Янв . 14, 2025 10:55 Back to list

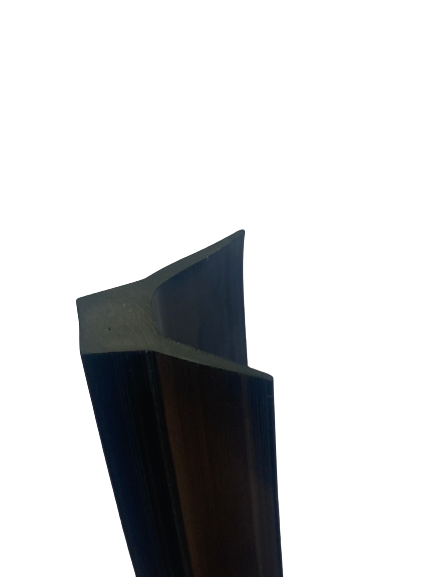

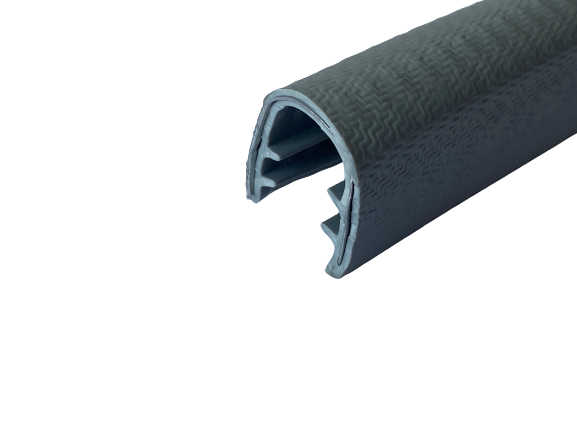

epdm car window rubber seal

Navigating the world of industrial materials, specifically within the realm of elastomers, EPDM rubber sheets are gaining significant traction due to their exceptional resilience and versatile applications. As businesses increasingly seek durable yet cost-effective solutions, wholesale EPDM rubber sheets present a perfect opportunity for industries ranging from automotive to construction.

Trustworthiness in any industrial product is predicated not only on quality but also on supplier credibility. Engaging with reputable wholesalers who maintain robust quality control processes is indispensable. ISO certifications and compliance with international standards, such as ASTM, act as benchmarks of quality assurance. This is especially critical in industries where safety and performance efficacy cannot be compromised. Furthermore, authoritativeness in the market often correlates with innovation. Leading EPDM sheet manufacturers and wholesalers are those who continually evolve their product line, integrating the latest technological advancements to enhance product strength and versatility. For example, recent innovations have led to the development of reinforced EPDM sheets that combine traditional durability with enhanced tear resistance. Leveraging my professional background, I continually advise businesses to prioritize a cost-benefit analysis in material selection. While EPDM sheets might appear to carry a higher upfront cost compared to alternatives like neoprene or SBR, their longevity and minimal maintenance requirements often translate into significant savings over the product lifecycle. This economic advantage underscores the need for a holistic procurement strategy that looks beyond immediate expenses. Ultimately, the paramount consideration in EPDM sheet procurement is ensuring alignment between product capability and application demand. The strategic value of investing in high-grade, durable materials cannot be overstated, particularly within sectors reliant on continuous, reliable operation. For businesses keen on optimizing material efficiency, wholesale EPDM rubber sheets unequivocally offer a ubiquitously endorsed solution grounded in empirical success and expert validation.

Trustworthiness in any industrial product is predicated not only on quality but also on supplier credibility. Engaging with reputable wholesalers who maintain robust quality control processes is indispensable. ISO certifications and compliance with international standards, such as ASTM, act as benchmarks of quality assurance. This is especially critical in industries where safety and performance efficacy cannot be compromised. Furthermore, authoritativeness in the market often correlates with innovation. Leading EPDM sheet manufacturers and wholesalers are those who continually evolve their product line, integrating the latest technological advancements to enhance product strength and versatility. For example, recent innovations have led to the development of reinforced EPDM sheets that combine traditional durability with enhanced tear resistance. Leveraging my professional background, I continually advise businesses to prioritize a cost-benefit analysis in material selection. While EPDM sheets might appear to carry a higher upfront cost compared to alternatives like neoprene or SBR, their longevity and minimal maintenance requirements often translate into significant savings over the product lifecycle. This economic advantage underscores the need for a holistic procurement strategy that looks beyond immediate expenses. Ultimately, the paramount consideration in EPDM sheet procurement is ensuring alignment between product capability and application demand. The strategic value of investing in high-grade, durable materials cannot be overstated, particularly within sectors reliant on continuous, reliable operation. For businesses keen on optimizing material efficiency, wholesale EPDM rubber sheets unequivocally offer a ubiquitously endorsed solution grounded in empirical success and expert validation.

Next:

Prev: