Ноя . 08, 2024 09:32 Back to list

Customizable Marine Fender Rubber Sealing Strip Supplier for Enhanced Protection and Durability

Customizable Marine Fender Rubber Sealing Strip Manufacturer

In the realm of maritime operations, ensuring the safety and efficiency of docking and berthing processes is of utmost importance. One crucial component that plays a significant role in this regard is the marine fender rubber sealing strip. These specialized products act as protective barriers between vessels and docking structures, absorbing impacts and preventing damage. A leading manufacturer of customizable marine fender rubber sealing strips has emerged as a key player in meeting the diverse needs of the maritime industry.

Understanding Marine Fender Rubber Sealing Strips

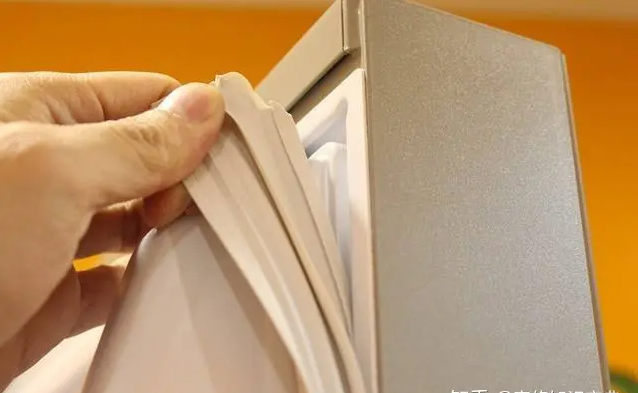

Marine fender rubber sealing strips are essential in various marine applications. They are designed to cushion impacts between boats and docks, reducing wear and tear on both the vessels and the docks while enhancing safety during mooring operations. These strips are made from high-quality rubber materials that offer excellent resilience and durability, ensuring they can withstand the harsh marine environment.

The customization of these sealing strips is vital for various reasons. Different vessels have unique shapes and sizes, and their docking structures can vary significantly. A one-size-fits-all approach often falls short, making it imperative for manufacturers to offer customizable solutions to meet the specific needs of their clients.

The Importance of Customization

Customizable marine fender rubber sealing strips provide numerous advantages. Firstly, they ensure perfect fitting and alignment, minimizing gaps that could lead to potential damages during docking. A well-fitted sealing strip provides a more effective impact cushion, enhancing safety and protecting both vessels and terminals.

Additionally, customization allows manufacturers to incorporate specific features as required by their clients. This could include varying the density, hardness, and profile of the rubber used in the sealing strips, tailoring them to handle different levels of impact and environmental conditions. For example, vessels that frequently dock in rougher seas may require thicker and denser strips to absorb greater kinetic energy.

Advanced Manufacturing Techniques

Leading manufacturers leverage advanced manufacturing techniques to produce high-quality marine fender rubber sealing strips. This includes the use of state-of-the-art machinery and technology that guarantees precision and consistency across all products. Computer-aided design (CAD) allows engineers to create highly detailed models of sealing strips, which can then be adjusted to fit specific requirements.

customizable marine fender rubber sealing strip manufacturer

Moreover, the use of high-performance rubber compounds contributes to longer-lasting products. The combination of durability, flexibility, and resistance to aging from UV light and saline water makes these sealing strips highly effective in various marine environments.

Commitment to Quality and Safety

A reputable manufacturer prioritizes quality assurance at every stage of production. Rigorous testing procedures are implemented to ensure that the rubber sealing strips meet industry standards and regulations. This involves subjecting the strips to various stress tests and environmental simulations to verify their performance under extreme conditions.

Safety is a critical factor in maritime operations, and using substandard materials can lead to accidents that have severe consequences. Therefore, manufacturers should be transparent about their sourcing of materials and emphasize their commitment to using only the highest quality rubber.

Customer-Centric Approach

Apart from customization and quality, a customer-centric approach is vital for a successful manufacturer. Providing excellent customer service, including consultative support throughout the design and ordering process, can enhance the overall client experience. Listening to customer feedback and adapting products accordingly demonstrates a manufacturer’s commitment to meeting the changing needs of the maritime industry.

Sustainability in Manufacturing

With the increased emphasis on sustainability, many manufacturers are seeking ways to incorporate eco-friendly practices into their operations. Utilizing recyclable materials for production and adopting sustainable manufacturing processes can appeal to environmentally-conscious customers and enhance a manufacturer’s reputation.

Conclusion

In summary, customizable marine fender rubber sealing strips are a pivotal component in ensuring safe maritime operations. A manufacturer that prioritizes quality, customization, and customer satisfaction can significantly influence the safety and efficiency of docking processes. As the maritime industry continues to evolve, investing in high-quality, tailored solutions will be essential for businesses seeking to maintain competitiveness and safety on the water. Emphasizing sustainable practices will also pave the way for a brighter, more responsible future in marine operations.