Ara . 09, 2024 20:42 Back to list

EPDM Rubber Sheet Production and Quality Standards for Optimal Performance

Understanding EPDM Rubber Sheet Manufacturers

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile elastomer widely employed in various industries due to its outstanding properties. These include excellent weather resistance, UV stability, ozone resistance, and a good temperature range, making it an ideal choice for various applications. Consequently, the demand for EPDM rubber sheets has surged, leading to a growing market for manufacturers specializing in this type of rubber product.

What is EPDM Rubber?

EPDM rubber is a synthetic rubber that consists of ethylene, propylene, and a diene monomer. The unique chemical composition of EPDM gives it the ability to withstand extreme weather conditions, making it an ideal option for outdoor applications. With a high degree of elasticity and excellent aging resistance, EPDM is commonly used in roofing membranes, seals, gaskets, and even automotive components.

Applications of EPDM Rubber Sheets

EPDM rubber sheets are commonly used in various industries due to their exceptional durability and reliability. Some prominent applications include

1. Construction Industry EPDM rubber sheets are used in roofing materials, waterproofing membranes, and expansion joints. They provide excellent insulation and protection from weather elements.

2. Automotive Industry EPDM is used in weather stripping, gaskets, and seals to ensure vehicles are insulated from external conditions, providing comfort and safety for passengers.

3. Electrical Industry The insulating properties of EPDM rubber make it ideal for electrical applications. It is used in cable insulation and components that require resistance to heat and weather.

4. Manufacturing EPDM rubber sheets are utilized in various manufacturing settings, including conveyor belts, vibration dampening, and seals where exposure to different chemicals may occur.

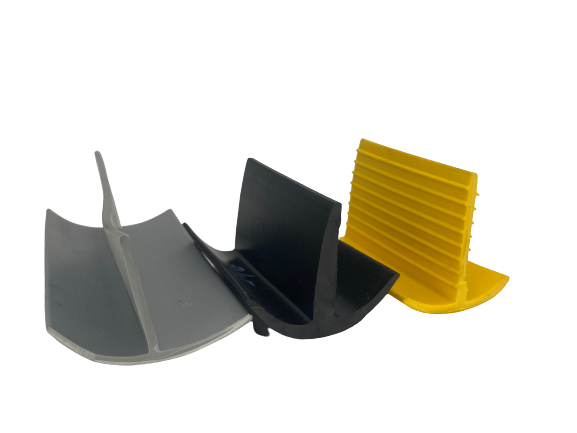

epdm rubber sheet manufacturer

Choosing the Right EPDM Rubber Sheet Manufacturer

With an increasing number of EPDM rubber sheet manufacturers in the market, selecting the right supplier can be daunting. Here are a few key factors to consider

1. Quality Assurance It is crucial to choose a manufacturer that adheres to strict quality control measures. Look for certifications such as ISO 9001, which confirms the manufacturer’s commitment to quality in their production processes.

2. Customization Options Depending on your specific needs, you may require custom sizes, thicknesses, or formulations. A good manufacturer should offer tailored solutions to meet your requirements.

3. Experience and Reputation Manufacturers with a long-standing presence in the industry often have a wealth of knowledge and expertise. Look for companies with a strong reputation, positive customer feedback, and a portfolio of successful projects.

4. Sustainability Focus As environmental concerns grow, it’s increasingly important to choose manufacturers that adopt sustainable practices in their production processes, such as recycling or using eco-friendly materials.

5. Customer Support Effective communication and support are key indicators of a quality manufacturer. Consider companies that are responsive and willing to assist you before and after your purchase.

Conclusion

The growing demand for EPDM rubber sheets has led to an increase in manufacturers in the industry, providing a plethora of options for businesses. When selecting an EPDM rubber sheet manufacturer, it is vital to assess quality, customization options, experience, sustainability practices, and customer support. By making informed decisions, businesses can ensure they source EPDM products that meet their specific needs while maintaining high standards of quality and performance. As industries continue to evolve, EPDM rubber sheets will remain an essential component in providing lasting durability and reliability across various applications.

In summary, understanding the landscape of EPDM rubber sheet manufacturers empowers businesses to make choices that enhance their operational efficiency, contribute to sustainability efforts, and ultimately lead to superior products that stand the test of time.