Eki . 18, 2024 15:36 Back to list

PVC Shower Door Sealing Strip Suppliers for Enhanced Waterproofing Solutions

The Importance of PVC Sealing Strips for Shower Door Manufacturers

In the ever-evolving world of bathroom fixtures and fittings, one small yet essential component often overlooked is the PVC sealing strip. Shower doors are a focal point in modern bathrooms, and ensuring they function correctly and look great is paramount. For manufacturers of shower doors, the choice of sealing materials can significantly influence the product’s quality, durability, and customer satisfaction.

What are PVC Sealing Strips?

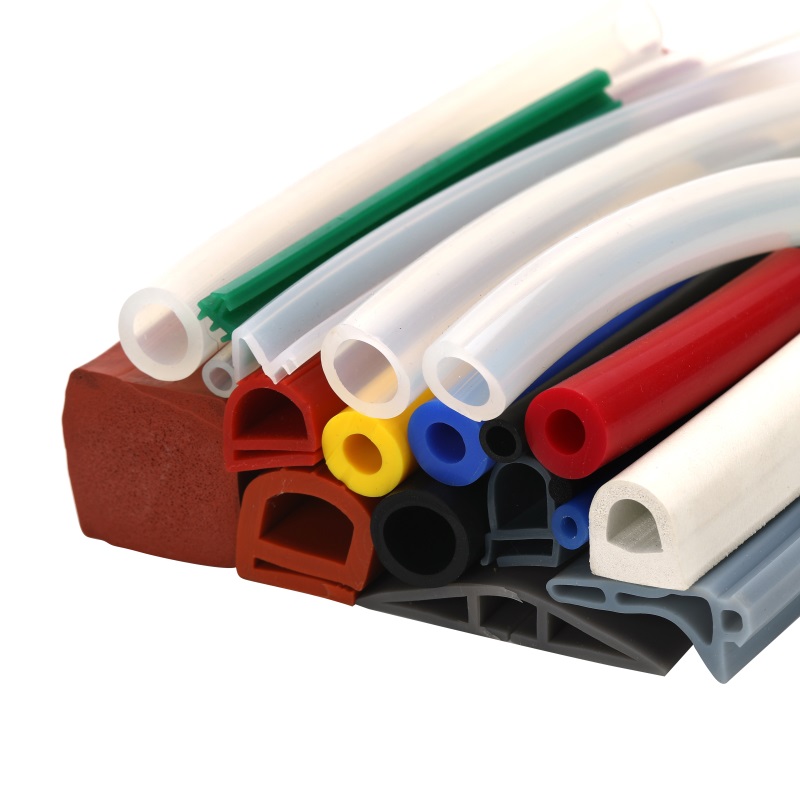

PVC sealing strips are flexible strips made from polyvinyl chloride (PVC), designed to create a watertight barrier between the shower door and the wall or floor. These strips are crucial in preventing water leakage, which can lead to mold growth, slippery floors, and other potential water damage. They come in various shapes and sizes to fit different types of shower doors—whether sliding, bi-fold, or hinged.

Benefits of Using PVC Sealing Strips

1. Water Resistance The primary function of PVC sealing strips is to provide a reliable water seal. This prevents water from escaping the shower enclosure, keeping the bathroom dry and minimizing the risk of damage.

2. Durability PVC is known for its resilience against wear and tear. PVC sealing strips resist damage from moisture, soap, and cleaning chemicals, ensuring a long lifespan. This durability translates to fewer repairs and replacements, making it a cost-effective choice for manufacturers.

3. Easy Installation These sealing strips are designed for DIY-friendly installation. Manufacturers can provide adhesive backing or offer easy-to-follow guidelines for installation, allowing consumers to fit them without professional assistance.

4. Versatility PVC sealing strips can be manufactured in various colors and designs to match different shower door aesthetics. This versatility allows manufacturers to cater to a wide range of consumer preferences while maintaining functionality.

pvc sealing strip for shower door manufacturers

5. Sound Insulation In addition to water sealing, PVC sealing strips can also provide sound insulation, reducing the noise of water hitting the shower floor or walls. This feature is especially appealing in homes where multiple family members share a bathroom.

Considerations for Manufacturers

When selecting PVC sealing strips for shower doors, manufacturers must consider several factors

- Quality of PVC The formulation of PVC can affect its longevity and performance. Using high-quality, UV-stabilized PVC can enhance durability, especially in areas with high humidity.

- Compatibility Designers must ensure that sealing strips are compatible with various types and designs of shower doors. A one-size-fits-all approach may not always work, so customization might be necessary.

- Environmental Impact As consumers become more environmentally conscious, manufacturers must consider the sustainability of their materials. Sourcing PVC from eco-friendly suppliers or exploring biodegradable alternatives can appeal to a broader market.

- Regulatory Compliance Manufacturers must ensure that their products comply with local building codes and regulations. This includes adhering to standards for materials used in wet areas to prevent mold and mildew.

Conclusion

In summary, PVC sealing strips play a pivotal role in the production of shower doors, enhancing their functionality, durability, and overall appeal. For manufacturers, investing in high-quality sealing strips not only improves the end product but also elevates customer satisfaction and trust. As the market for shower doors continues to expand, the importance of these unassuming yet vital components will only grow. By focusing on quality, innovation, and environmental responsibility, shower door manufacturers can position themselves as leaders in an increasingly competitive industry.