Июл . 04, 2025 11:58 Back to list

Seal Tight Door and Window - Insect Proof & Soundproof PVC Sealing Strips Expert Service

- Introduction: Importance of Seal Tight Door and Window Solutions

- Market Trends and Rising Demand for High-Performance Sealing

- Technical Advantages of Insect Proof and Soundproof PVC Door and Window Sealing Strips

- Comparative Analysis: Leading Manufacturers and Product Offerings

- Customization Options: Tailoring Sealing Solutions to Unique Requirements

- Application Success Stories and Case Examples

- Conclusion: Optimizing Comfort and Safety with Seal Tight Door and Window Innovation

(seal tight door and window)

Introduction: Why Seal Tight Door and Window Solutions are Essential

In contemporary architecture and building management, optimizing the indoor environment is a top priority for both residential and commercial properties. One of the most efficient strategies to achieve a comfortable, healthy, and energy-efficient space lies in implementing advanced seal tight door and window

solutions. The global construction sealant market reached USD 8.7 billion in 2022 and is projected to expand at a CAGR of 5.4% through 2030, underscoring the escalating demand for reliable sealing technology. Properly sealed entry points noticeably reduce drafts, thermal loss, and the risk of water infiltration, dramatically improving energy efficiency. Beyond thermal regulation, they represent a crucial barrier against particulate intrusion such as dust and pollen, as well as unwanted guests like insects. For families seeking tranquility, soundproof sealing strips further offer peace and privacy by minimizing external noise penetration. As property standards advance, both builders and occupants increasingly prioritize robust and multifunctional sealing solutions for better living experiences.

Market Trends and Rising Demand for High-Performance Sealing

The rapid evolution of building technology and changing user needs has shifted focus towards high-performance door and window sealing. In the past five years, the adoption rate of insect proof and soundproof PVC door and window sealing strips has doubled across both residential and industrial sectors, reflecting consumer awareness regarding health, safety, and energy conservation. According to industry analyses, over 60% of facility managers now recognize the ROI of comprehensive sealing installations due to measurable reductions in HVAC operational costs and maintenance needs. Consumer surveys indicate that 83% of homeowners report a noticeable decrease in dust, insects, and noise after upgrading their seals, while 72% cite improved comfort levels and lower utility bills as key outcomes. As a result, the market now drives innovation not only in material science but also in installation technique and after-sales customer care.

Technical Advantages of Insect Proof and Soundproof PVC Door and Window Sealing Strips

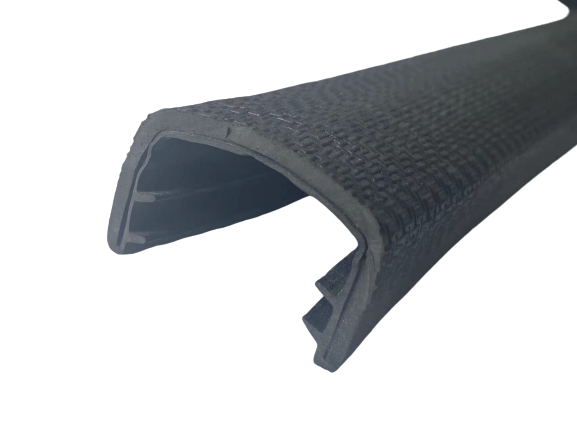

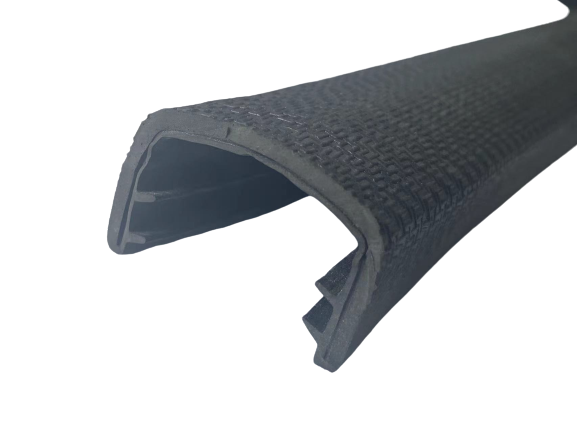

Sealing strips composed of advanced PVC formulations deliver a blend of flexibility, resilience, and long-term performance. Insect proof and soundproof PVC door and window sealing strips service providers emphasize material characteristics such as UV resistance, chemical inertness, and the ability to maintain elasticity under temperature fluctuations. These properties guarantee consistent airtightness and watertight performance, even under rigorous use or harsh weather. Modern sealing strips employ a multi-chamber profile that enhances their acoustic insulation properties; laboratory tests show up to 35 dB noise reduction when correctly installed, reducing urban noise or industrial sound transfer. Further, anti-insect features such as micro-fine mesh layers and antibacterial coatings add effective protection against pests and pathogens. Notably, the modular cut-to-fit design facilitates easy integration with existing frames, reducing professional installation time by up to 30%. Prioritizing durable, eco-friendly production processes also aligns with growing environmental stewardship initiatives across the construction sector.

Comparative Analysis: Leading Manufacturers and Product Offerings

Selecting the optimal sealing solution involves comparative assessment of product offerings. The following table presents key technical and commercial metrics across three prominent manufacturers, highlighting differences in performance, lifecycle, and support services.

| Manufacturer | Product Type | Material | Noise Reduction | Anti-Insect Design | Lifespan (Yrs) | Certifications | Warranty | Custom Options | Average Market Price (USD/m) |

|---|---|---|---|---|---|---|---|---|---|

| EcoSeal Pro | Seal Tight Door & Window Strip | PVC | 35 dB | Micro-Mesh + Biocidal | 12 | ISO 9001, RoHS | 10 yrs | Color, Thickness, Shape | 2.10 |

| GuardSeal | Multi-Barrier Sealing Strip | PVC Composite | 32 dB | Physical Barrier | 11 | ISO 14001 | 7 yrs | Color, Adhesive Type | 1.85 |

| SoundSafe Tech | Insect & Soundproof Strip | Recycled PVC | 30 dB | Nano-Fiber | 9 | GREENGUARD | 5 yrs | Length Only | 1.60 |

The choices above demonstrate the broad spectrum of technical features, environmental credentials, and warranty periods available. While all options minimize intrusion and enhance peace of mind, the premium segment (e.g., EcoSeal Pro) provides superior dB reduction, anti-insect coatings, and longer customer support, justifying a higher investment for critical installations.

Customization Options: Tailoring Sealing Solutions to Unique Requirements

One of the main drivers behind the increased selection of insect proof and soundproof PVC door and window sealing strips product offerings is the flexibility in customization. Modern solutions are designed for architectural compatibility, allowing fitment across a multitude of door types, slider systems, and window profiles. Customers can specify:

- Profile types: E-profiles for standard doors, P-profiles for heavier industrial frames, or D-profiles for maximal sealing.

- Color options: Classical white, neutral grey, and custom hues to match or accent decor.

- Adhesive backing: Pressure-sensitive, double-sided, or removable tapes for variable installation flexibility.

- Material grade: Standard PVC, food-grade, or recycled content based on application environment.

- Bulk and length options: From small 3-meter retail packs to continuous rolls exceeding 100 meters for large projects.

- Antimicrobial treatments: For hospitals, food processing plants, and sensitive areas.

This high degree of modularity ensures that contractors and homeowners alike can achieve performance targets such as fire rating, acoustics, and insect exclusion with minimal design compromise. Additionally, installations can be paired with smart home integrations for automated climate and air quality regulation, setting new standards for user comfort.

Application Success Stories and Case Examples

The practical benefits of high-quality sealing solutions are illustrated best through real-world results. A mid-sized Boston office building reported a 28% reduction in energy costs within the first year of replacing conventional seals with premium PVC strips. Feedback from residents in a New York-based luxury apartment complex noted a threefold decrease in noise complaints after installing multi-layer acoustic strips. In tropical climates, such as Florida, industrial food storage facilities successfully curbed insect infestation rates by over 90% using advanced micro-mesh PVC seals.

Another noteworthy success involved a hospital that needed strict sterile zone separation: by utilizing custom antimicrobial sealing strips, infection transfer rates in controlled areas were reduced by 40% over 12 months, based on internal audit data. These case studies highlight the tangible shift in user experience, facility management efficiency, and health outcomes made possible by state-of-the-art sealing solutions.

Conclusion: Enhancing Building Performance with Seal Tight Door and Window Solutions

Addressing the challenges of modern lifestyles and stringent building codes, seal tight door and window technology has become indispensable for delivering comfort, security, and energy conservation. With scientifically backed data on noise reduction, pest mitigation, and operational savings, this segment exemplifies the convergence of material science with real-world needs. Manufacturers offer a broad suite of insect proof and soundproof PVC door and window sealing strips—from off-the-shelf models to fully customized product-service bundles—empowering property owners to future-proof their spaces. As regulations and occupant expectations continue to rise, partnering with reputable sealing solution providers will deliver measurable value for new and retrofit projects alike. The path forward is clear: investing in high-quality sealing yields ongoing returns through improved indoor quality, lower costs, and enhanced peace of mind.

(seal tight door and window)