Kas . 13, 2024 21:45 Back to list

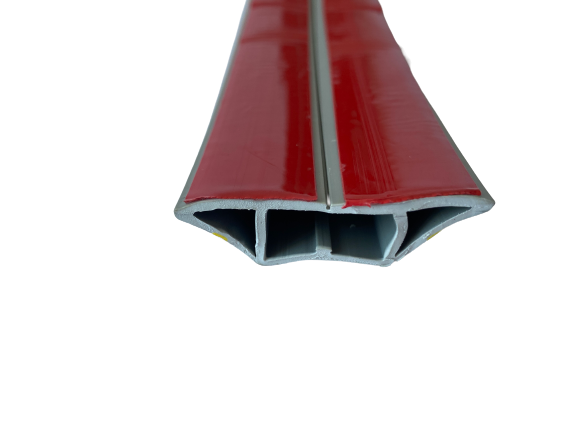

industrial rubber rolls

The Versatile World of Industrial Rubber Rolls

In the realm of industrial applications, the significance of rubber rolls cannot be overstated. These resilient and adaptable products play an integral role in various industries, including manufacturing, printing, packaging, and material handling. The utility of industrial rubber rolls lies in their ability to absorb shock, reduce friction, and provide a reliable surface for different operational needs. This article explores the many dimensions of industrial rubber rolls, including their composition, applications, and advantages.

Composition and Production

Industrial rubber rolls are typically made from a blend of natural and synthetic rubber materials. The choice of material significantly impacts the performance characteristics of the rolls, including their durability, flexibility, and heat resistance. Synthetic rubbers, such as neoprene or nitrile, are often utilized for specific applications that require specialized properties, such as resistance to oils, chemicals, or extreme temperatures.

The manufacturing process of rubber rolls involves several steps, including the mixing of raw materials, molding, and curing. Ensuring consistent quality during production is crucial, as any irregularities can lead to performance issues in the field. Modern manufacturing technologies enable producers to tailor the properties of rubber rolls to meet the specific demands of customers, ensuring optimal functionality in various applications.

Applications Across Industries

The versatility of industrial rubber rolls is demonstrated through their wide-ranging applications

1. Printing In the printing industry, rubber rolls serve as an essential component in various printing presses. They help in the transfer of ink to the substrate, ensuring even distribution and high-quality prints. The right type of rubber roll can enhance the print quality by reducing fuzzing and improving adherence to the surface.

2. Packaging Rubber rolls are integral to packaging operations, providing the necessary friction to facilitate the movement and alignment of products. They are often used in conveyor systems, ensuring smooth and efficient product handling throughout the packaging process. Their ability to withstand wear and tear enhances the longevity of packaging machinery.

3. Material Handling In warehouses and factories, rubber rolls are utilized in conveyor belts and rollers to move heavy loads with ease. Their shock-absorbing properties help reduce the impact on both the material being transported and the equipment itself. This not only maintains operational efficiency but also prolongs the lifespan of the machinery involved.

industrial rubber rolls

4. Textile Industry Rubber rolls also find application in the textile industry, where they are used in processes like calendering and finishing. The rolls provide a controlled environment for the treatment of fabrics, ensuring consistent quality and texture.

5. Food Processing In the food industry, rubber rolls must meet stringent hygiene standards. Many manufacturers produce food-grade rubber rolls that are resistant to contamination and easy to clean, making them ideal for use in food processing and packaging applications.

Advantages of Industrial Rubber Rolls

The benefits of using industrial rubber rolls are numerous

- Durability Industrial rubber rolls are designed to withstand rigorous use and harsh conditions, ensuring a long service life. Their resistance to wear and tear makes them a cost-effective investment for businesses.

- Flexibility The ability to adapt to various shapes and sizes allows rubber rolls to be customized for specific applications, providing tailored solutions to meet unique operational needs.

- Reduced Friction The rubber surface provides an excellent grip, minimizing slippage and enhancing overall efficiency during material handling or processing tasks.

- Noise Reduction Rubber rolls can help in dampening noise, creating a quieter work environment, which is particularly advantageous in settings where noise levels are critical.

Conclusion

In summary, industrial rubber rolls are indispensable components across a multitude of sectors, providing efficiency, reliability, and adaptability. As industries continue to evolve and innovate, the demand for high-quality, specialized rubber rolls will only increase. Manufacturers are likely to explore new materials and production techniques to meet these demands, further enhancing the versatility and functionality of industrial rubber rolls. This dynamic product will continue to play a crucial role in advancing industrial processes, ensuring smooth operations and high-quality outputs across various applications.

Next: