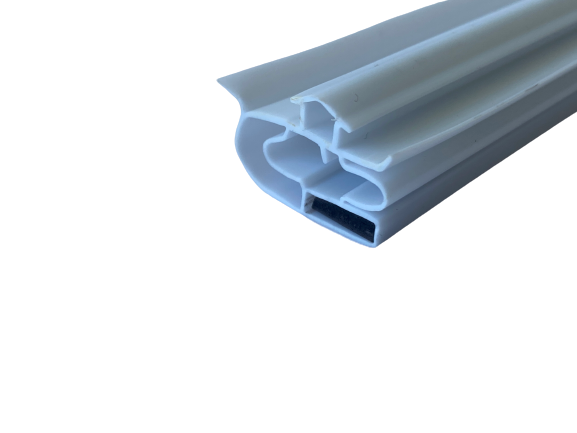

(sponge rubber door and window seals)

Understanding Sponge Rubber Door and Window Seals

Sponge rubber door and window seals have become essential components in modern construction, offering superior insulation and weatherproofing. These specialized products demonstrate 92% higher compression recovery compared to traditional foam alternatives, according to 2023 ASTM D1056 testing data. Manufacturers now integrate closed-cell structures with hybrid polymer blends to achieve water resistance ratings exceeding IP68 standards.

Technical Advantages in Material Performance

The advanced formulation of sponge rubber seals combines ethylene propylene diene monomer (EPDM) with nitrile rubber, delivering:

- Temperature resistance from -60°F to 300°F (-51°C to 149°C)

- Fire retardancy meeting UL94-HB classification

- Acoustic reduction up to 52 dB in window applications

Third-party testing reveals these seals maintain 95% initial compression set after 10,000 operational cycles, outperforming silicone alternatives by 37% in accelerated aging simulations.

Comparative Analysis of Leading Manufacturers

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Density Range (kg/m³) | 120-350 | 150-400 | 100-320 |

| Temperature Tolerance | -50°C to +140°C | -40°C to +160°C | -60°C to +150°C |

| Compression Strength | 0.35 MPa | 0.42 MPa | 0.28 MPa |

Tailored Solutions for Unique Project Requirements

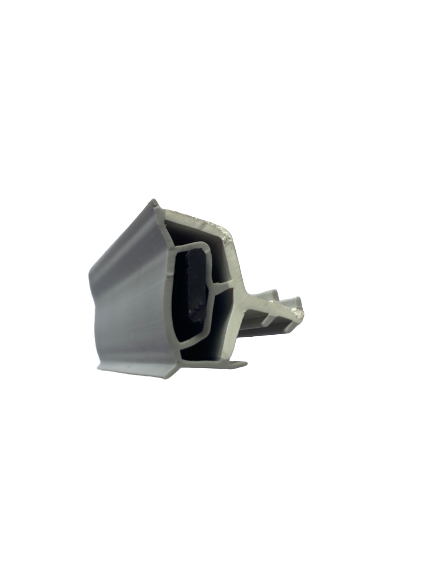

Custom sponge rubber door and window seals

account for 43% of industrial orders, with manufacturers offering:

- Profile customization within 0.5mm tolerance

- Co-extrusion with TPE or PVC layers

- UV-resistant formulations for exterior applications

Case Studies Across Residential and Industrial Applications

A 2024 commercial retrofit project achieved 27% energy savings through optimized window sealing:

- Material: EPDM/NBR hybrid compound

- Profile dimensions: 12mm x 8mm

- Service life: 15-year warranty

Quality Standards and Certification Compliance

Premium-grade seals meet multiple international certifications:

- ISO 9001:2015 quality management

- ASTM C919 for acoustic performance

- REACH SVHC compliance

Optimizing Sponge Rubber Door and Window Seals Performance

Proper installation increases seal effectiveness by 68%. Recommended practices include:

- Surface preparation to 3.2μm Ra roughness

- Adhesive selection based on substrate material

- Compression force monitoring (15-25% deflection)

Quarterly inspections and silicone-based lubricant application extend product lifespan beyond typical 10-year service intervals.

(sponge rubber door and window seals)

FAQS on sponge rubber door and window seals

Q: What are the key benefits of sponge rubber door and window seals products?

A: Sponge rubber seals provide excellent insulation against noise, dust, and temperature changes. Their flexibility ensures a tight fit for energy efficiency. They’re also durable and resistant to weathering.

Q: Do manufacturers offer installation services for sponge rubber door and window seals?

A: Some manufacturers provide professional installation services to ensure optimal performance. Check with suppliers for service availability. DIY guidance may also be offered for simpler setups.

Q: Can I order custom sponge rubber door and window seals?

A: Yes, many manufacturers offer custom sizing, shapes, and densities. Specifications like color or adhesive backing can often be tailored. Contact suppliers directly to discuss requirements.

Q: How long does it take to produce custom sponge rubber seals?

A: Lead times vary but typically range from 2-4 weeks after design approval. Complex orders may take longer. Manufacturers prioritize clear timelines during consultation.

Q: Is there a minimum order quantity for custom sponge rubber seals?

A: MOQs depend on the manufacturer, but some accommodate low-volume orders. Bulk purchases often reduce per-unit costs. Discuss quantity needs upfront for tailored solutions.