Ara . 12, 2024 04:47 Back to list

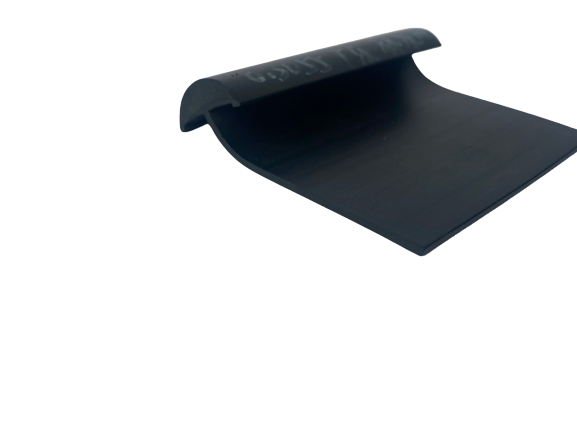

sbr rubber roll

Understanding SBR Rubber Rolls An Essential Material for Various Applications

Styrene-butadiene rubber (SBR) is a synthetic rubber that has become a cornerstone in many industrial applications. Known for its versatility, resilience, and cost-effectiveness, SBR is widely used in manufacturing a variety of products, including tires, gaskets, seals, and conveyor belts. Among the various forms in which SBR rubber is available, SBR rubber rolls stand out due to their practicality and adaptability across different sectors.

What is SBR Rubber?

SBR is a copolymer composed of styrene and butadiene, which are the two main monomers that make up this synthetic rubber. It was first developed in the 1930s and has since gained immense popularity due to its favorable properties. SBR rubber offers excellent abrasion resistance, good aging stability, and resilience, making it particularly suited for use in dynamic applications. Additionally, it performs well in various temperature ranges and is resistant to degradation from UV exposure and ozone, further enhancing its utility.

Characteristics of SBR Rubber Rolls

SBR rubber rolls are produced by rolling the material into large sheets, which can then be cut and molded according to the requirements of specific applications. These rolls typically exhibit the following characteristics

1. Durability SBR rubber rolls are tough and resistant to wear and tear. This makes them ideal for heavy-duty applications where robust material is essential.

2. Flexibility The flexibility of SBR rubber allows it to be used in scenarios that involve bending and shaping. This attribute is particularly useful in applications such as padding, flooring, and liners.

3. Cost-Effectiveness Compared to other types of synthetic and natural rubbers, SBR is relatively inexpensive to produce. This affordability makes SBR rubber rolls a popular choice among manufacturers aiming to optimize their material costs.

sbr rubber roll

4. Adaptability SBR rubber can be formulated and compounded with various additives to enhance specific properties, such as fire resistance, electrical conductivity, or enhanced chemical resistance. This versatility enables it to cater to a wide range of industrial needs.

Applications of SBR Rubber Rolls

SBR rubber rolls are commonly used in a variety of applications, including

- Tire Manufacturing SBR is a key component in the production of tires. Its durability and elasticity contribute to better traction and longer tire life.

- Conveyor Belts In industrial settings, conveyor systems require reliable materials for movement and handling. SBR rubber rolls provide the necessary strength and slip resistance to facilitate smooth operations.

- Flooring and Mats The shock-absorbing properties of SBR make it an excellent material for flooring solutions, especially in gyms and industrial workspaces where safety and comfort are critical.

- Insulation and Seals SBR’s resistance to various environmental factors makes it suitable for manufacturing seals and insulation materials, providing effective barriers in electrical and mechanical applications.

Conclusion

SBR rubber rolls are integral to many manufacturing processes and industrial applications due to their versatility, durability, and cost-effectiveness. From everyday products like tires and conveyor belts to specialized applications in flooring and insulation, the impact of SBR rubber cannot be overstated. As industries continue to evolve, the demand for high-quality materials like SBR rubber will likely remain strong, affirming its place as a foundational resource in modern manufacturing. Investing in SBR rubber rolls often leads to long-term benefits for businesses looking to innovate and expand their production capabilities while ensuring reliability and performance.