Окт . 15, 2024 11:23 Back to list

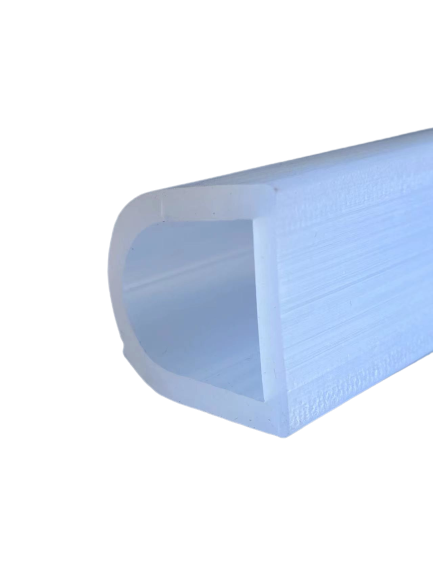

odm silicone rubber seal strip for oven door

The Importance of ODM Silicone Rubber Seal Strips for Oven Doors

In the realm of kitchen appliances, the efficiency and safety of ovens are paramount. One critical component that often goes unnoticed is the silicone rubber seal strip. Designed specifically for oven doors, these seal strips play a vital role in ensuring optimal performance and energy efficiency. With the growing trend of Original Design Manufacturing (ODM), silicone rubber seal strips have become customized products that cater to the specific needs of different oven designs and brands.

Silicone rubber seal strips are made from high-quality silicone that can withstand extreme temperatures, ranging from -60°C to 250°C (-76°F to 482°F). This property makes them ideal for use in ovens, where heat retention is essential for cooking and baking. The primary function of these seal strips is to prevent heat from escaping the oven, which not only enhances cooking efficiency but also helps in reducing energy costs. By maintaining a consistent internal temperature, silicone rubber seals contribute significantly to more even cooking results, ultimately improving the quality of the food prepared.

Another key advantage of silicone rubber seal strips is their durability and flexibility. Unlike traditional rubber seals, which may degrade over time due to high temperatures and chemical exposure, silicone exhibits excellent resistance to aging, weathering, and various chemicals. This level of durability translates to a longer lifespan for the seal, requiring less frequent replacements and minimizing maintenance costs for both manufacturers and end-users.

odm silicone rubber seal strip for oven door

Custom ODM solutions in silicone rubber seal manufacturing allow for precise specifications tailored to individual oven designs. This customization process ensures that the seals fit perfectly, creating an airtight barrier that prevents leaks of hot air or steam. By working with ODM manufacturers, companies can develop seal strips that not only match the dimensions of their oven doors but also reflect the aesthetic preferences and branding of their products. This gives them a competitive edge in the market, as consumers increasingly seek products that are not only functional but also visually appealing.

Moreover, the application of advanced technology in the production of silicone rubber seal strips enhances their performance attributes. Features such as anti-adhesive properties, enhanced resistance to UV light, and improved elasticity can be incorporated into the design based on the specific requirements of the manufacturer. This level of innovation not only boosts the overall functionality of the oven but also aligns with the industry trend of producing high-performance kitchen appliances.

In addition to performance and customization, the environmental impact of silicone rubber seal strips is worth mentioning. Silicone is a more environmentally friendly option compared to many other materials, as it can be recycled and does not produce harmful by-products during manufacturing. As sustainability becomes an increasingly important factor for consumers, offering silicone rubber seal strips can position a brand as responsible and eco-conscious.

In summary, ODM silicone rubber seal strips for oven doors are indispensable components that enhance appliance efficiency, durability, and aesthetics. Their ability to withstand extreme temperatures, coupled with customizable design options, makes them a favorite among manufacturers and consumers alike. As the kitchen appliance market continues to evolve, the significance of high-quality, tailored silicone seal solutions will only grow, paving the way for better cooking experiences and energy savings in households worldwide.