Ara . 29, 2024 04:06 Back to list

Alternative Sealing Strips for OEM Applications and Other Uses

The Importance of OEM Other Sealing Strips in Various Industries

In today’s competitive industrial landscape, manufacturers place significant emphasis on efficiency, quality, and reliability. Among the various components that contribute to these aspects, sealing strips play a crucial role. Specifically, Original Equipment Manufacturer (OEM) other sealing strips serve as essential components in a wide range of applications across multiple industries. Understanding their importance can help businesses appreciate how these seemingly small items can lead to substantial improvements in overall performance.

What are OEM Other Sealing Strips?

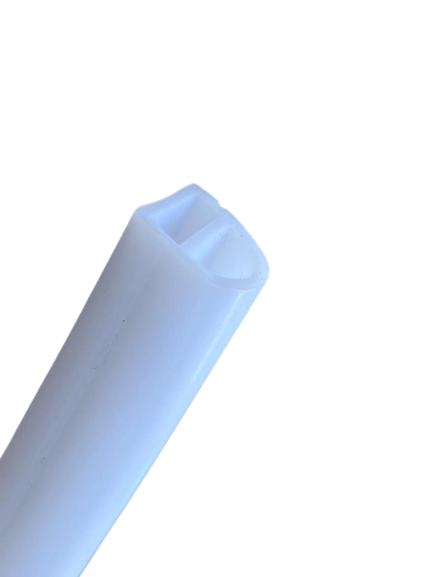

OEM sealing strips are produced by original equipment manufacturers and are designed to meet the specific requirements of the devices and machines they are intended for. Unlike generic or aftermarket sealing solutions, OEM sealing strips provide a perfect fit and compatibility, which is essential for optimal performance. These strips are made from various materials, including rubber, silicone, and foam, and are used to prevent the ingress of dust, moisture, and other contaminants. They can also dampen noise, reduce vibrations, and improve thermal insulation, making them indispensable in numerous applications.

Applications of OEM Other Sealing Strips

1. Automotive Industry Sealing strips in vehicles help maintain the integrity of the car's exterior and interior. They prevent water and air from entering cabins, ensuring passenger comfort while enhancing fuel efficiency. OEM sealing strips are crucial for maintaining the vehicle's aesthetic appeal and longevity.

2. Electronics In the electronics industry, sealing strips are used to protect sensitive components from moisture and dust. This is particularly vital for devices like smartphones, laptops, and other portable electronics, where prolonged exposure to environmental elements can lead to malfunctions. OEM sealing strips ensure that manufacturers meet safety standards and extend the product's lifespan.

3. Building and Construction In construction, sealing strips are applied in windows and doors to improve energy efficiency and comfort within buildings. They help to reduce heating and cooling costs by preventing drafts and heat losses. OEM options guarantee that these strips fit perfectly in their respective applications, contributing to tighter seals and better overall insulation.

4. Industrial Machinery Machinery often requires sealing strips to protect moving parts from contamination, which can lead to breakdowns and increased maintenance costs. OEM sealing strips ensure optimal performance and reliability of machines by keeping lubricants in and dirt out. They are vital in prolonging the life of equipment and enhancing productivity.

oem other sealing strips

Advantages of Using OEM Other Sealing Strips

Choosing OEM sealing strips over generic options offers numerous advantages

- Quality Assurance OEM products undergo rigorous testing to ensure they meet specific standards, offering peace of mind regarding their quality and reliability.

- Perfect Fit OEM sealing strips are designed for compatibility with particular applications, reducing the risk of failures due to improper sealing.

- Enhanced Performance With their superior design and materials, OEM sealing strips can perform better, leading to increased efficiency and reduced costs related to maintenance and repairs.

- Long-term Reliability Investing in OEM components generally results in lower replacement rates, ensuring that companies sustain their production schedules without unexpected downtime.

Conclusion

In conclusion, OEM other sealing strips are essential components across diverse sectors, playing a pivotal role in ensuring the efficient and reliable operation of equipment and products. By investing in these high-quality sealing solutions, businesses can not only enhance the performance of their products but also improve customer satisfaction and reduce long-term costs. As industries continue to evolve, the importance of OEM sealing strips remains a critical consideration for manufacturers looking to maintain a competitive edge.