Ara . 27, 2024 06:10 Back to list

customizable silicone rubber sealing strip for refrigerator doors factories

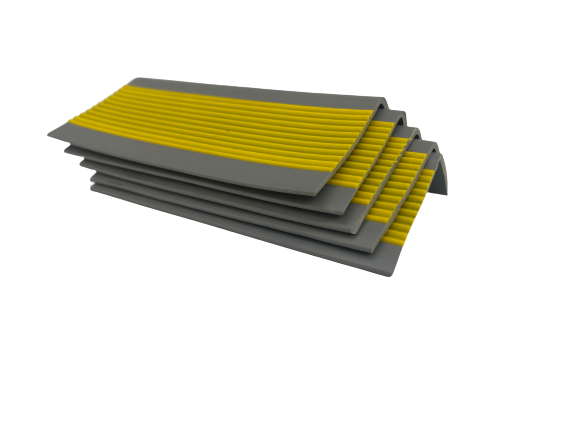

Customizable Silicone Rubber Sealing Strips for Refrigerator Doors

In today’s world, technology has made significant strides in enhancing the efficiency and functionality of household appliances, particularly refrigerators. Among the critical components that contribute to the optimal operation of refrigerators are sealing strips. Customizable silicone rubber sealing strips have emerged as a preferred choice for refrigerator door manufacturing, providing excellent insulation, durability, and versatility. This article will examine the importance of these sealing strips, the benefits of customization, and the role of factories in this innovative solution.

Importance of Sealing Strips

Sealing strips play a vital role in maintaining the performance of refrigerators. They create an airtight seal around the door, preventing cold air from escaping while keeping warm air out. This not only helps in maintaining the desired temperature inside the refrigerator but also contributes to energy efficiency. When refrigerator doors are properly sealed, the compressor does not have to work as hard to maintain the required temperature, leading to lower energy consumption and reduced electricity bills.

Moreover, efficient sealing minimizes the risk of moisture buildup, which can lead to mold growth and unpleasant odors. The quality of the sealing strip directly affects these factors, making it crucial for refrigerator manufacturers to choose the right materials and designs.

Benefits of Silicone Rubber

Silicone rubber has become a popular material for sealing strips due to its unique properties. Unlike traditional materials such as foam or neoprene, silicone rubber offers exceptional flexibility, resilience, and longevity. One of the standout characteristics of silicone is its ability to withstand extreme temperatures, making it ideal for use in refrigeration systems.

Additionally, silicone rubber is known for its resistance to aging, UV degradation, and moisture. This means that silicone sealing strips maintain their integrity over time, providing long-lasting performance without becoming brittle or cracking. Furthermore, silicone is non-toxic and environmentally friendly, which is increasingly important for consumers seeking sustainable product options.

Customization Tailoring Solutions to Fit

customizable silicone rubber sealing strip for refrigerator doors factories

One of the key advantages of working with silicone rubber sealing strips is the ability to customize them to meet specific requirements. Customizable sealing strips can be manufactured in various shapes, sizes, colors, and thicknesses, allowing refrigerator manufacturers to design products that perfectly fit their designs and meet consumer needs.

Customization extends beyond physical attributes; manufacturers can also opt for specific levels of flexibility or hardness based on the intended use of the refrigerator. For instance, a commercial refrigerator may require a more robust sealing solution due to its frequent opening and closing, while a home refrigerator could benefit from a softer, quieter sealing strip.

By employing advanced manufacturing techniques, factories can create sealing strips that meet precise dimensions and performance specifications. This level of customization ensures that manufacturers can deliver high-quality refrigerators that enhance user satisfaction and operational efficiency.

The Role of Factories

The production of customizable silicone rubber sealing strips is typically carried out in specialized factories equipped with cutting-edge technology. These factories employ skilled professionals who understand the intricacies of rubber manufacturing and can ensure that the highest standards are met.

Factories not only focus on the production process but also engage in extensive quality control measures to ensure that each sealing strip performs as intended. Using advanced testing protocols, manufacturers can simulate real-world conditions to test the durability, elasticity, and temperature resistance of their sealing strips.

Moreover, as consumer demands evolve, factories are also investing in research and development to innovate new designs and materials. This proactive approach ensures that manufacturers can stay ahead of market trends and deliver sealing solutions that meet the growing expectations of consumers.

Conclusion

Customizable silicone rubber sealing strips have fundamentally transformed the way refrigerator manufacturers enhance their products. By providing superior insulation, energy efficiency, and longevity, these sealing solutions contribute significantly to the overall functionality and sustainability of refrigerators. As the demand for innovative and customizable products continues to rise, the collaboration between manufacturers and factories will play a crucial role in driving advancements in sealing technology, ultimately improving the user experience in homes and businesses alike.