Kas . 09, 2024 06:46 Back to list

Manufacturers of High-Quality Rubber Sealing Strips for Plastic Steel Doors and Windows

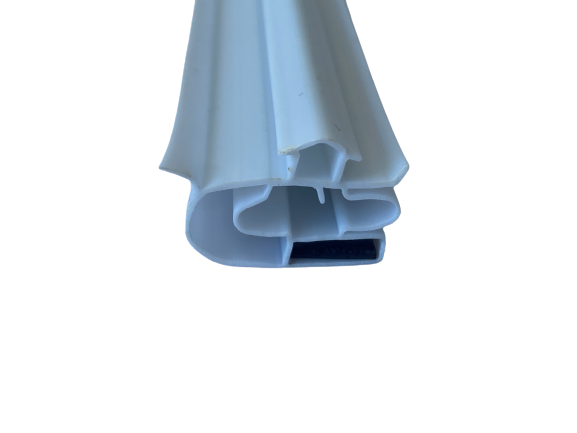

Exploring the World of Plastic Steel Door and Window Rubber Sealing Strip Factories

In today’s construction and manufacturing industries, the demand for durable and efficient sealing solutions is higher than ever. This is particularly true for plastic steel doors and windows, which are increasingly favored for their strength, insulation, and aesthetic appeal. At the heart of these products is a crucial component the rubber sealing strip. As the name implies, these sealing strips play a vital role in ensuring that doors and windows are airtight, weatherproof, and energy-efficient. This article delves into the role of plastic steel door and window rubber sealing strip factories in production, technology, and market dynamics.

The Importance of Sealing Strips

Rubber sealing strips are essential for various reasons. Firstly, they provide thermal insulation, preventing heat loss during colder months and keeping the interiors cool during summer. This energy efficiency not only enhances comfort but can also lead to significant savings on energy bills. Secondly, these seals are instrumental in noise reduction, providing a barrier against external sounds. Furthermore, they contribute to the overall longevity of the doors and windows by preventing water ingress, which can lead to mold and structural damage.

The Manufacturing Process

The manufacturing of rubber sealing strips involves several stages, from material selection to processing and quality control. Factories specializing in these products typically use a variety of synthetic and natural rubber compounds. These materials are selected based on their durability, elasticity, and resistance to environmental factors such as UV rays and extreme temperatures.

In the production process, raw materials undergo compounding, where they are mixed with additives to enhance performance characteristics. This is followed by molding, extrusion, or calendering, depending on the desired profile and application. Sophisticated machinery ensures precision, producing sealing strips that fit perfectly in their designated frames. The final product undergoes rigorous quality testing to ensure it meets industry standards for performance and safety.

Recent Innovations

plastic steel door and window rubber sealing strip factories

With advancements in technology, rubber sealing strip factories are continually innovating. New materials, such as thermoplastic elastomers (TPE) and silicone rubber, are being used to enhance the performance of sealing strips. These materials offer greater flexibility, resilience, and resistance to extreme weather conditions.

Moreover, manufacturers are now incorporating automated processes in their production line, which increases efficiency and reduces human error. Automated quality control systems equipped with sensors allow for real-time monitoring, ensuring that each sealing strip meets specific standards before it leaves the factory.

Market Trends and Global Demand

The global market for rubber sealing strips is expanding rapidly. With the booming construction industry and increasing awareness of energy conservation, more builders and homeowners are opting for plastic steel doors and windows equipped with high-quality sealing solutions. Additionally, the rise of environmentally-conscious consumers is driving the demand for sustainable and recyclable materials, prompting factories to adapt their offerings to cater to this demographic.

Regions such as Asia-Pacific, North America, and Europe are witnessing significant growth in this market, thanks to urbanization and infrastructure development. As construction standards evolve, the need for superior sealing solutions becomes paramount, and factories dedicated to producing these critical components are vital players in this evolving landscape.

Conclusion

Plastic steel door and window rubber sealing strip factories are the unsung heroes in the building materials industry. Their commitment to innovation, quality, and efficiency plays a crucial role in enhancing the performance of doors and windows, contributing to energy savings, comfort, and longevity in buildings. As technology evolves and market demands shift, these factories will continue to be essential in shaping the future of construction and architectural design.