Dek . 11, 2024 09:55 Back to list

Customizable EPDM Composite Sponge Door Sealing Strips for Export Solutions

The Rise of Customizable EPDM Composite Sponge Door Sealing Strips A Game-Changer in the Global Market

In today's rapidly evolving construction and manufacturing industries, precision and adaptability are paramount. As businesses strive to optimize energy efficiency and enhance environmental comfort, one product that has gained significant traction is the customizable EPDM (Ethylene Propylene Diene Monomer) composite sponge door sealing strip. With impressive mechanical properties, durability, and versatility, these sealing strips are becoming an essential component for architects, builders, and manufacturers across various sectors.

Understanding EPDM Composite Sponge

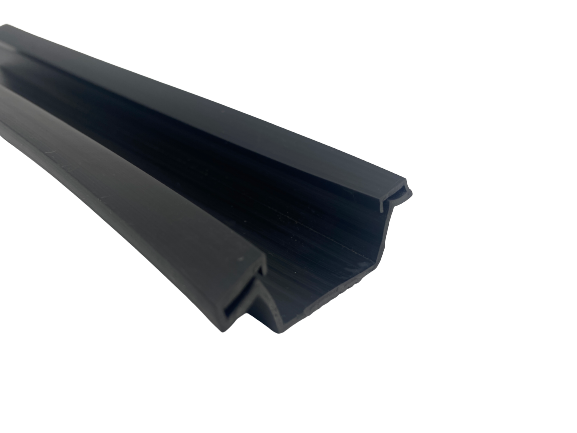

EPDM is a type of synthetic rubber known for its excellent resistance to heat, ozone, and weathering. When combined with a sponge structure, it offers unique benefits, making it an ideal material for door sealing applications. The composite nature of these sealing strips allows for enhanced flexibility and compression recovery, ensuring a tight seal that adapts well to the varied movements of doors over time.

Customizability Meeting Diverse Needs

One standout feature of EPDM composite sponge door sealing strips is their customizability. Manufacturers can produce these strips in a wide range of sizes, densities, and profiles to meet specific project requirements. This adaptability is crucial in a landscape where every building project has unique specifications and challenges. By offering customizable solutions, exporters can cater to diverse markets, including residential, commercial, and industrial sectors.

Benefits of Using EPDM Composite Sponge Sealing Strips

1. Energy Efficiency A well-sealed door can significantly reduce heating and cooling costs. EPDM composite sponge sealing strips form an airtight seal that prevents drafts, keeping indoor environments comfortable.

2. Sound Insulation These sealing strips also play a vital role in soundproofing. The sponge material dampens sound waves, making them an ideal choice for buildings in noisy urban areas or for spaces requiring privacy, such as offices and conference rooms.

customizable epdm composite sponge door sealing strip exporter

3. Durability and Longevity EPDM is highly resistant to environmental factors, including UV rays, extreme temperatures, and moisture. This durability ensures that sealing strips maintain their integrity over time, reducing the need for frequent replacements and repairs.

4. Easy Installation Customizable EPDM sealing strips are designed for quick and easy installation, which can significantly reduce man-hours and labor costs on construction sites.

5. Versatility These sealing strips can be employed in various applications, including residential doors, commercial entryways, industrial enclosures, and even vehicles, showcasing their broad applicability.

The Export Market for EPDM Composite Sponge Sealing Strips

As global awareness of environmental issues rises, the demand for energy-efficient building materials is at an all-time high. Exporters of customizable EPDM composite sponge door sealing strips are well-positioned to take advantage of this trend. The ability to offer bespoke solutions tailored to specific client needs makes these companies appealing in international markets.

Additionally, ongoing advancements in manufacturing technologies and materials science are enhancing the quality and performance of EPDM sealing strips. This progression, combined with effective marketing strategies, can help exporters penetrate new markets and increase their global footprint.

Conclusion

The shift towards energy efficiency and improved environmental comfort in building designs has led to a tremendous opportunity for customizable EPDM composite sponge door sealing strip exporters. As stakeholders in the construction and manufacturing industries become more aware of the benefits of these high-performance sealing solutions, the demand is expected to continue to grow. By focusing on customization and maintaining high-quality standards, exporters can ensure their products meet the evolving needs of a diverse clientele, driving growth and innovation in this essential market segment. The future looks bright for those who embrace these transformative materials and opportunities.